WE225, WE235

Trailer Wood Splitter

Service and Maintenance

37

8.7 Engine Air Cleaner

Check air lter every 40 hours of operation. Change

air lter elements at 100 hours of operation or

annually.

NOTE:

Refer to the engine manual for information

on servicing the air cleaner.

A dirty air lter can restrict air ow to the carburetor,

reducing engine performance. If the engine is operated

in very dusty areas, clean the air lter more often than

specied.

IMPORTANT! Operating the engine without an air

lter, or with a damaged air lter, can allow dirt to

enter the engine, causing rapid engine wear. This

type of damage is not covered by Warranty.

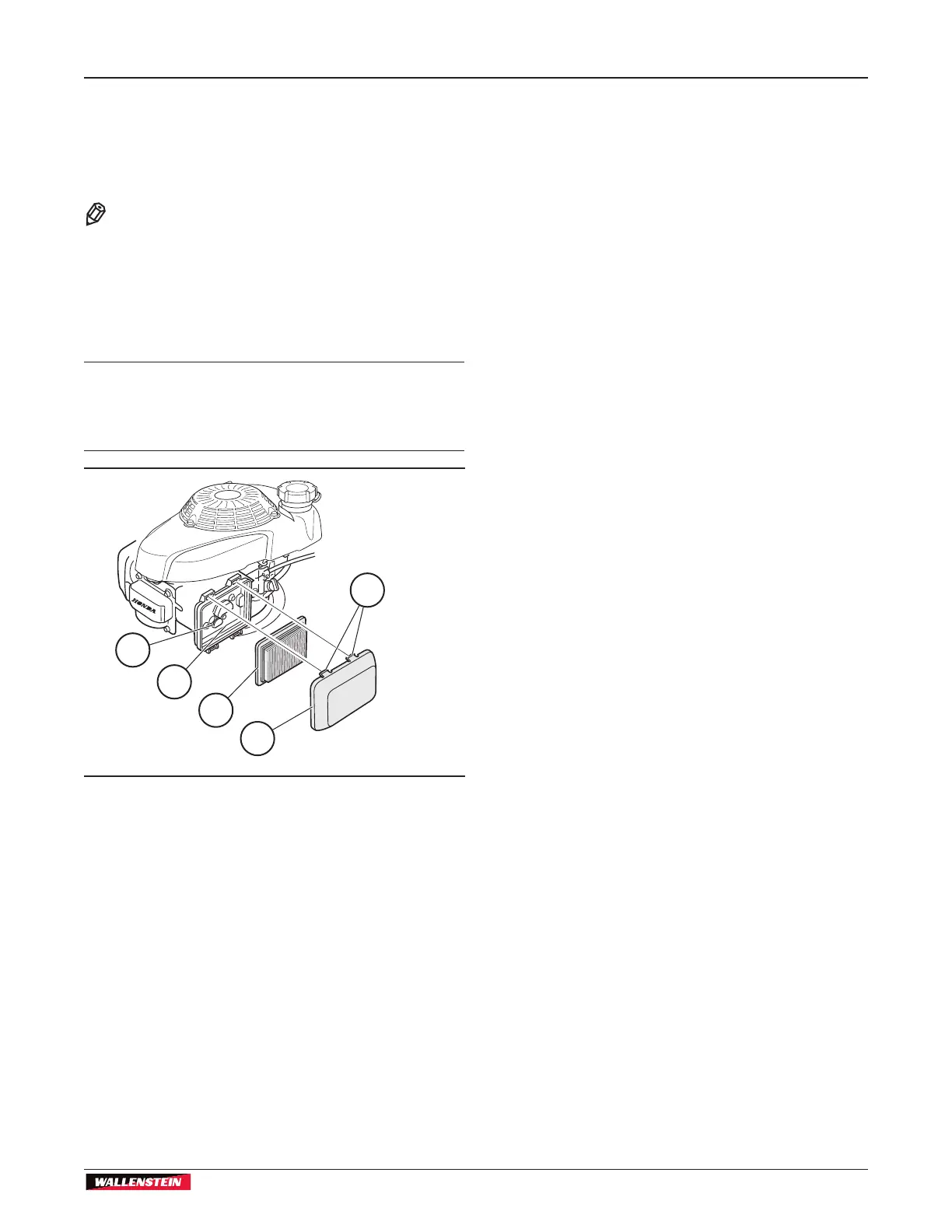

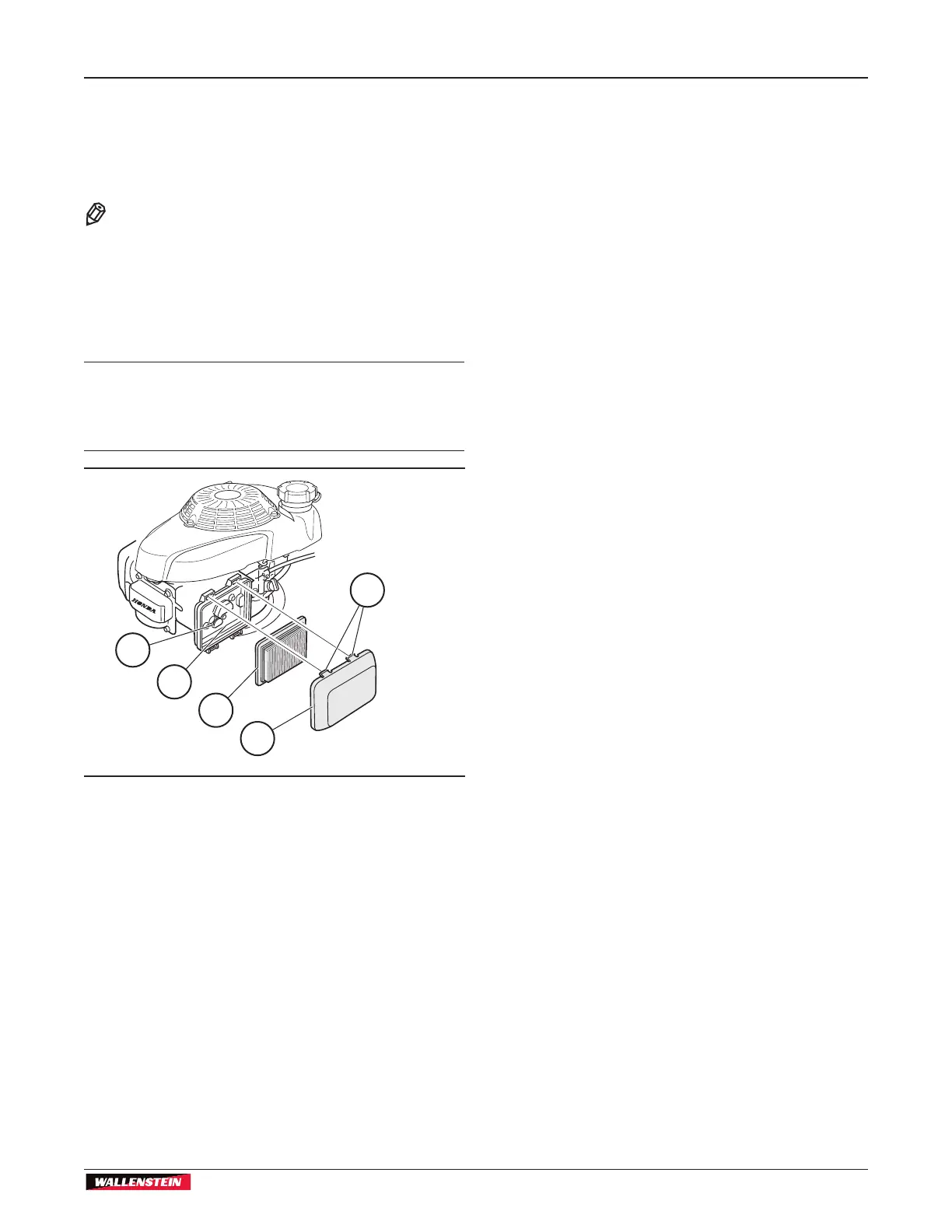

00712

1

2

3

4

5

Fig. 34 – Engine Air Cleaner

1. Tabs on Cover

2. Air Cleaner Cover

3. Filter Element

4. Air Cleaner Body

5. Carburetor Duct

Inspection

Remove the air cleaner cover and inspect the lter

element. Clean or replace dirty lter elements. Always

replace damaged lter elements.

1. Press the latch tabs (1) on the top of the air cleaner

cover (2), and remove the cover. Check the lter (3)

to be sure it is clean and in good condition.

2. Reinstall the lter and air cleaner cover.

Cleaning

3. Tap the lter several times on a hard surface to

remove dirt, or blow compressed air not exceeding

30 psi (207 kPa) through the lter from the clean

side that faces the engine. Never try to brush off dirt.

Brushing will force dirt into the bers.

4. Wipe dirt from the air cleaner body (4) and cover

using a moist rag. Be careful to prevent dirt from

entering the air duct (5) that leads to the carburetor.

Loading...

Loading...