12

EN

SPRAYER CONTROLS

XBOOST™ FLOW CONTROL

The X-Boost™ ow control adjusts the level of air ow produced by the turbine.

Pressing

the (+) button will increase the air ow. Pressing the (-) button will decrease the air ow.

The indicator bars will light up and show the air ow the turbine is currently spraying.

Whenever the turbine is turned ON, the air ow will automatically be set to 3 bars

(medium air ow).

• A high air ow level will result in faster coverage and a smoother nish with thicker

materials.

• Lowering the air ow will result in larger drops of material being sprayed from the

gun, and will create a slightly rougher nish.

Tip: The thicker the material you are spraying, the higher the turbine

air ow

you will need.

Tip: For ne-nish work with thinner materials, you may want to decrease the air

ow

. Spraying a thinner material at high air

ow

will result in more overspray. Overspray is sprayed material that does not stick to the spray surface and bounces back.

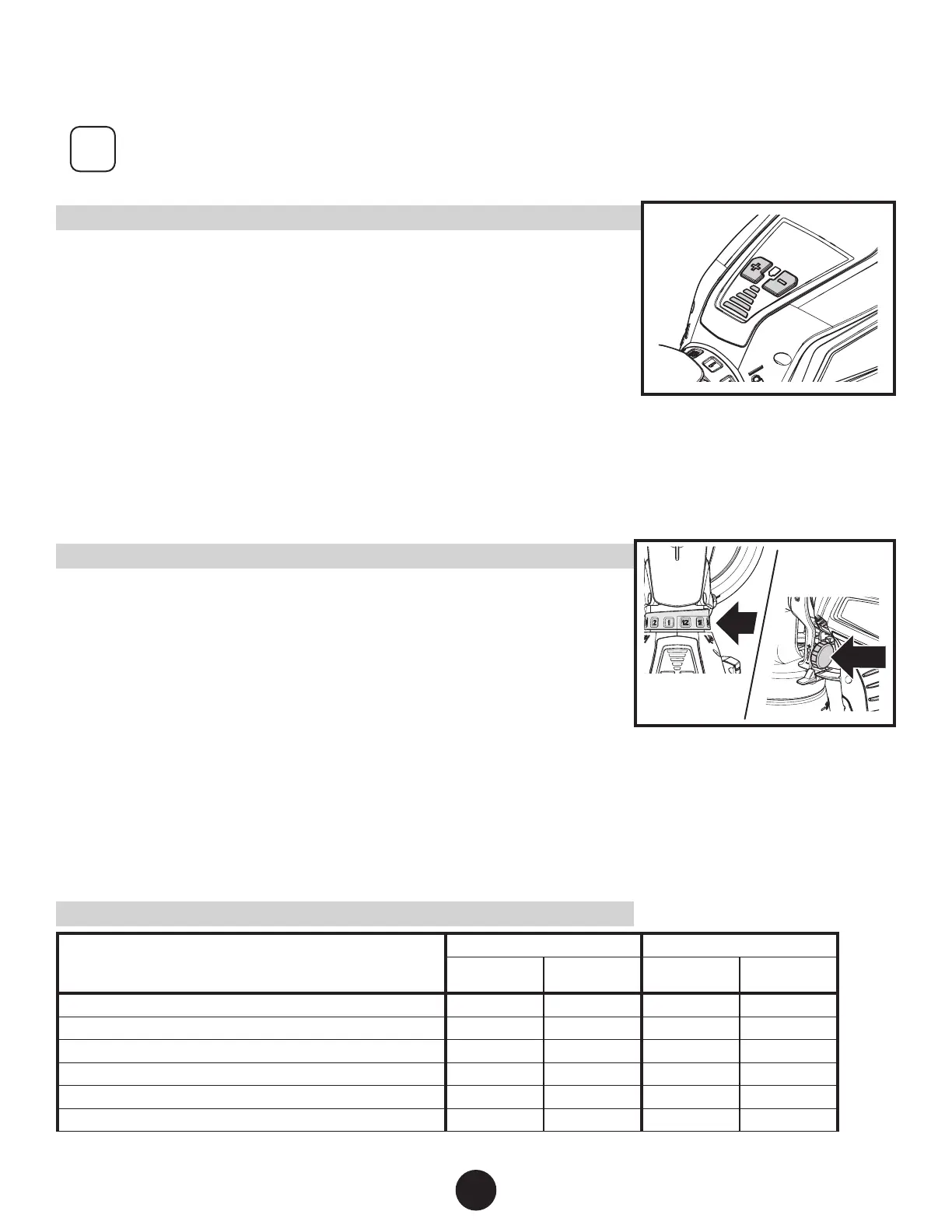

MATERIAL FLOW CONTROL

The material ow control determines the amount of spray material that is sprayed

from the spray gun.

iSpray Nozzle - The material ow can be adjusted incrementally from 1 (minimum) to

12 (maximum) by turning the adjustable material ow control

Detail Finish Nozzle - Set the material ow by turning the grey knob on the trigger

of the spray gun.

• For thicker materials, it is recommended that you start with the highest material

ow setting and then gradually decrease the ow to suit your particular spraying needs.

• For thinner materials, it is recommended that you start with a low material ow setting, and then gradually increase the ow

to suit your particular spraying needs.

• The higher the ow setting, the quicker you will have to work in order to avoid drips and sags in your spray pattern.

Tip: Spraying with the control set too high will result in a spray pattern that runs and sags (too much material).

Tip: Spraying with the control set too low will result in a spray pattern that does not cover (not enough material).

AIR AND MATERIAL SETTINGS GUIDE

Coating

iSpray Nozzle Detail Finish Nozzle

Material Flow Air Flow

(# of bars)

Material Flow Air Flow

(# of bars)

Transparent / semi-transparent stains, sealers 2 1-2 Med/Heavy 1-3

Lacquers (water based) 3 1-2 Med/Heavy 1-3

Solid stains 4 - 6 2-4 Med 2-4

Polyurethane 4 - 6 3-5 Med/Heavy 3-6

Oil enamels 7 3-5 Heavy 3-5

Latex paints plus primers, Latex paints, oil or latex primers 9 - 11 3-5 Heavy* 5

iSPRAY

DETAIL FINISH

Spray performance will depend upon a number of factors: material thickness, air ow, spray pattern selected,

and material ow. Testing dierent variations of the control settings will help you achieve the desired results.

See descriptions and suggested Air and Material Settings Guide below to help with your project.

* spray material needs to be thinned

Loading...

Loading...