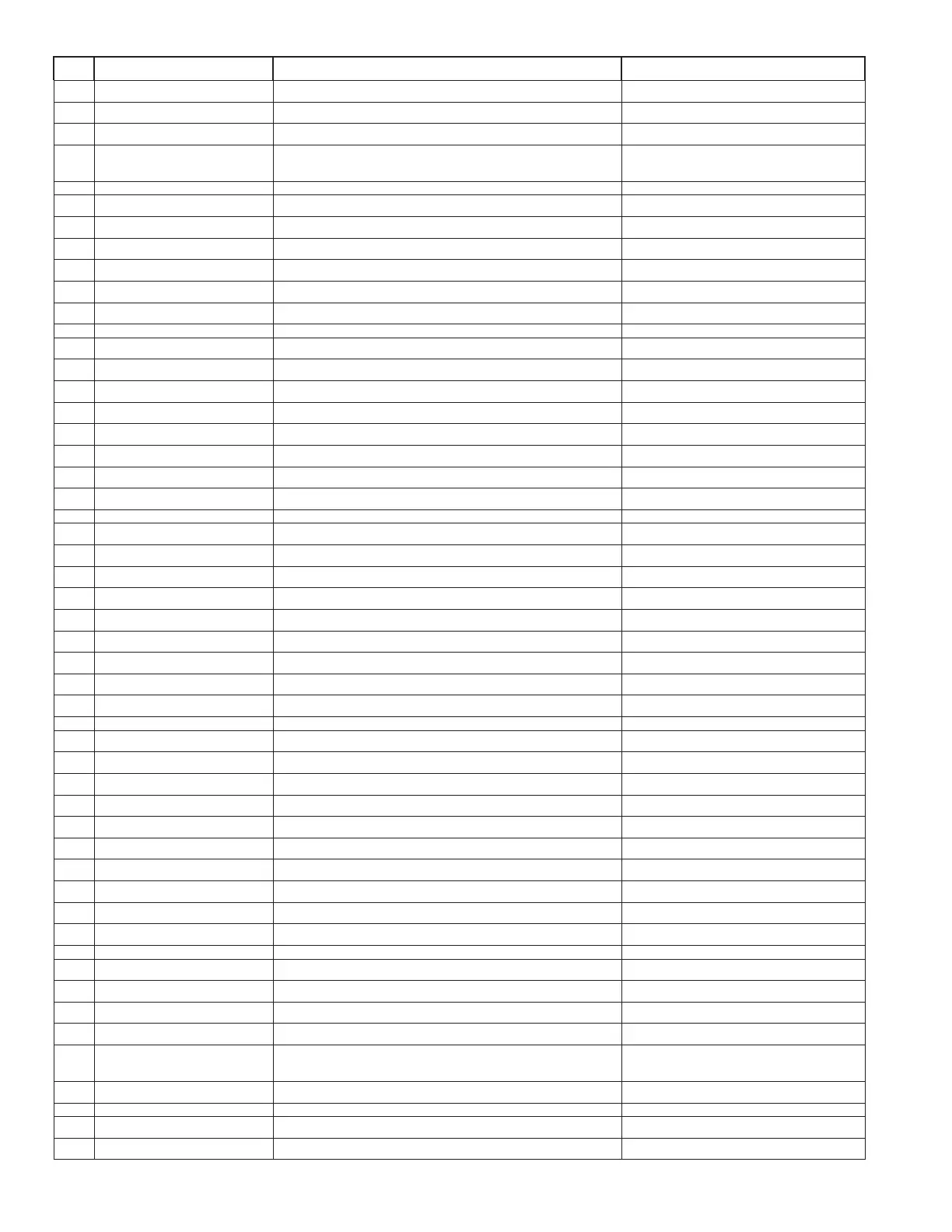

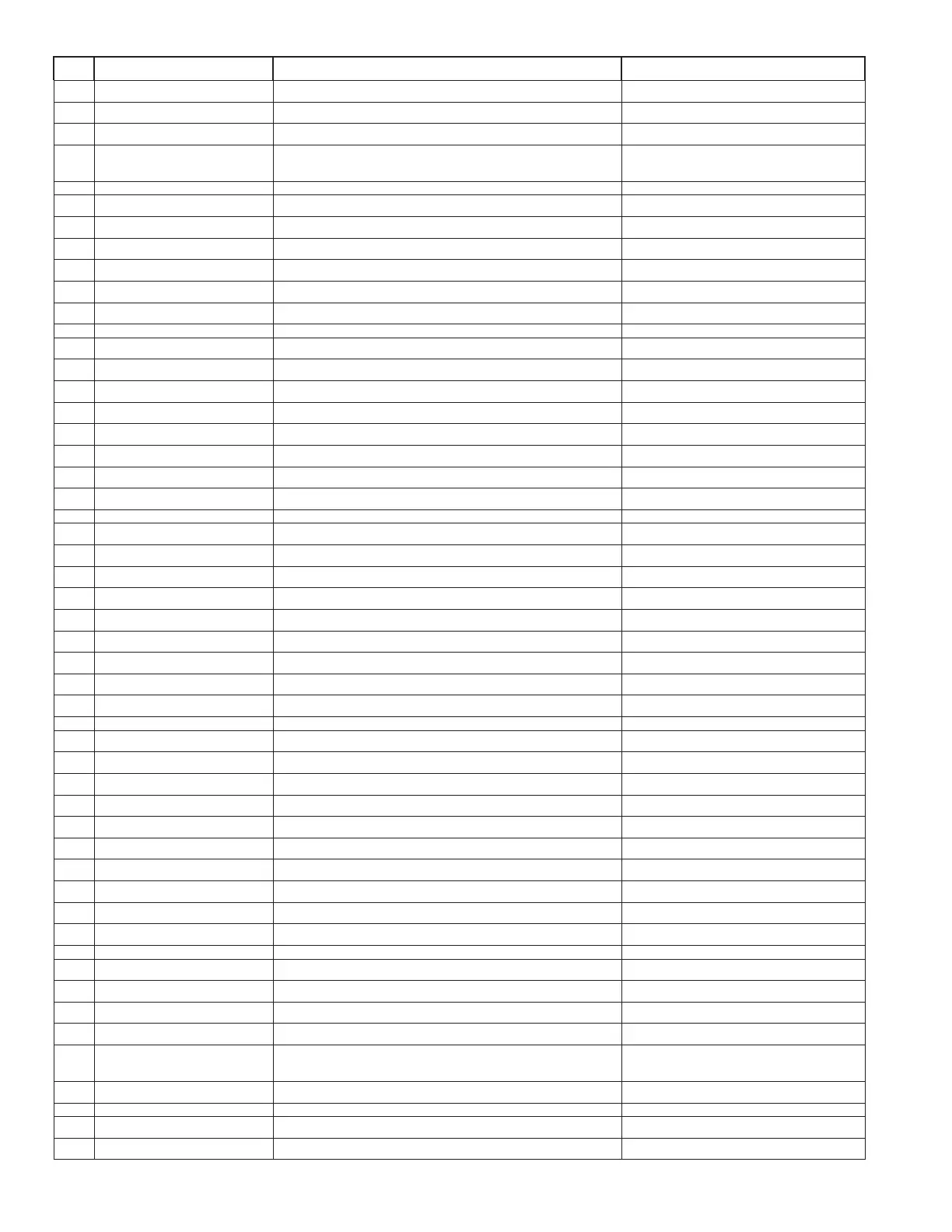

No. System Cause Correction

High CO at low re (con’t) High stack draft (especially at low re) Stabilize draft

(ring gas) Poor air ow distribution (off center ame) Adjust air straightener blade

Diffuser not in optimum position Adjust diffuser position in or out

Fluxuating gas pressure (regulator not holding pressure) Check regulator pressure, sensing line

and supply pressure: sized properly

10 Gas combustion noise Input too low for burner components Check input, compare to rating label

(rumbling) Improper excess air Readjust excess air

Fluxuating gas pressure (regulator not holding pressure) Check regulator pressure and supply

High stack draft (especially at low re) Stabilize draft

Diffuser not in optimum position Adjust diffuser position in or out

Poor air ow distribution (off center ame) Adjust air straightner blade

11 Oil combustion smoking Oil nozzle dirty or plugged Clean oil nozzle

Improper excess air Readjust excess air

Input too low for burner components Check input, compare to rating label

High stack draft (especially at low re) Stabalize draft

Incorrect nozzle position Adjust the nozzle to diffuser position

Fluxuating oil pressures (regulator not holding) Check regulator pressure and oil supply

Poor air ow distribution (off center ame) Adjust air straightner blade

Too much FGR (if equipped) Reduce FGR rate

12 Fuel-Air-Ratios are Linkage exing Realign linkage, straighten rods

not consistent Linkage slip Check linkage and tighten all joints

Fuel cam screws have moved Replace fuel cam

Fuel line plugged Check and clean lines, strainers & lters

Fuel supply pressure changing Check and/or replace pressure regulator

Combustion air temperature changed Retune burner

Draft condition changed Check draft and outlet damper

Plugged or leaky FGR line Clean / repair

Gas control valve - low re stop not set Adjust low re stop

13 Fuel-Air-Ratios have changed Linkage wear Check linkage and tighten all joints

over time Fuel cam screws have moved Replace fuel cam

Air damper seal worn Replace air damper seals

Fuel lines plugged Check and clean lines, strainers & lters

Fuel control valve worn Replace fuel control valve

Gas orices or gas manifold plugged Clean and/or replace

Combustion air temperature changed Retune burner

Draft condition changed Check draft and outlet damper

Vessel plugged Clean vessel

Plugged or leaky FGR valve Clean / repair

14 Cannot obtain capacity on Wrong spring range in regulator Install higher spring range

gas Too many elbows before control valve Rework piping to reduce elbows

Gas line too small, high pressure drop Use larger pipe size

Supply pressure lower then stated Increase supply pressure

Supply pressure drops too low at high re Use larger gas line sizes / orice in

service regulator

Regulator too small for ow and pressure Change regulator

15 Cannot obtain rated input on Oil nozzles plugged Replace nozzles

oil ring (pressure atomized) By-pass seal on nozzle leaking Replace nozzles

Page 54

JBE(X) Manual Section H - Troubleshooting

Loading...

Loading...