GB

23

W 450

•

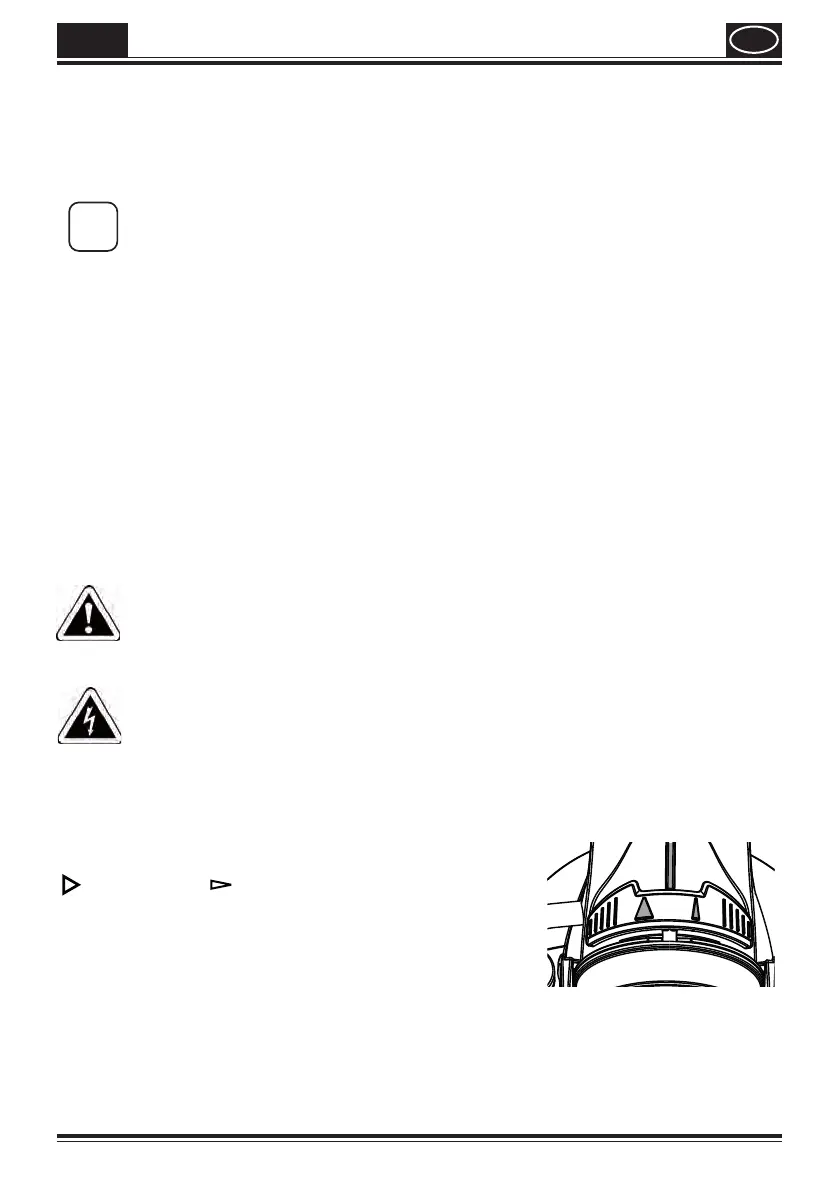

Aligning suction tube. (Fig. 3)

If the suction tube is positioned correctly, the container contents can be sprayed

without almost any residue.

When spraying horizontal surfaces, turn suction tube forward. (Fig. 3 A)

When spraying objects overhead, turn suction tube back. (Fig. 3 B)

i

We recommend orienting the feed tube to the rear, to ensure optimal

coating of walls and ceilings.

•

Place the container on a paper base and pour in the prepared coating substance with

the aid of the feed hopper included in the scope of supply (Fig. 1, 18).

Screw the container tightly onto the spray gun.

•

Connect the front part with the rear part of the gun. (Fig. 5)

•

Mount the air hose (Fig. 4, a + b). Insert the air hose rmly into the connection of the

unit and the gun handle. The position of the hose is not relevant.

•

Put the machine down only on a level, clean surface. Otherwise, the gun may suck in

dust, etc.

•

Sling on the carrying strap with the unit.

•

Press the ON/OFF switch at the device.

12. Selecting the Spray Setting (Fig. 6)

WARNING! Danger of injury! Never pull the trigger guard while adjusting

the air cap.

2 dierent spray jet shapes can be set by turning the air cap (g. 6, 1)

Tighten the union nut (Fig. 6, 2) fully so that no paint is able to penetrate

the device. Check regularly whether the union nut has worked loose during

operation.

Fig. 7 A = vertical at jet

for horizontal surfaces

Fig. 7 B = horizontal at jet

for vertical surfaces

Use the red adjustment lever to also switch between a wide

( ) and a narrow ( ) spray jet.

13. Adjusting the Material Volume (Fig. 8)

The volume of material can be set by turning the material volume control (Fig. 8, 1) in

steps from 1 (minimum) to 12 (maximum).

Loading...

Loading...