20

6 Components

6.1.8 Temperature Limiter

and

Safety Switch

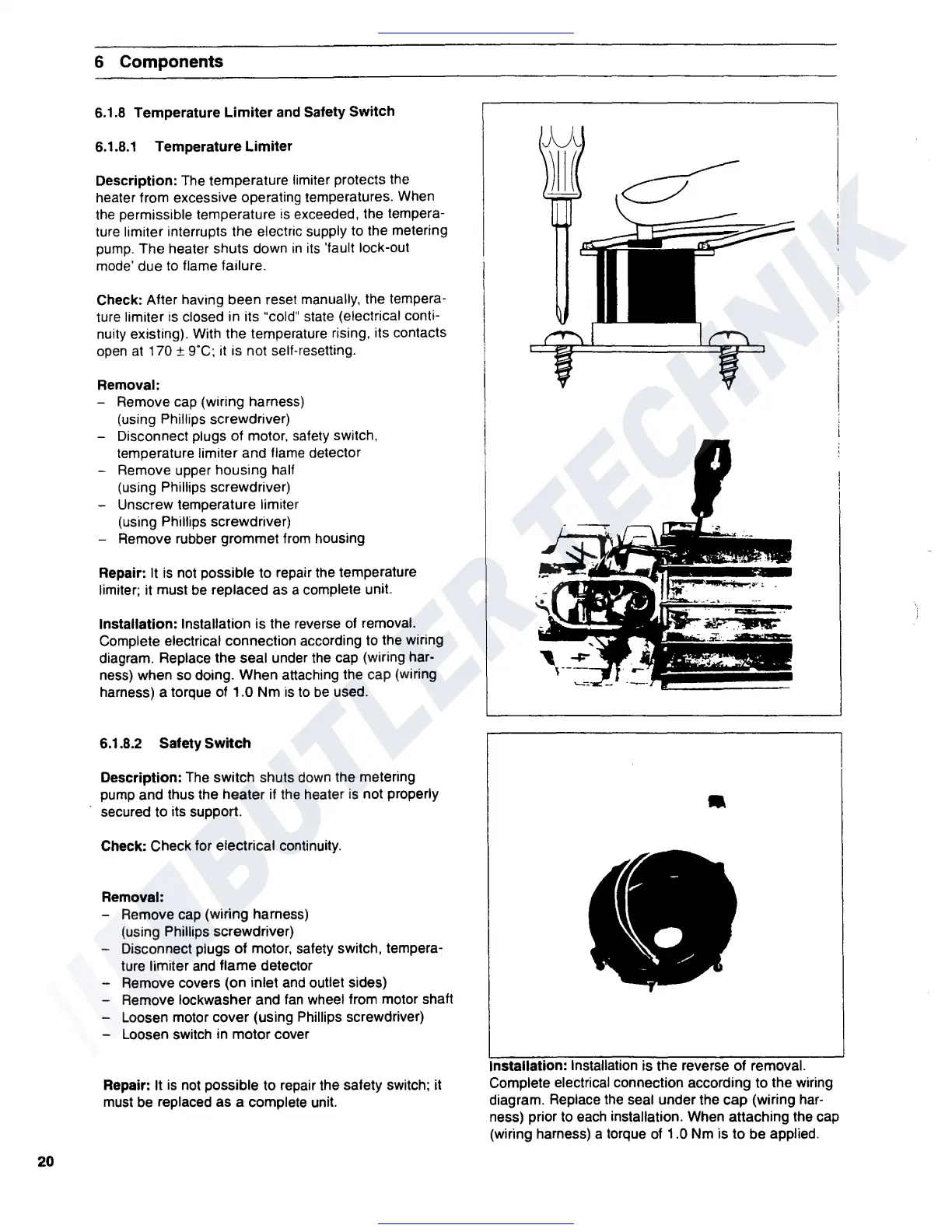

6.1.8.1 Temperature Limiter

Description: The temperature limiter protects the

heater from excessive operating temperatures. When

the

permissible temperature

is

exceeded, the tempera-

ture limiter interrupts the electric supply to the metering

pump. The heater shuts down

in

its

'fault lock-out

mode' due

to

flame failure.

Check: After having been reset manually, the tempera-

ture limiter

is

closed in its "cold" state (electrical conti-

nuity existing). With the temperature rising, its contacts

open

at

170 ±

g·c;

it is not self-resetting.

Removal:

- Remove cap (wiring harness)

(using Phillips screwdriver)

Disconnect plugs of motor. safety switch,

temperature limiter and flame detector

Remove upper housing half

(using Phillips screwdriver)

Unscrew temperature limiter

(using Phillips screwdriver)

Remove rubber grommet from housing

Repair: It

is

not possible to repair the temperature

limiter; it must

be

replaced as a complete unit.

Installation: Installation is the reverse

of

removal.

Complete electrical connection according to the wiring

diagram. Replace the seal under the cap (wiring har-

ness) when

so

doing. When attaching the cap (wiring

harness) a torque

of

1.0 Nm is

to

be

used.

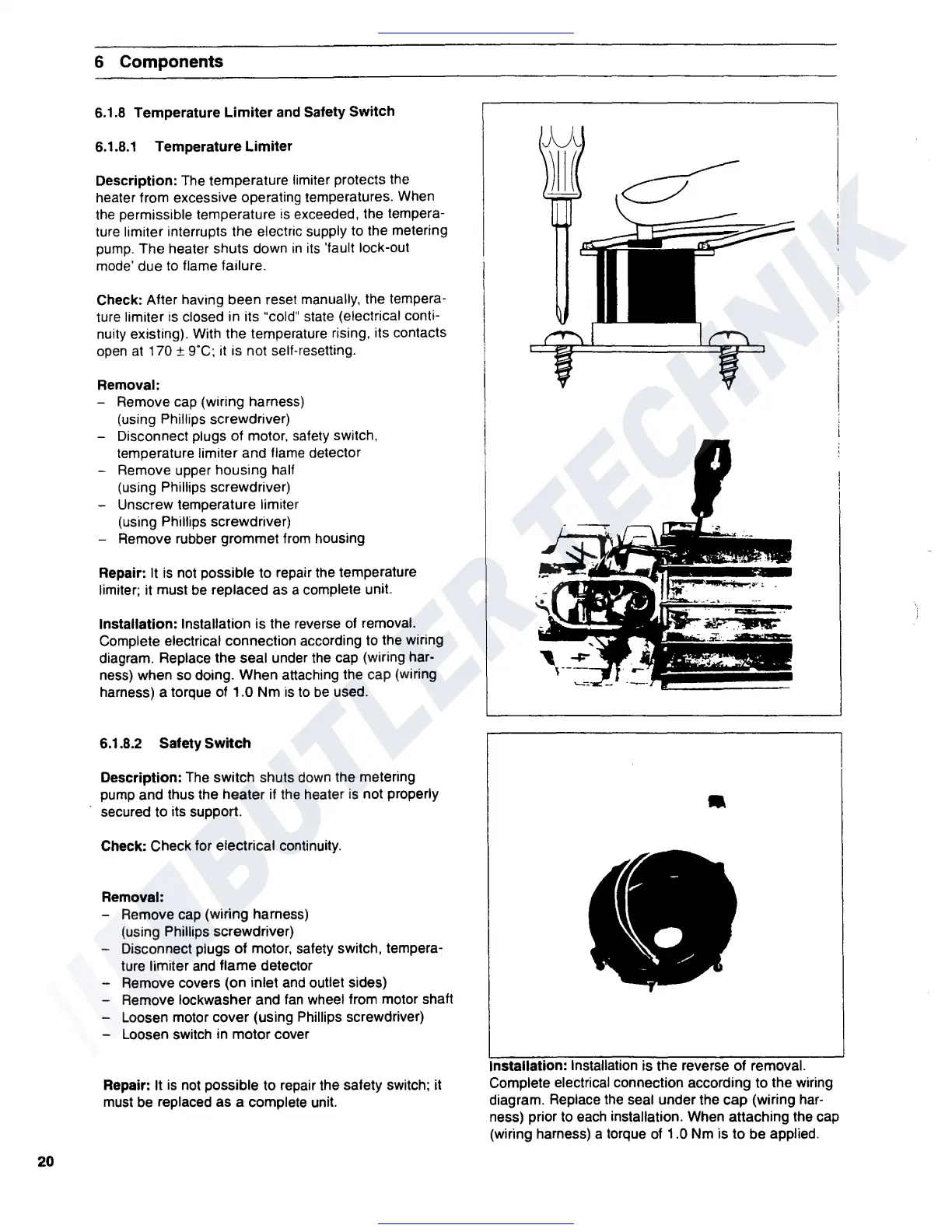

6.1.8.2 Safety Switch

Description: The switch shuts down the metering

pump and thus the heater if the heater

is

not properly

secured to its support.

Check: Check for electrical continuity.

Removal:

- Remove cap (wiring harness)

(using Phillips screwdriver)

- Disconnect plugs

of

motor, safety switch, tempera-

ture limiter

and

flame detector

- Remove covers (on inlet

and

outlet

sides)

- Remove lockwasher and

fan

wheel from motor shaft

- Loosen motor cover (using Phillips screwdriver)

- Loosen switch in motor cover

Repair: It

is

not possible to repair the safety switch; it

must

be

replaced as a complete unit.

•

Installation: Installation is the reverse of removal.

Complete electrical connection according to the wiring

diagram. Replace

the

seal under the

cap

(wiring

har-

ness) prior to each installation. When attaching the cap

(wiring harness) a torque

of

1.0 Nm is to be applied.

Loading...

Loading...