www.weg.net

48 l Installation, operation and maintenance manual – Squirrel cage motor – M line – Vertical 11371757

8 MOTOR DISASSEMBLY AND ASSEMBLY

All the repair, disassembly and assembly services must be performed

only by properly qualified and trained

professionals; otherwise, equipment damage and personal injury may occur. If any further explanations are

necessary, consult WEG.

The disassembly and assembly sequence

s depend on the motor model.

Always use proper tools and devices.

Any damaged part (cracks, dents on machined parts, faulty threads)

must be replaced, avoiding restorations.

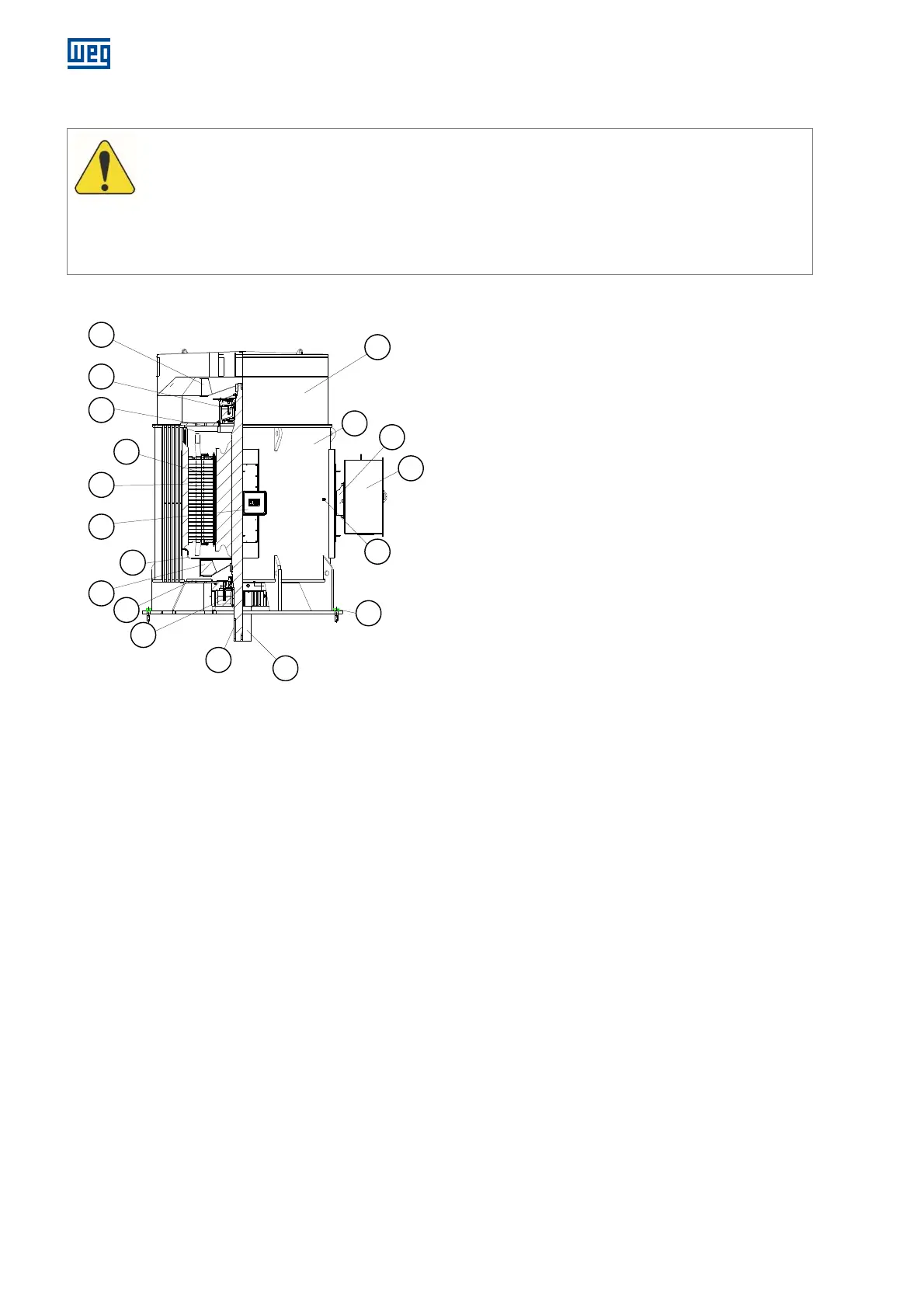

8.1 PARTS LIST

Figure 8.1: Overview of a typical motor with solid shaft and oil-

lubricated rolling bearings

Figure 8.1 legend:

1. Frame

2. Stator

3. Rotor

4. Internal fan

5. External fan

6. Fan cover

7. Grounding terminal

8. Shaft

9. D-end shield

10. ND-end shield

11. DE bearing

12. NDE bearing

13. Key

14. Terminal box support

15. Accessory terminal box

16. Stator terminal box

17. Ventilation box

18. Fastening bolts

8.2 DISASSEMBLY

The following precautions must be taken when

disassembling the motor:

1. Before disassembling the motor, disconnect the water

cooling and lubrication pipes (if any);

2. Disconnect the motor electrical connections and those

of the accessories;

3. Remove the heat exchanger and the noise suppressor

(if any);

4. Remove the bearing temperature sensors and the

grounding brush;

5. In order to prevent damages to the rotor, provide a

support for the shaft on both drive and non-drive ends;

6. In order to disassemble the bearings, follow the

procedures described in this manual, according to the

bearing type;

7. Use a proper device to remove the rotor from the

motor, taking extreme care not to drag the rotor

against the stator laminated core or coil heads, thus

preventing damages.

8.3 ASSEMBLY

In order to assemble the motor, follow the disassembly

procedures in the reverse order.

8.4 AIR-GAP MEASUREMENT

After disassembling and assembling the motor, it is

necessary to measure the air gap in order to check the

concentricity between rotor and stator.

The difference between the air-gap measured in two

points diametrically opposed must be less than 10% of

the average air gap.

16

8

13

7

18

17

1

14

10

2

15

12

5

3

6

11

9

4

Loading...

Loading...