Roof-Mounted Air Conditioner KK2000 E

Page 23 / 30

WARNING

The coolant may never be released into the air (§ 8, CFC

chlorofluorocarbon prohibition from May 06, 1991).

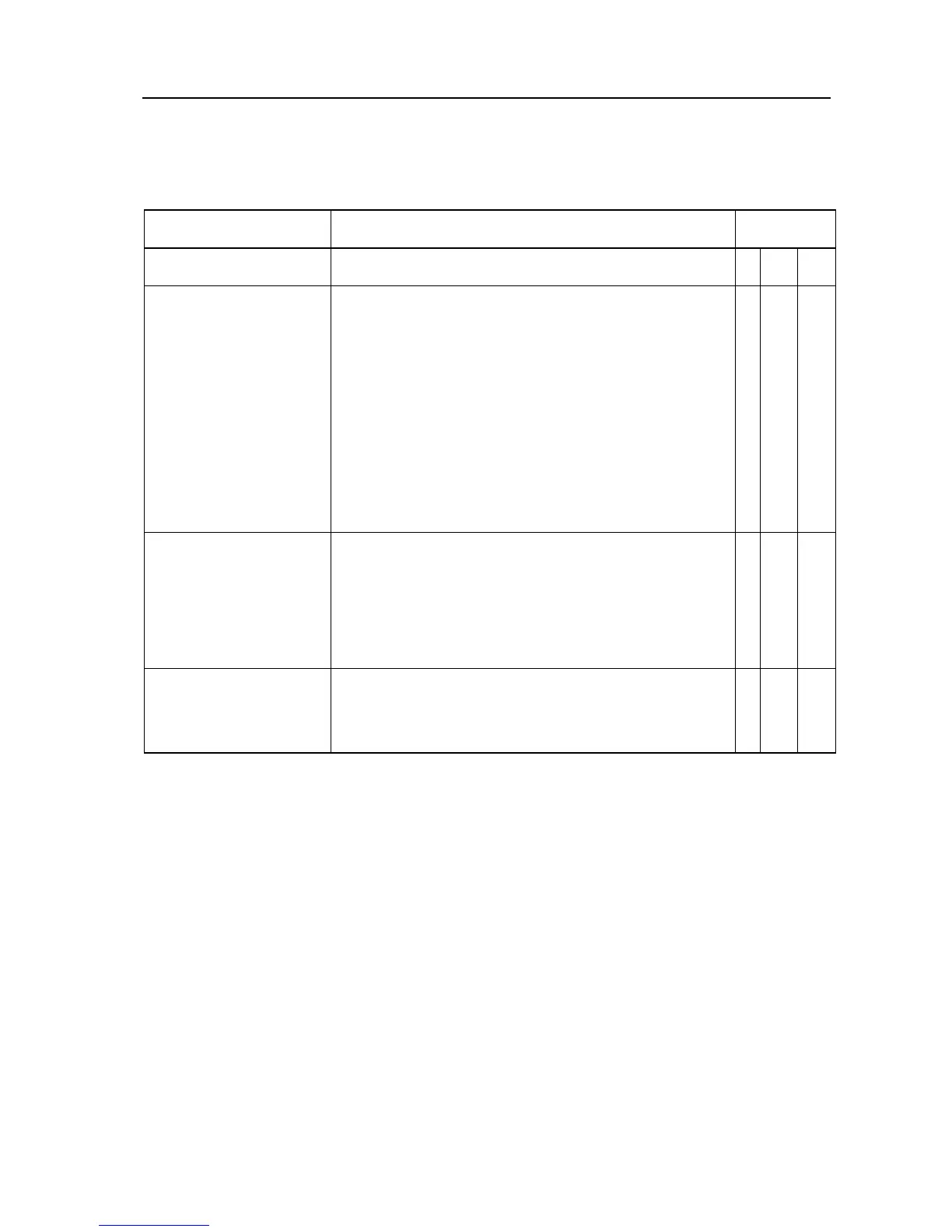

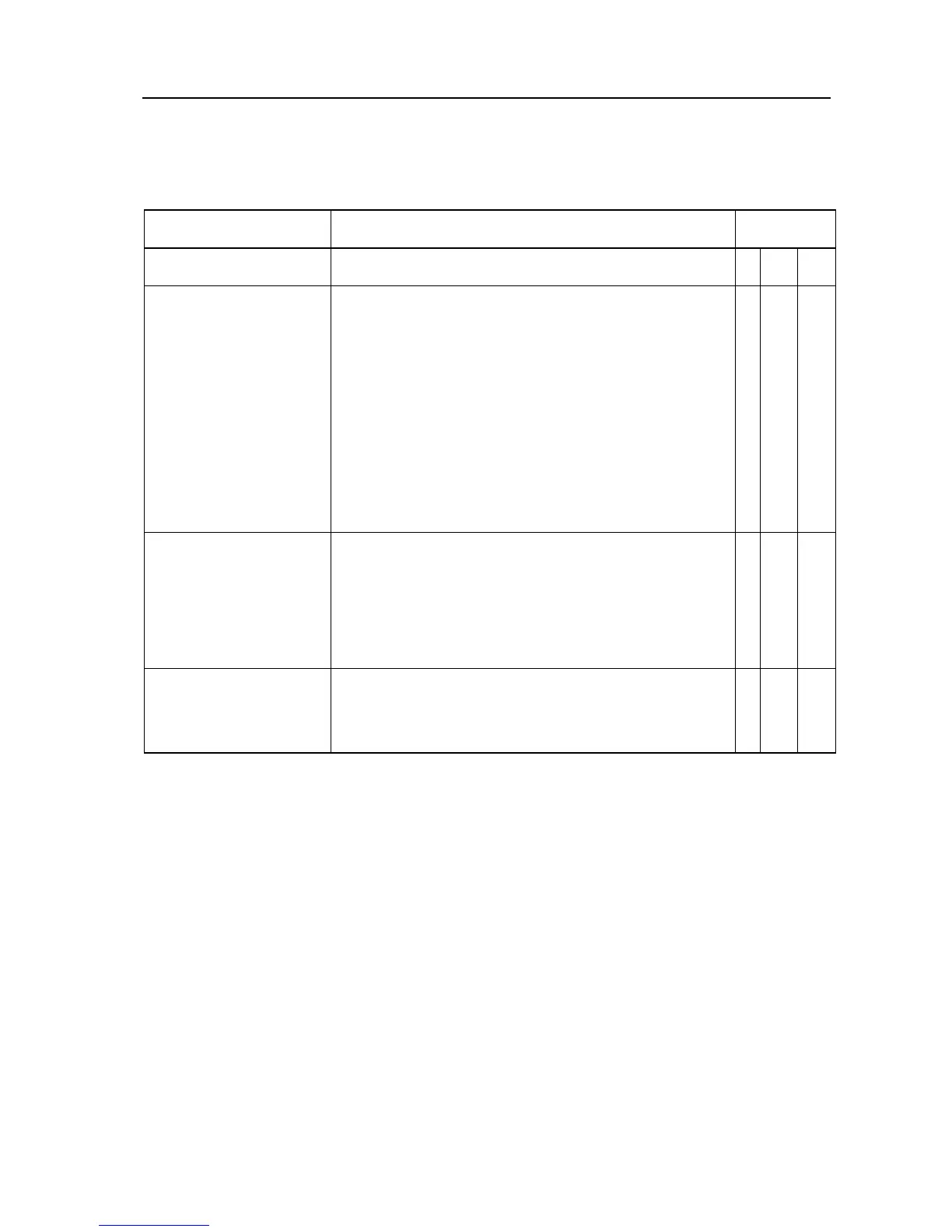

6.4 Checklist for Care and Maintenance

System component Maintenance work Occurrence

m 6m a

Coolant system

– Lines

– Connections

– Coolant level

– Condenser

– Accumulator Dryer

– Condensation water

drainage

– Roof-Mounted Air

Conditioner

Check condition and sealing (leak search device)

Check sealing with leak search device

Check coolant amounts on glass front and pressure

Check condition of blades (clean if dirty)

Replace

Check opening is not clogged and clean if dirty

Check entire condition and connections for tightness.

X

X

X

X

X

X

X

Compressor

– Magnetic coupling

– Compressor

– Fan belts

– Fastening element

Check that the coupling/start of compressor does not slip

Check for noise when running

Check for perfect condition and tension.

Check for condition and tightness.

X

X

X

X

Elect. Connections

– Connection lines

– plug-in connections

Check for perfect condition.

Check for perfect condition and tightness.

X

X

Legend: m – monthly, a – annually (a – if operated all year, perform twice a year)

6.5 Trouble-Shooting and Correction Measures

General

a) Proceed systematically for trouble-shooting and correction. Take the

corresponding steps for general malfunctions or deviations from expected

conditions in the pressure check as described below.

b) Certain problems can only be detected and corrected by trained personnel with

special tools.

c) If there damages to the compressor (for example, defective valve plates), the

expansion valve must be replaced as the possible cause of damage.

Loading...

Loading...