1. Ensure that the area in which the machine will be stored is well-ventilated and free of any potential

fire hazards such as open flames, gas appliances, furnaces, water heaters, and other appliances.

2.Clean and lubricate machine prior to storage.

3.Lightly lubricate flails and rotor to inhibit rusting.

4.Touch-up any scratches or damaged area exposing metal to the elements.

5. Order and re-apply any safety labels. Refer to "Information on Safety Decals" in" Parts

Breakdown Section" of the manual for placement and parts numbers.

6.Verify with engine manufacturer's handbook for guidance on preparing engine for storage.

7.Store unit in transport position (see "Transporting the SCARIFIER " in "Operation Procedures"

section).

8.Store the machine in a covered or indoor storage area for increased protection and longevity.

This section encompasses two general types of maintenance:

1. Preventative Maintenance and 2. General Service. The first refers to regularly scheduled

routine care of the scarifie r, such as cleaning and lubrication. The second provides information

on common procedures, such as changing flails, and adjusting the drive belt that are to be

performed as needed.

By following the Inspection Schedule below BEFORE and AFTER each use of the scarifie r,

appropriate actions can be taken to extend the service life of the machine and reduce any costly repairs

and unnecessary downtime for the unit.

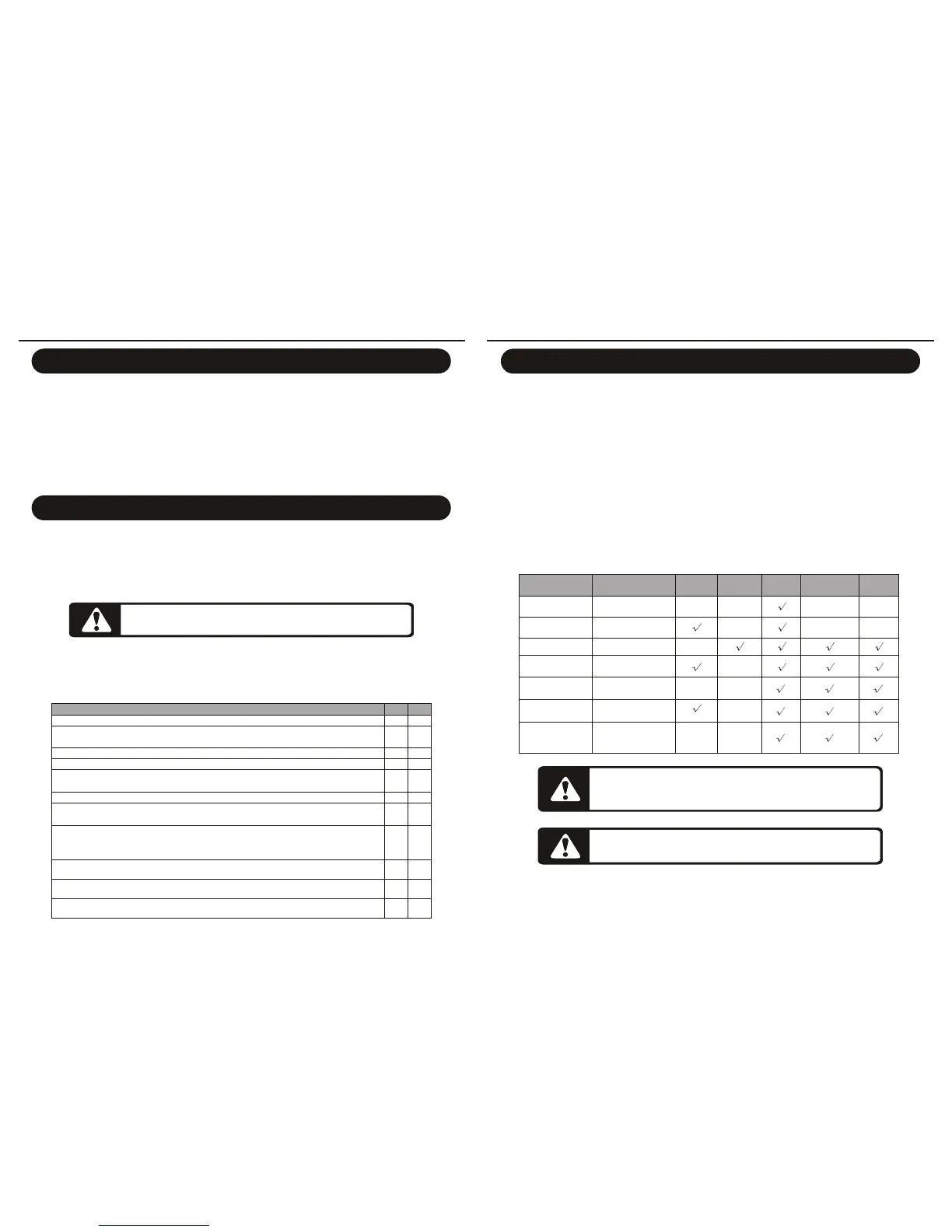

A. Inspection Schedule

The following list aims to offer some basic guidelines to performing a detailed inspection BEFORE and

AFTER each use. Certain checks will require some disassembly, i.e. the removal of the drive guard, to

perform. Depending on various environ-mental conditions and frequency of use, other inspection points may

have to be added for each machine.

B. Preventative Maintenance Procedures

Maintaining a regular cleaning and lubrication schedule as well as taking time to perform preventative

maintenance procedures, will prolong the service life of the SCARIFIER. The following are guidelines to

setting up a regular maintenance routine for the scarifier.

1. Cleaning the SCARIFIER

i. After each use, the scarifier, in particular the flails and rotor assembly, should be cleaned and

washed of any dirt or debris that may be trapped in the unit.

ii. When using a power pressure washer to clean the unit, DO NOT USE ANY MACHINE RATED

HIGHER THAN 1000 PSI.

iii. Beware of damaging any warning decals and labels, as well as the drive belt, bearings and engine.

Limit direct spray on these objects to help prevent their wear and tear.

iv. For easier access to cleaning the scarifier, the machine may be tipped on its engine guard for

NO MORE THAN 2 MINUTES. Engine damage may result from petrol flowing into the crankshaft

due to prolonged tipping.

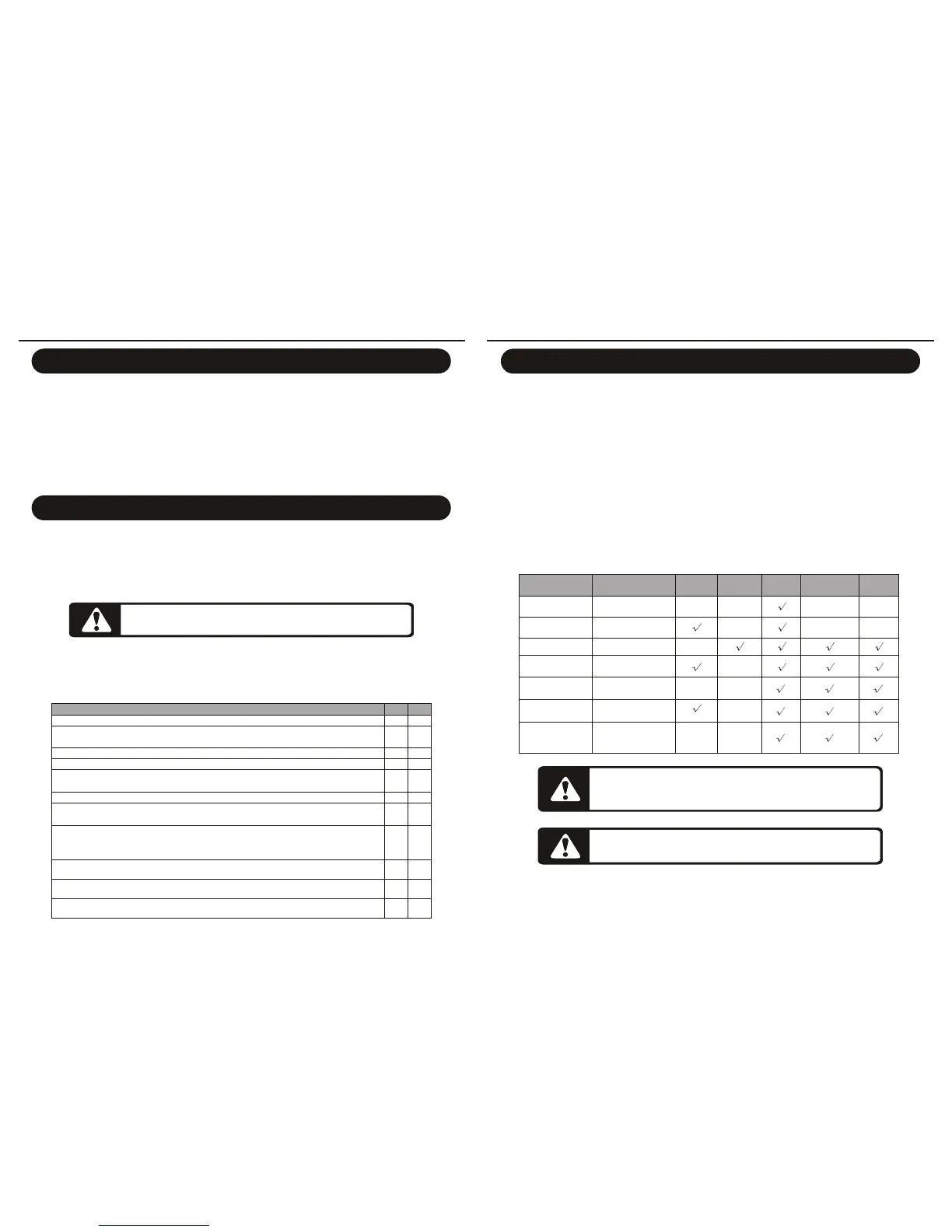

2. Lubrication Schedule

Regularly scheduled lubrication of the wheels, flails & rotor assembly, and linkage joints in the carriage is

essential to smooth performance and extended equipment life. The following schedule is a recommended

guide to lubricating your SCARIFIER. The schedule should be adjusted for various environmental conditions

and frequency of use.

Loading...

Loading...