OPERATING INSTRUCTIONS

9

OPERATING INSTRUCTIONS

8

CLEANING

• Use low pressure water to clean synthetic rope.

Do not use any chemicals.

• Do not direct high pressure water (pressure

washers, car washes, etc.) directly between the

drum support and drum flange or clutch lever.

• Use low pressure water and a soapy rag or

sponge to clean the winch.

• Avoid using chemicals that may damage the

finish.

• Thoroughly clean salt residue from the winch as

soon as possible to minimize corrosion.

BATTERY RECOMMENDATIONS

A fully charged battery and good connections are

essential to the proper operation of your winch. The

minimum requirement for a 12 volt DC battery is

650 Cold Cranking Amperes.

ROPE INSPECTION

When rope is first used, the outer filaments of the

rope will quickly fuzz up. This is the result of these

filaments breaking and this roughened surface will

actually protect he fibers underneath. The condition

should stabilize, not progress. If the surface

roughness increases, excessive abrasion is taking

place and strength is being lost.

Look closely at both the inner and outer fibers. When

either is worn the rope is obviously weakened. Open

the strands and look for powdered fiber—this is a

sign of internal wear.

Rope should be replaced when:

• Rope bulk anywhere along the length is reduced by

10% or more by abrasion.

• Two or more adjacent strands are cut.

• Flat areas or lumps are found that are not

eliminated by flexing rope.

• Excessive fused or melted fibers are found. Any

such areas will be stiff and the rope will have a

glazed appearance.

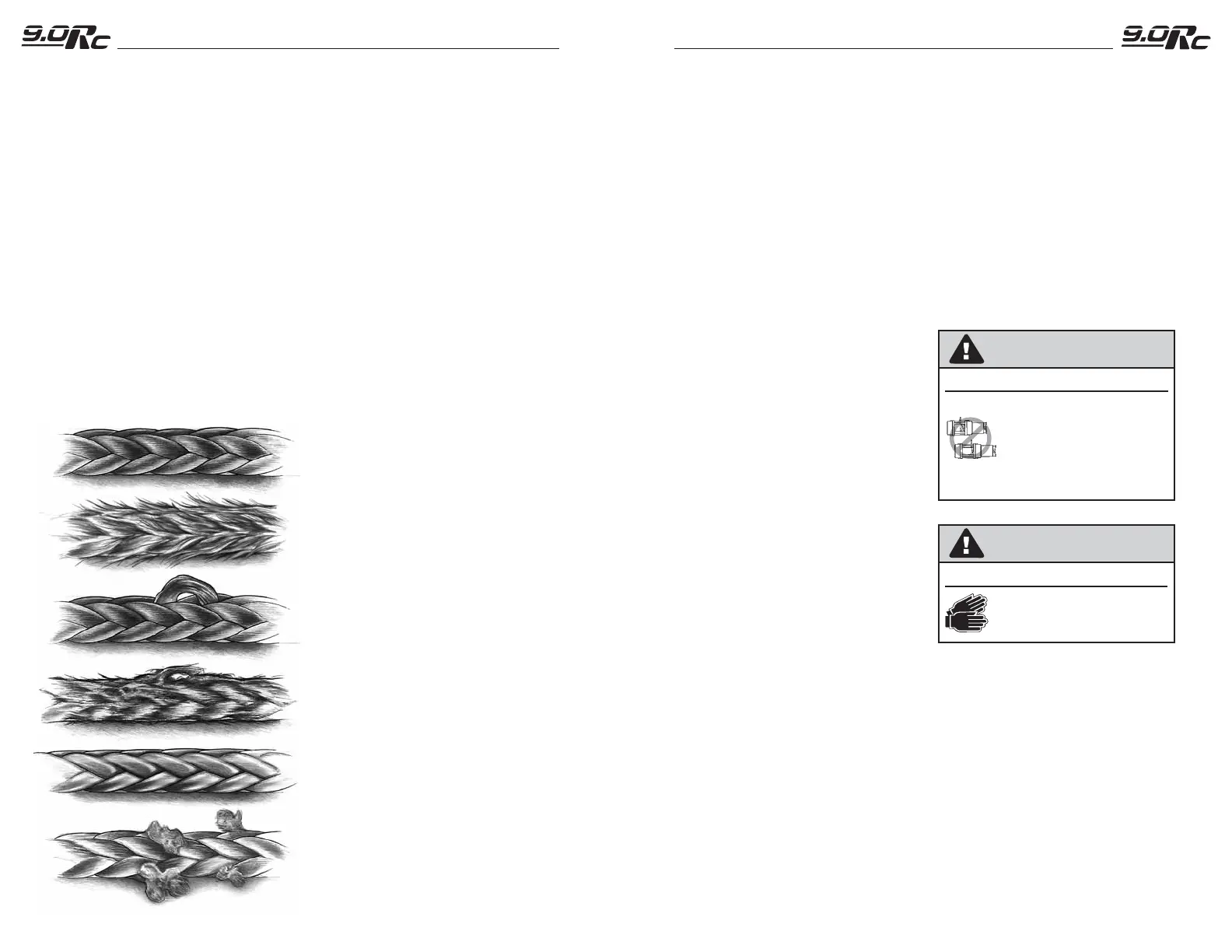

Rope with original bulk.

Rope displaying 25% strand volume reduction from

abrasion—

rrooppee sshhoouulldd bbee rreeppllaacceedd..

Rope strand showing full volume.

Rope strand reduced by 25% abrasion—

rrooppee

sshhoouulldd bbee rreeppllaacceedd..

Rope exhibits fiber-set from compression. A slight

sheen is visible. This is not a permanent

characteristic and can be eliminated by flexing the

rope.

Rope displays two adjacent cut strands—

rrooppee

sshhoouulldd bbee r

reeppllaacceedd..

MAINTENANCE

• Replace rope every 12 months with P/N 71717.

• No lubrication is required for the life of the winch,

unless the winch is submerged in water. If this

occurs, a qualified service center must complete

service as soon as possible to prevent corrosion

damage. If the control pack is submerged, it must

be replaced when the winch is serviced.

• Check battery cables and electrical connections at

90 day intervals to be certain they are clean and

tight at all connection points.

• Inspect the rope before and after each winching

operation. Frayed or damaged rope must be

replaced immediately. See rope care and storage.

• The rope must always spool onto the drum as

indicated by the drum rotation decal on the winch.

ROPE STORAGE AND CARE

To ensure safety and performance, the inspection

and maintenance of winching rope should be among

every user’s primary concerns.

1. Inspect your winch rope for breaks, cuts,

abrasion and melted or fused fibers before each

use.

2. Wash rope periodically to remove dirt and grit.

Simply rinse rope with a garden hose, and allow it

to air-dry.

DO NOT

Use solvents, bleach or harsh detergents when

washing rope, and never apply a heat source to

speed drying.

3. Coil rope loosely, for storage, being sure to

remove any excess twists. To maximize rope life,

always store rope line in a dark, dry place. Before

using any rope, refer to the following guide.

If the rope is damaged, remove it from service

immediately, and replace it with undamaged rope,

Warn P/N 71717. Broken or cut strands reduce

the rope’s strength throughout its length — not

just in the area of damage. As a general rule,

retire your 12 strand rope when more than 3

broken or cut strands are visible, or if two

adjacent strands are compromised.

4. Replace your rope every 12 months with only

Warn rope, P/N 71717.

NORMAL WEAR

When small surface fibers break on a rope, they

create a fuzzy texture. Known as “mild abrasion,”

this is considered good wear, and will not affect the

performance of the rope. The nubby surface actually

protects the underlying fiber from further wear.

EXCESSIVE WEAR – RETIRE THIS ROPE

When fibers are melted or fused, it is generally the

result of rope abuse. Melted or fused polyester

fibers result from bringing the rope’s surface to a

temperature in excess of 430° F.

Caused by excessive load weights or powering out,

these damaged fibers can compromise strength,

and should signal the rope’s retirement.

CHEMICAL ATTACK – RETIRE THIS ROPE (NOT

ILLUSTRATED)

Localized discolorations could potentially represent

chemical attack by anything from gear oil to

battery acid. When doubt exists, retire the line.

OPERATOR’S SAFE WORKING STATIONS

The operator should always operate the winch in a

safe position while pulling a load. The safe areas are

perpendicular to the rope or in the vehicle with the

hood up (if winch is mounted on front of vehicle).

This will help prevent the rope from striking the

operator if it fails under load. Operate the winch,

when possible, at the end of the remote control

length. The operator must be at least 8 ft (2.44m)

from the winch while operating. This will prevent

entanglement with the fairlead and keep the

operator out of harms way during winch load pulling.

Never work around rope while under load.

WINCHING

Examples:

• Never operate winch with

less than 8 wraps of rope

around the drum. Rope could

come loose from the drum,

as the rope attachment to

the drum is not designed to

hold a load.

To avoid severe injury or death:

WARNING

• Always wear heavy leather

gloves when handling a

wire rope.

To avoid minor or moderate injury:

CAUTION

Loading...

Loading...