T00066GB

8

MAINTENANCE

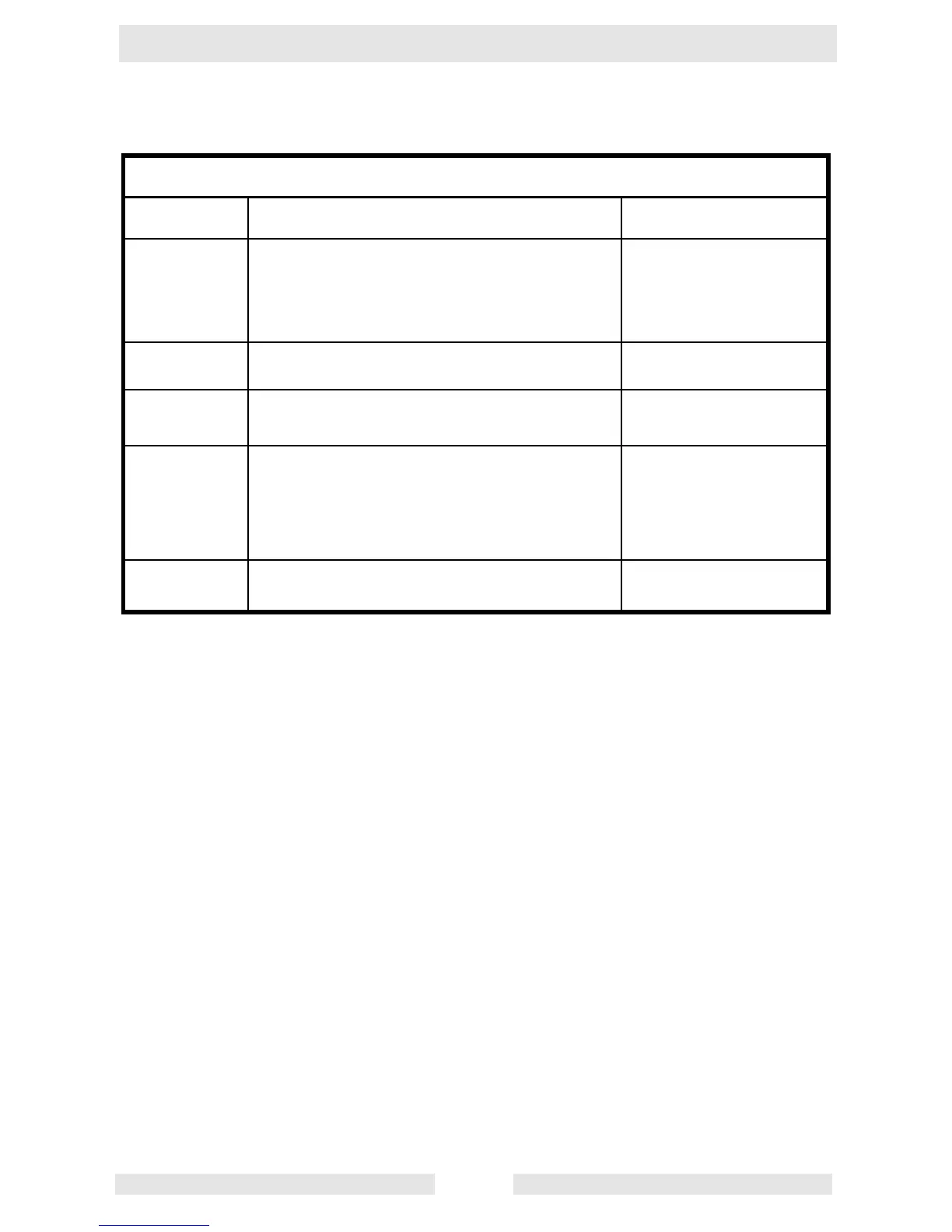

Maintenance schedule

Check all external screw connections for tight fit approx. 8 hours after first operation.

Component Maintenance work Maintenance interval

Feed line Check for perfect condition - if cable daily

defective, replace.

Miscellaneous Fan slits dirt - free - clean if necessary.

Tools Check the shafts and cutting edges - if necessary,

sharpen, reforge or replace.

Miscellaneous Regrease via grease nipples. 20 hours

Tool bush Check for wear - change if necessary. monthly

Carbon brush Check for wear, remaining length about 9 mm 80 hours

- change if necessary.

Miscellaneous Check cheese head screws of housing for tight

fit retighten if necessary - 25 Nm.

Miscellaneous Regrease crankshaft drive. 600 hours

Maintenance and lubrication

1. General instructions

Keep hammer and tools clean.

2. Motor

Carbon brushes: This hammer is equipped with automatic switch-off carbon brushes. Thes brushes switch-

off the hammer as soon as their length is worn down to approx. 9 mm. Therefore, before starting a long

operation check brushes for wear. Replace if necessary.

3. Mechanical part

Every 20 hours of operation moderately grease crank mechanism and percussion system via lubricating

nipple situated on crankcase (see technicla data). Use special grease. Check tool holder brushing for wear.

The tool may have a play of max. 6 mm at a distance of approx. 200 mm from the entrance. If the bushing

is worn to a greater degree, replace it to avoid damages and operational failures.

Loading...

Loading...