What causes too high lubricating oil temperature in WÄRTSILÄ Engine?

- NNicole GarciaSep 10, 2025

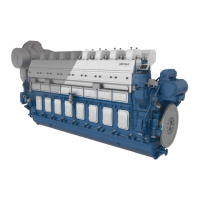

Excessively high lubricating oil temperature in a WÄRTSILÄ Engine can be attributed to a faulty thermometer, insufficient cooling water flow through the oil cooler (due to a faulty pump, air in the system, or a closed valve), a clogged oil cooler, or a faulty thermostat valve.