Page 12 ;&(%$*4.8"4,7%<'*#$"&8#=%/7*,#*%4,77%>?@@@?@AA?BCDC1 Item 57342

EF;6GH IJ6KFGLIM NFLMG6MFMO6E6GPJ

6##*8$",7%E$(,"3.$%J'#.?#$"4X%;*,$'(*#%,89%;'84$"&8#

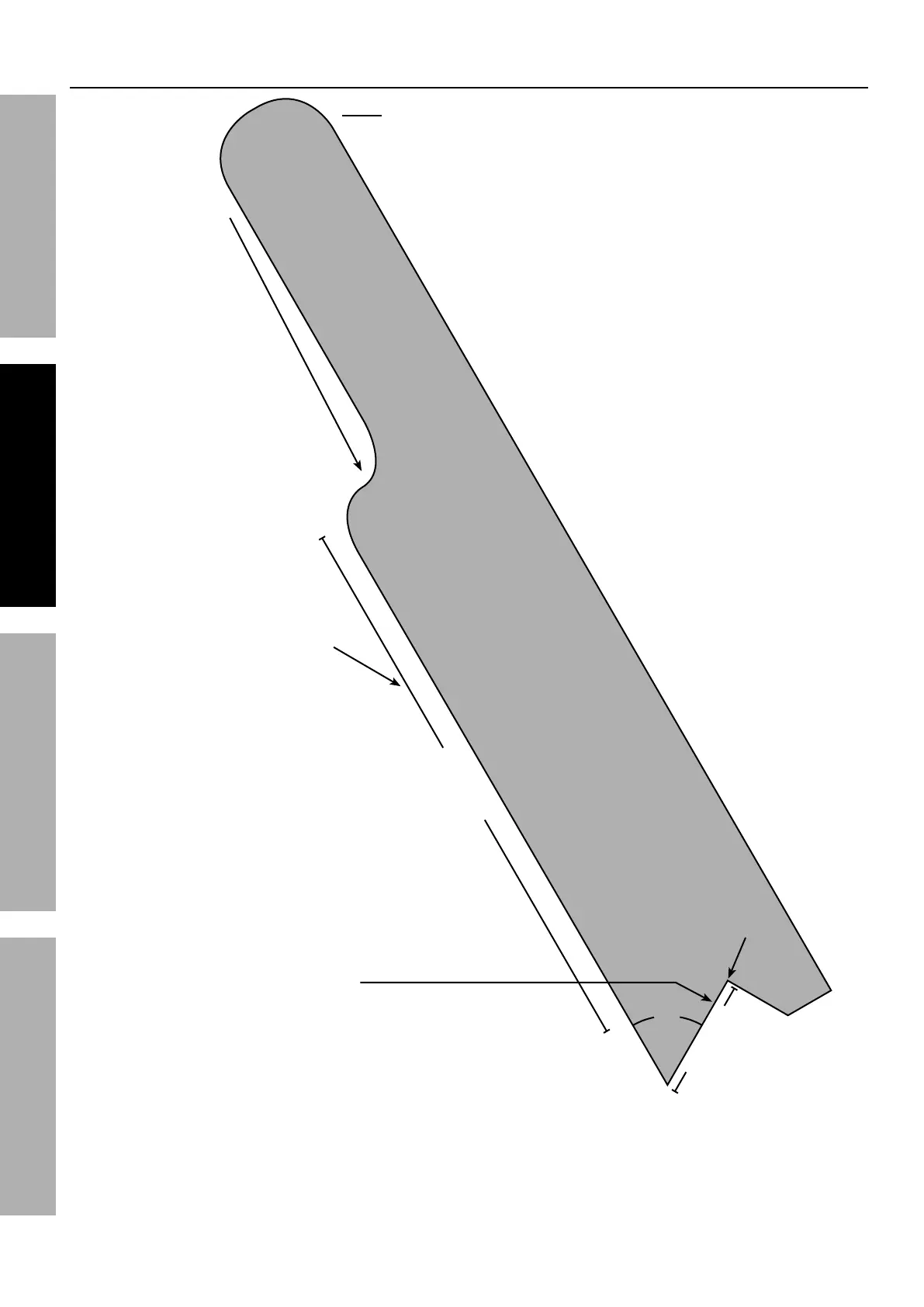

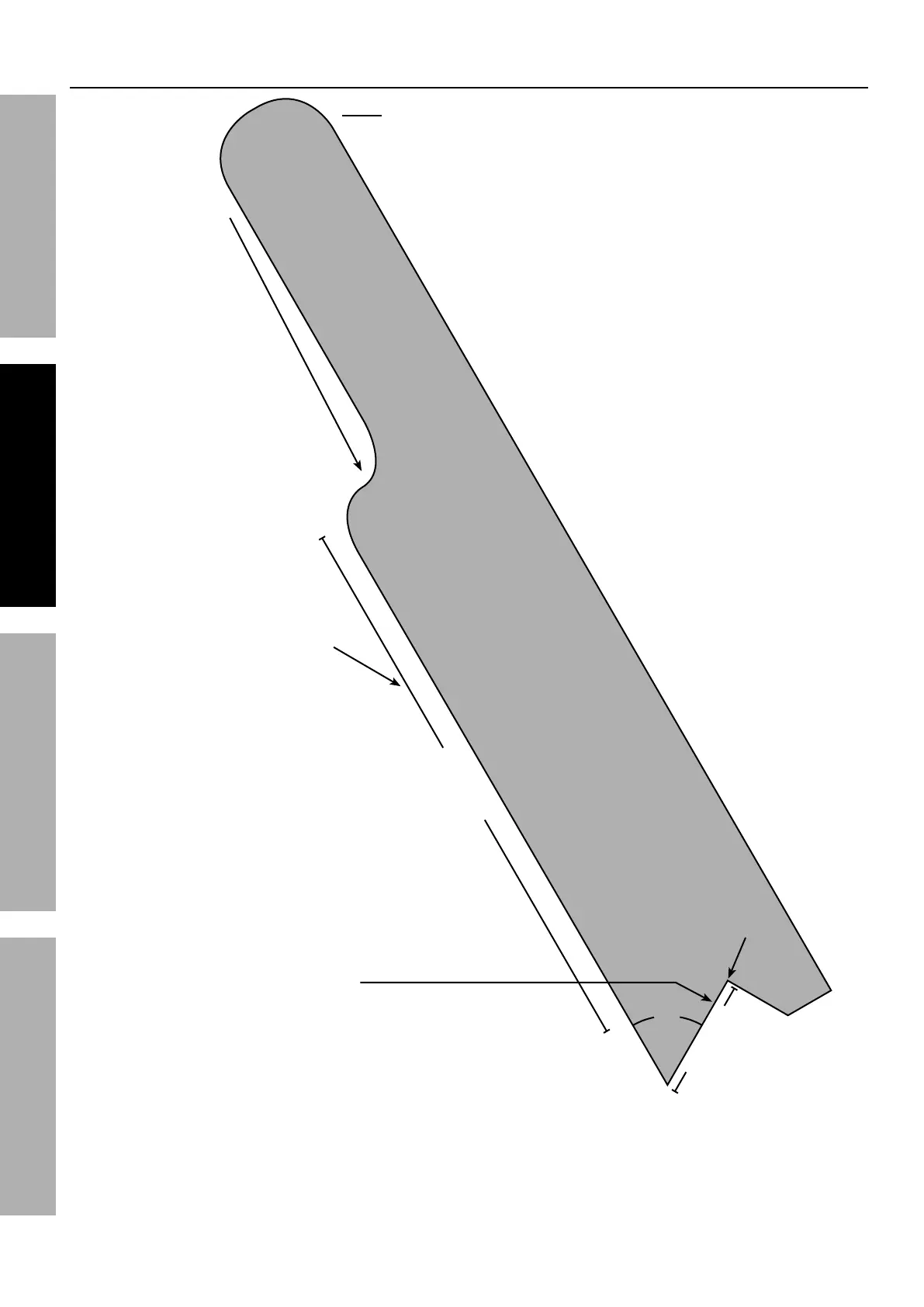

M&$*- Straight style (traditional) stick shown. A different stick design

may be used if it properly protects against all hazards.

U",3(,5%8&$%$&%#4,7*1

• Push sticks must be made from sturdy, defect-free, plywood or

normal wood to prevent unexpected breakage. Material must

be at least 1/4″ thick, but no thicker than the finished wood.

• Inspect push stick before use and do not use

a damaged or deteriorated push stick.

• Push stick dimensions will vary depending

on the application and user.

_,897*%M&$4.

• Must be far

enough down

the stick to allow

a comfortable

and firm grip.

• Must be deep

enough to prevent

hand from slipping

down the stick.

• Do not cut more than

halfway into the stick

to prevent weakening.

• Corners may

be rounded to

increase comfort.

E$"4X%T*83$.

• Must be long enough

to keep hand

clear of blade.

• At least 6″ from end

of handle to closest

part of notch.

M&$4.

• Must be right (90°) angle, cut at 30°-40° from the angle

of the stick to keep hands out of the line of the blade.

• The lower lip of the notch must be no

longer than the workpiece is thick.

At Least 6″

T*##%$.,8%

)&(X/"*4*%

$."4X8*##

MIG%GI%EOFT61MIG%GI%EOFT61

Dfm

nfm?gfmnfm?gfm

Loading...

Loading...