Do you have a question about the Wartsila Vasa R22 and is the answer not in the manual?

Overview of the structure and purpose of the instruction book, including engine operation and maintenance data.

Essential guidelines for handling and maintenance work, emphasizing cleanliness and safety protocols.

Definitions of key terms used in the manual, such as 'driving end', 'free end', 'TDC', and 'BDC'.

General safety instructions and an overview of identified hazards and hazardous situations during operation and maintenance.

Information on engine identification, including engine type designation and stroke specifications.

Key technical specifications of the VASA 22 and VASA 22/26 engines, including cylinder bore, stroke, and firing order.

Recommended operating parameters for the VASA 22 engine, covering temperatures and pressures under normal and alarm conditions.

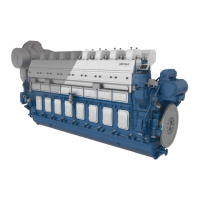

Detailed description of the engine's general design, including its turbocharged, intercooled 4-stroke diesel configuration.

Information on fuel types, characteristics, and general handling requirements for the engine.

Procedures for fuel purification and heating, including recommended temperatures and flow rates for centrifuging.

Details on system oil characteristics, including viscosity, alkalinity, and required additives for optimal performance.

Guidelines for cooling water treatment, including general requirements, additives, and handling precautions.

Procedures for starting the engine, including pre-start checks, manual start, and remote/automatic start operations.

Instructions for stopping the engine, covering both manual and remote stop procedures.

Guidelines for monitoring engine operation, including checks on temperatures, pressures, and load indicators.

Procedures for running-in a new engine or after major maintenance, emphasizing load variation and ring seating.

General principles for the maintenance schedule, emphasizing safety and adherence to intervals.

Tasks to be performed at 50 operating hour intervals, covering checks on air coolers, cooling system, and connecting rods.

Maintenance tasks required at 1000 operating hour intervals, including oil changes and filter replacements.

Major maintenance schedule item for 48000 operating hours, focusing on balancing shaft inspection.

Introduction to specialized tools required for engine maintenance, including selection and ordering information.

List and illustrations of tools specifically for main bearing maintenance.

Tools required for cylinder liner maintenance, including honing and extracting equipment.

Overview of various tightening tools, including torque wrenches and socket sets, for precise assembly.

Procedures for adjusting engine parameters such as valve timing, clearances, and fuel rack positions.

Table detailing critical dimensions, normal clearances, and wear limits for engine components.

Specifications for tightening torques for various screw connections on the engine, with diagrams.

Detailed tightening torques and procedures for the flywheel assembly.

Tightening specifications for the camshaft and associated control mechanism components.

Torque values for the injection pump fastening and cover screws.

Procedures for tightening connections using hydraulic tools, including filling and reassembly steps.

A comprehensive guide to diagnosing and resolving common engine operating problems and their possible causes.

Procedures for operating the engine under emergency conditions, such as with defective components.

Overview of the engine block construction, main bearings, cylinder liners, and oil sump design.

Detailed procedures for dismantling, inspecting, and installing main bearings and thrust washers.

Instructions for honing, removing, and mounting cylinder liners, including cleaning and lubrication steps.

Description of the crankshaft, including its forged construction, counterweights, and flywheel attachment.

Procedure for checking and adjusting crankshaft alignment using dial indicators.

Details on the connecting rod and piston assembly, including removal, maintenance, and installation steps.

Explanation of the balancing mechanism in 4-cylinder engines, including its components and operation.

Description of the cylinder head, including its construction, valve arrangement, and cooling system.

Step-by-step instructions for removing and installing the cylinder head, including fluid draining and reassembly.

Information on inlet and exhaust valves, their seat rings, dismantling, checking, and reconditioning procedures.

Description of the camshaft driving gear system, including its components and how it is driven.

Details on intermediate gears and the camshaft gear, including basic adjustment of valve timing.

Procedures for removing and mounting the split gear wheel, including cleaning and checking measurements.

Description of the valve mechanism, its function, and maintenance procedures.

Description of the camshaft, including its construction and procedures for removing and mounting camshaft pieces.

Procedures for inspecting, removing, and mounting camshaft bearing bushes.

General description of the turbocharger, its function, and components.

Guidelines for turbocharger maintenance, including normal overhauls and dismantling procedures.

Procedure for cleaning the turbine side of the turbocharger using water injection.

Maintenance procedures for the charge air cooler, including general checks and cleaning of the cooler insert.

Overview of the high-pressure fuel system, including injection pumps, pipes, and valves.

Detailed description of the injection pump's function and general construction.

Procedures for maintaining the injection pump, including removal, mounting, and fuel delivery control.

Information on the injection valve, including its general description, removal, and overhauling process.

Overview of the fuel system, including its design for heavy fuel duty and components like the fuel feed pump.

General maintenance guidelines for the fuel system, emphasizing cleanliness and regular filter changes.

Procedures for venting the fuel system, particularly after filter changes or when dealing with air in the system.

Instructions for adjusting fuel system pressure control valves to maintain correct operating pressures.

Description of the duplex fuel filter and procedures for changing filter cartridges.

Description of the lubricating oil system, including the oil pump, cooler, filters, and distributing pipes.

General maintenance recommendations for the lubricating oil system, emphasizing oil quality and level checks.

Description and dismantling/assembly procedures for the lubricating oil pump.

Description and maintenance of the lubricating oil pressure control and safety valve.

Description and maintenance procedures for the tube cooler used in the lubricating oil system.

Description of the lubricating oil main filter and procedures for changing filter cartridges.

Description and cleaning procedures for the centrifugal filter used in the lubricating oil system.

Description and maintenance procedures for the prelubricating pump.

Overview of the engine's cooling water system, divided into high (HT) and low (LT) temperature circuits.

General maintenance guidelines for the cooling water system, including cleaning and treatment recommendations.

Description and maintenance procedures for the centrifugal water pump.

Description and maintenance of the temperature control system, including thermostatic valves.

Description of the exhaust system, including pipes, metal bellows, and insulation box.

Instructions for replacing expansion bellows in the exhaust system.

Overview of the starting air system, including its components and pressure requirements.

Description and maintenance procedures for the main starting valve.

Description and maintenance of the starting air distributor, including piston guidance and air flow control.

Description and maintenance of the starting valve located in the cylinder head.

Guidelines for the starting air vessel and piping, emphasizing safety and cleanliness.

Description of the pneumatic system for engine control functions, including solenoid valves and filters.

Description of the engine speed control mechanism, including the speed governor and fuel rack control.

General maintenance for the control mechanism, focusing on friction, clearances, and regular checks.

Procedures for checking and adjusting control mechanism settings, including stop lever and governor positions.

Checks and adjustments for the mechanical overspeed trip device, including stop position and tripping speed.

Checks and adjustments for the electro-pneumatic overspeed trip device, including stop position and tripping speed.

Information on the speed governor, including its drive unit and procedures for removal and mounting.

Overview of instruments mounted on the engine, including manometers, thermometers, and switches.

Description of the instrument panel layout and its included instruments.

Details on alarm switches, stop switches, and indicating switches used for engine monitoring.

Introduction to the DESPEMES system for measuring engine speed and controlling relay functions.

Troubleshooting procedures for common issues with the Despemes system components.

Loading...

Loading...