5. COLD WATER SUPPLY

DO NOT CONNECT DIRECTLY TO WATER MAINS SUPPLY

DO NOT USE ANY JOINTING COMPOUNDS

The cold water supply to the pump must be connected using 22mm pipe, to the cold water

tank (do not connect to the central heating header tank!) see Fig 1. The tank connector

should be positioned at least 25mm (1”) lower than the cold water feed to the hot water

cylinder, to prevent the supply of hot water only.

6. CONNECTING PUMP

DO NOT USE ANY JOINTING COMPOUNDS

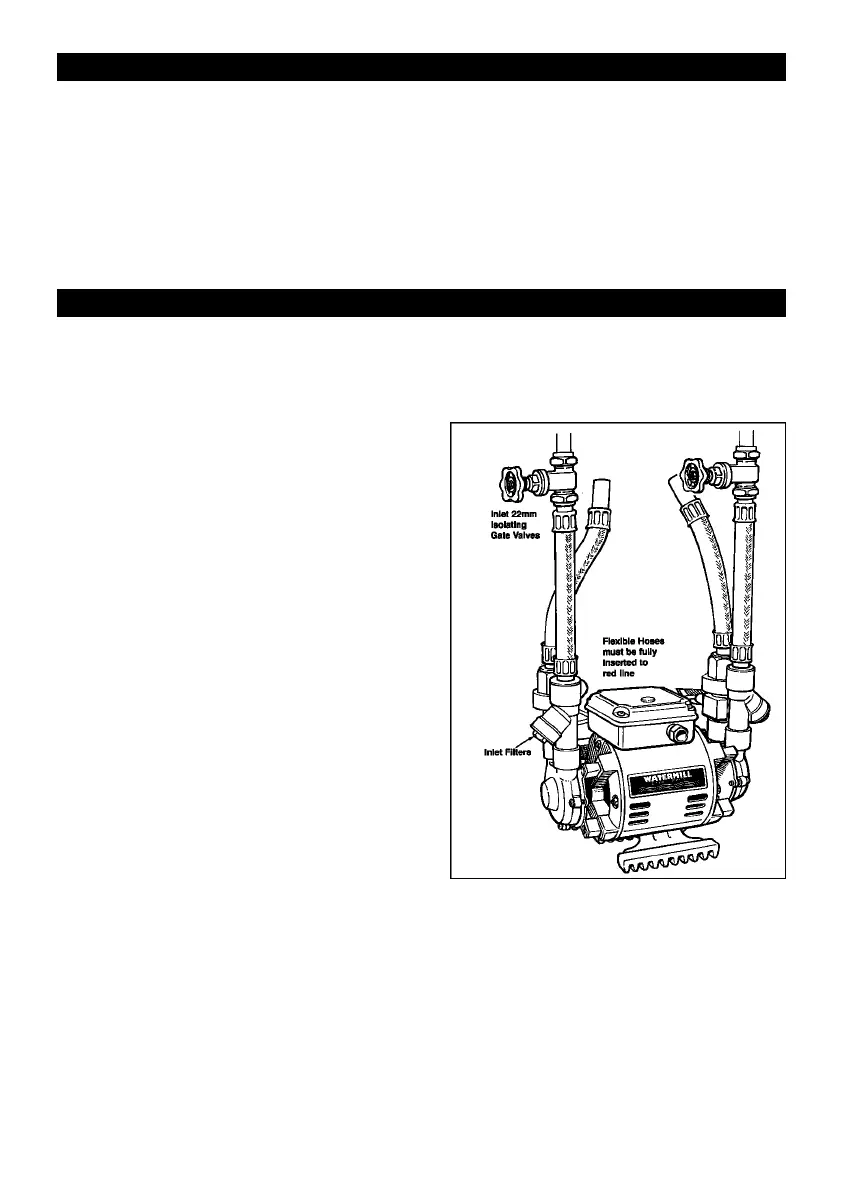

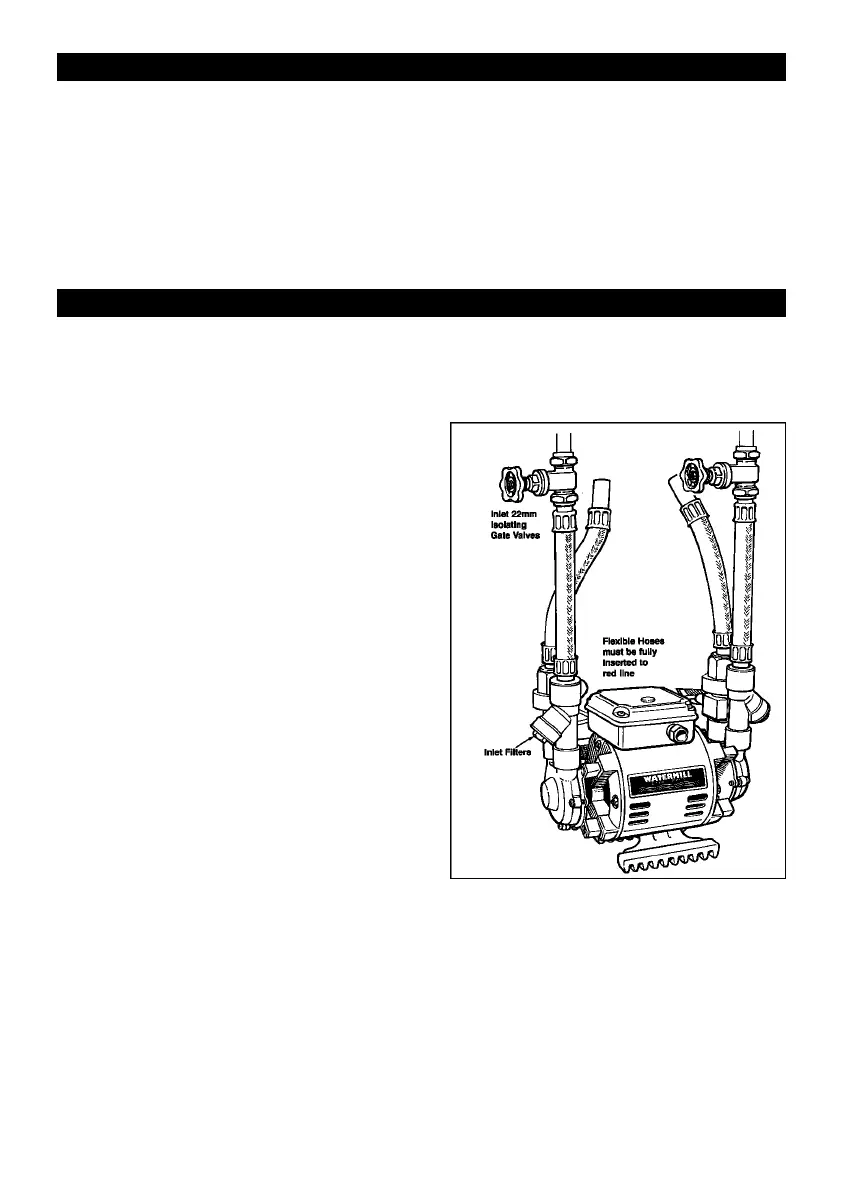

For ease of installation, future servicing and cleaning of filters, full bore isolating gate

valves should be fitted in both hot and cold inlets and outlets.

Isolating valves greatly assist draining down,

filter cleaning and refilling, which will result in

much lower service costs.

The flexible hoses supplied with the pump, or

authorised replacements from Watermill, must

be used for connecting this pump to the

pipework. Use of these hoses will ensure strain

and vibration-free watertight connections.

Make sure each hose connection is fully

inserted to the red “insert guide line”. When

connecting to the pump hoses, make sure

connecting pipe is fully inserted to a minimum

depth of 33mm (1

1

/4”). Failure to fully insert

connections will cause leaks

The inlets to the pump are fitted with strainers

to prevent damage to the pump from abrasive

debris in the water supply.

After initial installation, run the pump for a few

minutes, switch off, drain down and clean the

strainers.

If Y strainers are fitted (as fig. 2) access is via the angled plug on the inlet port. If internal

strainers are used remove the inlet hose from the pump and the strainer basket can be

removed by hand or with long nosed pliers.

Position pump level (see section 3 positioning pump) ensuring that the outlets are vertical

for correct operation of the flow switches.

Line up pipework and fit hoses to pump before connecting to pipes. Position pipework

accurately sop that the pump is not subject to mechanical strain, such as supporting

weight of pipes.

Do not bend hoses as this will cause restriction of flow.

Figure 2

4

Loading...

Loading...