Operating Instructions

WE225, WE235

Trailer Wood Splitter

26

IMPORTANT! Do not operate machine if oil level is

not visible on the dipstick. Damage to the pump and

other components can occur.

• Do not overll the tank past the full mark.

• Always check oil levels after changing lters

or servicing hydraulic components.

• Hydraulic oil quality should be inspected

every 40 hours. If the oil is dirty or smells

burnt, it should be replaced.

• Be aware of high oil temperatures.

Temperatures higher than 180 °F (82 °C) could

cause seal damage and degrade oil quality.

6.6.1 Hydraulic Oil – Adding

The hydraulic system uses Dexron® III ATF.

1. Clean the area around ller cap and remove it.

2. Use a clean funnel and add oil until the level is at the

full mark on the dipstick.

3. Install ller cap securely. Wipe up any spilled oil.

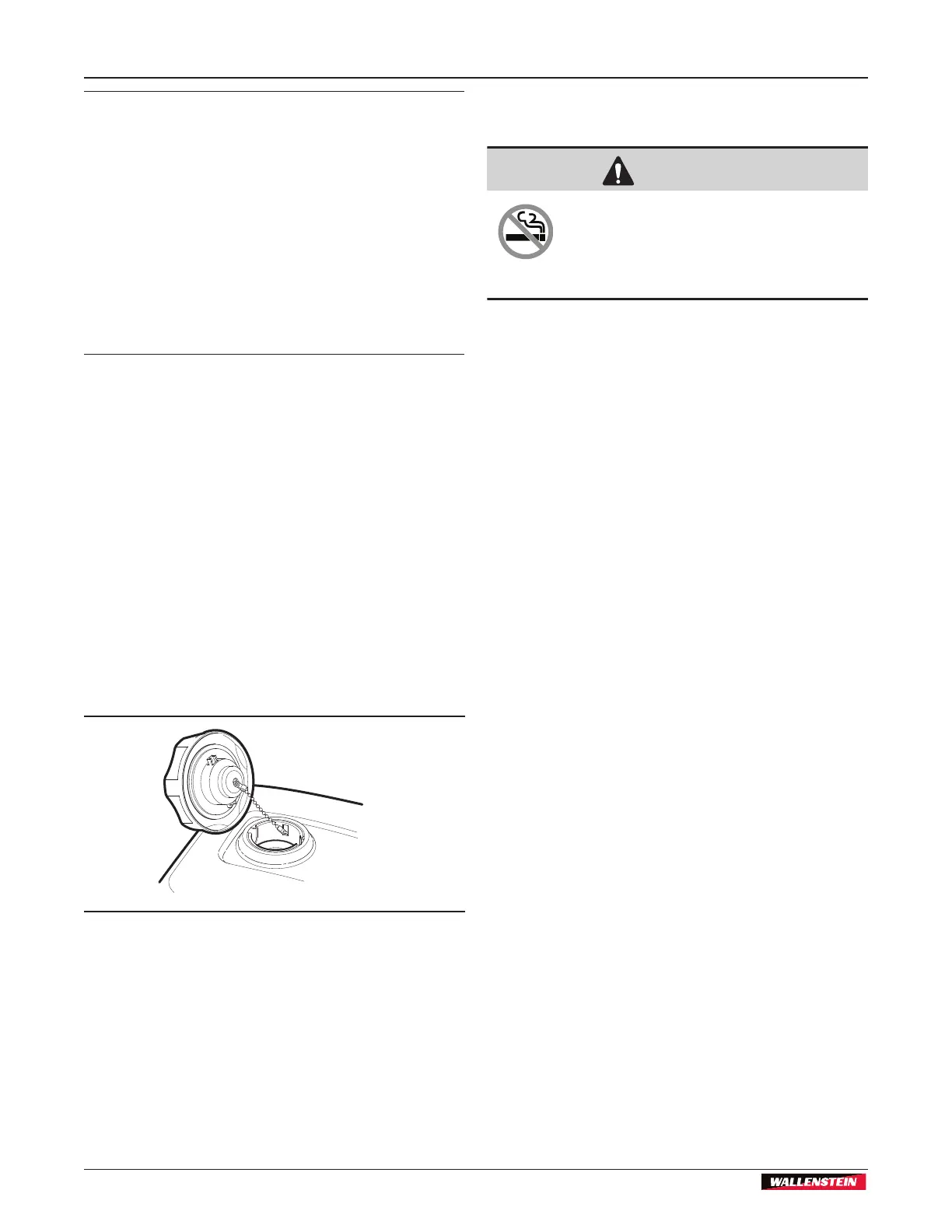

6.7 Fuel Level Check

Check the fuel level daily.

Starting with a full tank helps to eliminate or reduce

operating interruptions for refueling.

The fuel tank is located on the engine. Avoid running the

tank dry.

00198

Fig. 17 – Fuel Filler Cap

6.7.1 Refueling

Fuel tank capacity: 0.25 US gal (0.93 L).

WARNING!

Fuel vapors can explode causing

injury or death. Do not smoke while

refueling. Keep sparks, fl ames, and hot

components away.

W027

Refuel in a well-ventilated area with the engine stopped.

If the engine has been running, allow it to cool rst. Never

refuel the engine inside a building where gasoline fumes

can come in contact with ames or sparks.

For fuel specication, see Fluids and Lubricants on

page 33 . Refer to the engine manual for additional

information on fuels.

1. Clean the area around fuel tank cap. Fill the tank

to 1/2" (12 mm) below bottom of ller neck to

provide space for any fuel expansion. Do not

overll.

2. Install fuel ll cap securely and wipe up any spilled

fuel.

Loading...

Loading...