24

LOSES FLAME DURING CYCLE – CONTROL LOCKS OUT ON SAFETY

COMPLETES 30 SECOND PREPURGE CYCLE, AND 8 SECOND SAFE START CHECK.

-FLAME IS ESTABLISHED.

-SOMETIMES THE CONTROL LOCKS OUT BEFORE THE THERMOSTAT OR CONTROLLING CIRCUIT IS SATISFIED.

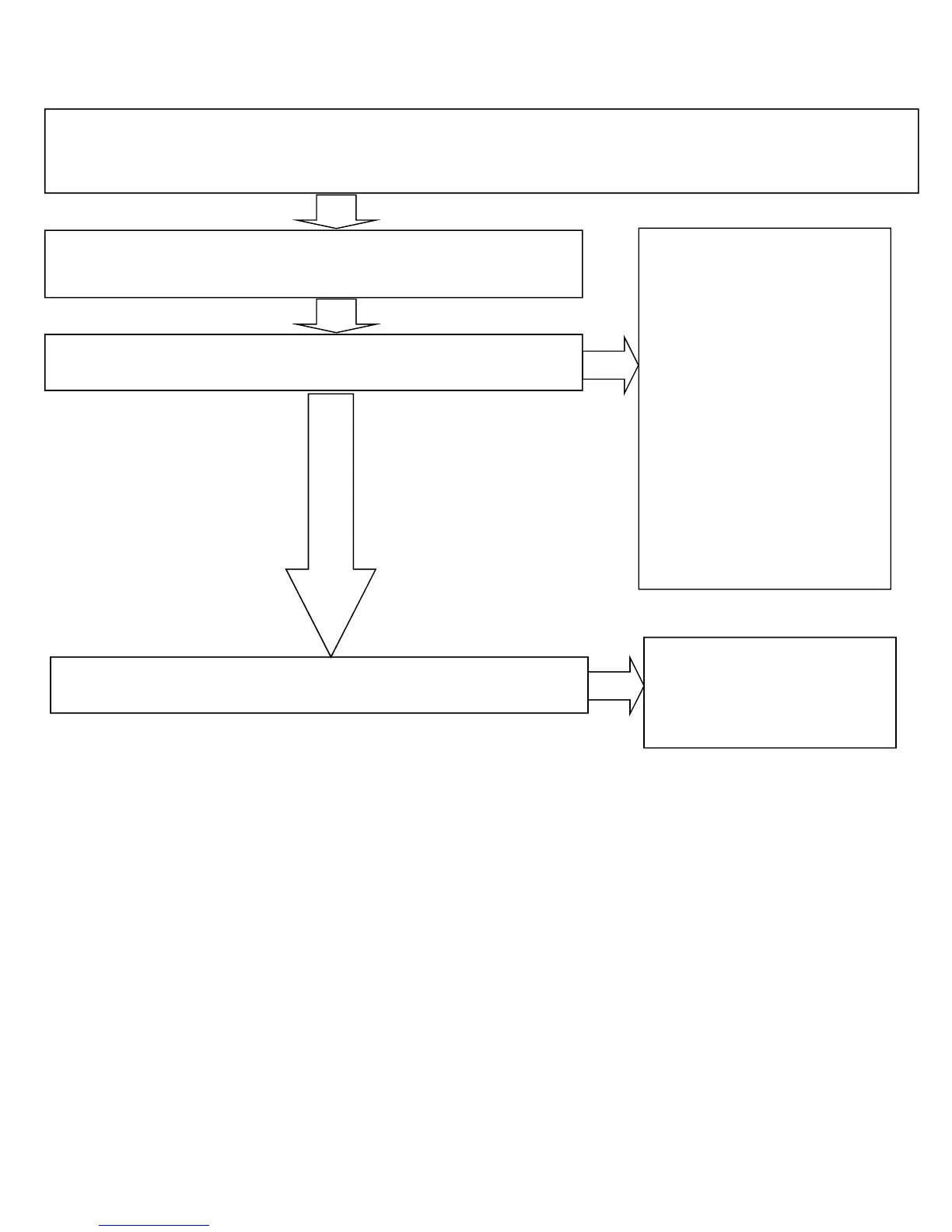

2. DISCONNECT FLAMEROD LEAD FROM PRIMARY CONTROL. CONNECT (+) POSITIVE LEAD (DC) MICROAMPERE

METER TO THE PRIMARY CONTROL TERMINAL. CONNECT THE (-) NEGATIVE MICROAMPERE METER LEAD TO

THE FLAMEROD TERMINAL (SEE FIGURE 9) FLAME CURRENT MEASUREMENT.

2. RESET CONTROL, AFTER PREPURGE CYCLE, FLAME IS ESTABLISHED. A STABLE MICROAMPERE CURRENT OF

.8 OR MORE IS REQUIRED FOR DEPENDABLE OPERATION.

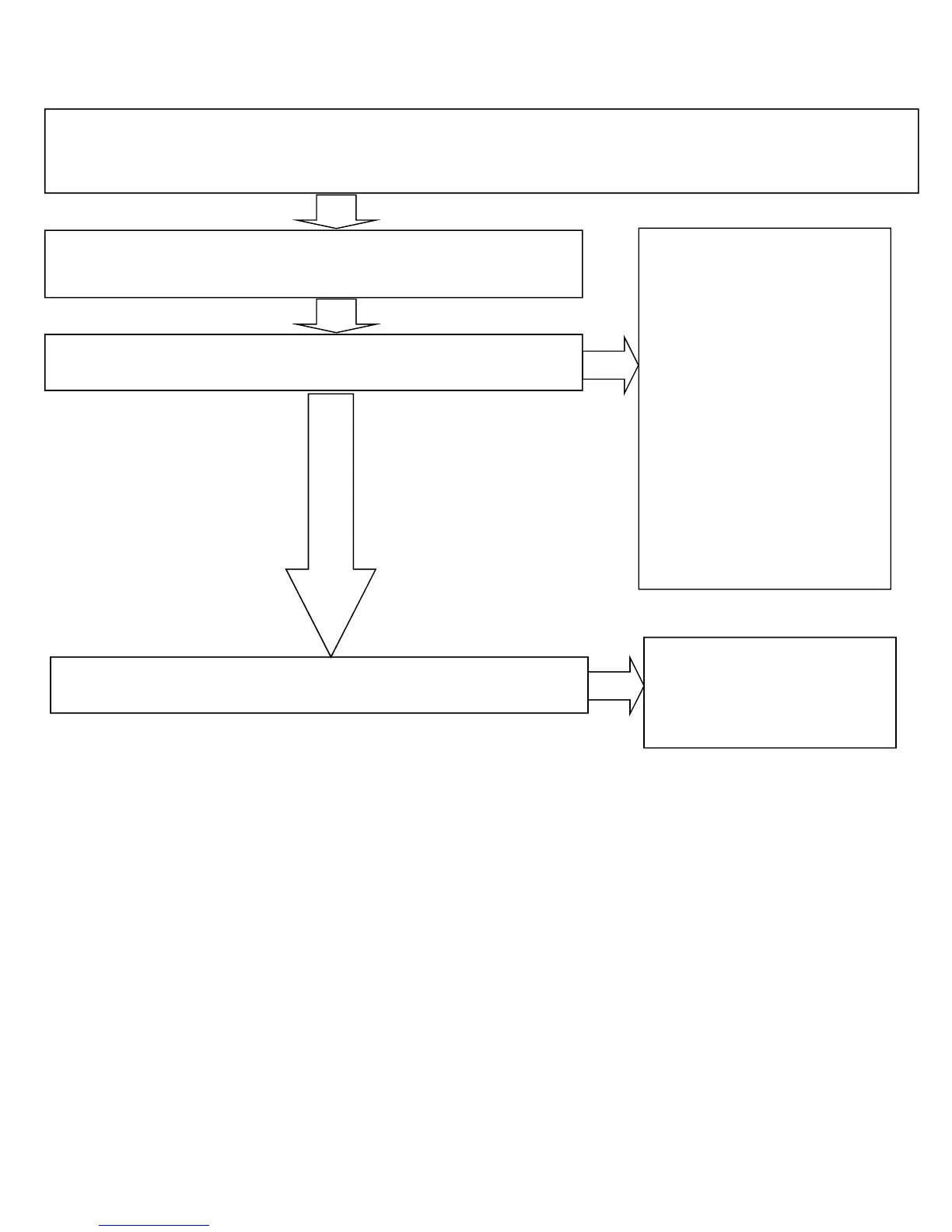

PROBABLE CAUSE OF ERRATIC LOCKOUT:

1. FLAME PROVING CIRCUIT GROUNDED BY

MOISTURE.

2. DAMAGED INSULATION ON FLAMEROD LEAD.

3. FLAMEROD IMPROPERLY POSITIONED IN

FLAME (FIG 1)

4. POOR GROUND PATH TO PRIMARY CONTROL.

5. DEFECTIVE PRIMARY CONTROL.

6. READ MANUAL SECTION “FLAME SENSING”.

7. DEPOSITS ON FLAME ROD. REFER TO

TECHINCAL INFORMATION, PAGE 34.

8. INSURE GROUND ROD AT END OF AIR TUBE IS

IN PLACE. SEE FIGURE 28

9. APPLICABLE TO HONEYWELL S89 SERIES

PRIMARY IGNITION CONTROLS: CONNECT L1 TO

THE BLACK LEAD AND L2 TO THE WHITE LEAD

EXITING THE S89 OTHERWISE THE S89 WILL

NOT DETECT THE FLAME AND LOCK OUT.

4. MICROAMPERE READING IS LESS THAN .8 OR UNSTABLE.

1. EXTREMELY POOR COMBUSTION LEVEL.

2. FLAMEROD IMPROPERLY POSITIONED IN

FLAME.

3. DEFECTIVE PRIMARY CONTROL.

NO

Loading...

Loading...