www.weg.net

11371757 Installation, operation and maintenance manual – Squirrel cage motor – M line – Vertical l 49

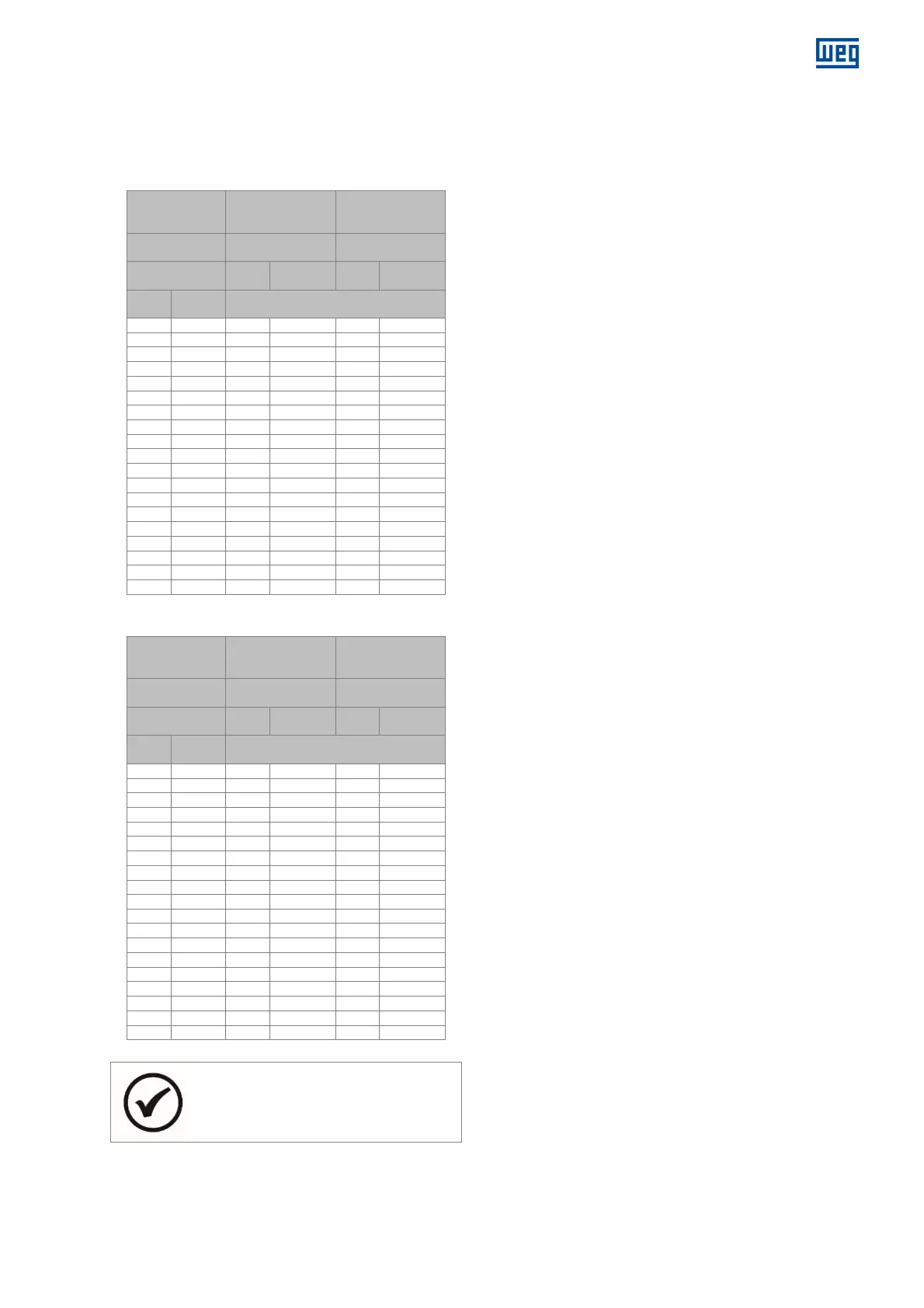

8.5 TIGHTENING TORQUE

The Table 8.1 and Table 8.2 shows the tightening torques

of the screws recommended for assembling the motor.

Table 8.1: Screw tightening torque for metal/metal parts

Resistance

class

Carbon Steel /

8.8 or above

Stainless steel /

A2 – 70 or above

Strength

60%

70%

Lubricant Dry

1000

Dry

1000

Diam

(mm)

Screws tightening torque (Nm)

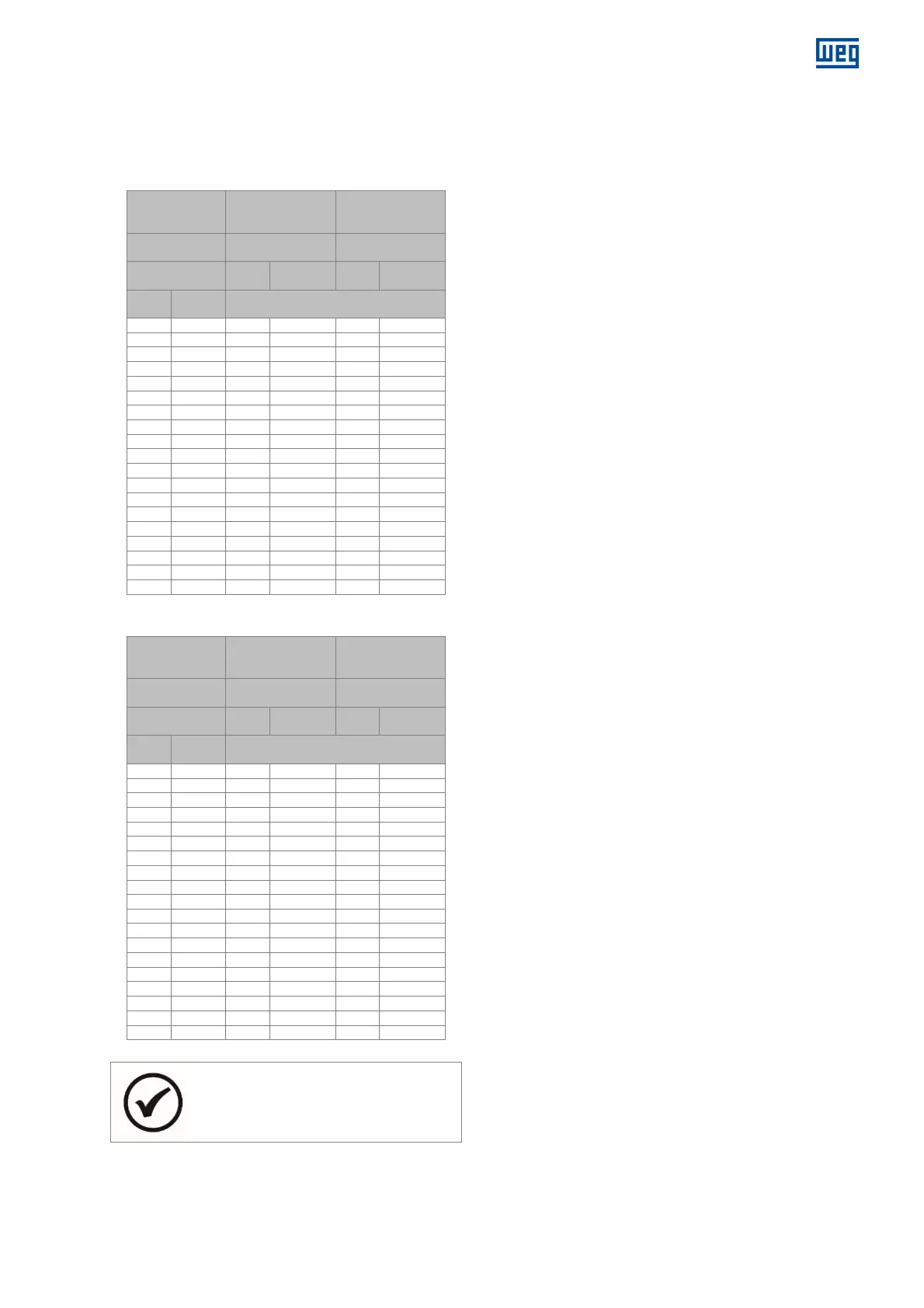

Table 8.2: Screw tightening torque for metal/isolated parts

Resistance

class

Carbon Steel /

8.8 or above

Stainless steel /

A2 – 70 or above

Strength

33%

33%

Lubricant Dry

1000

Dry

1000

Diam

(mm)

Screws tightening torque (Nm)

NOTE

The resistance class is normally indicated

on

the head of the hex bolts.

Loading...

Loading...