www.weg.net

11371757 Installation, operation and maintenance manual – Squirrel cage motor – M line – Vertical l 19

3.3.3.11

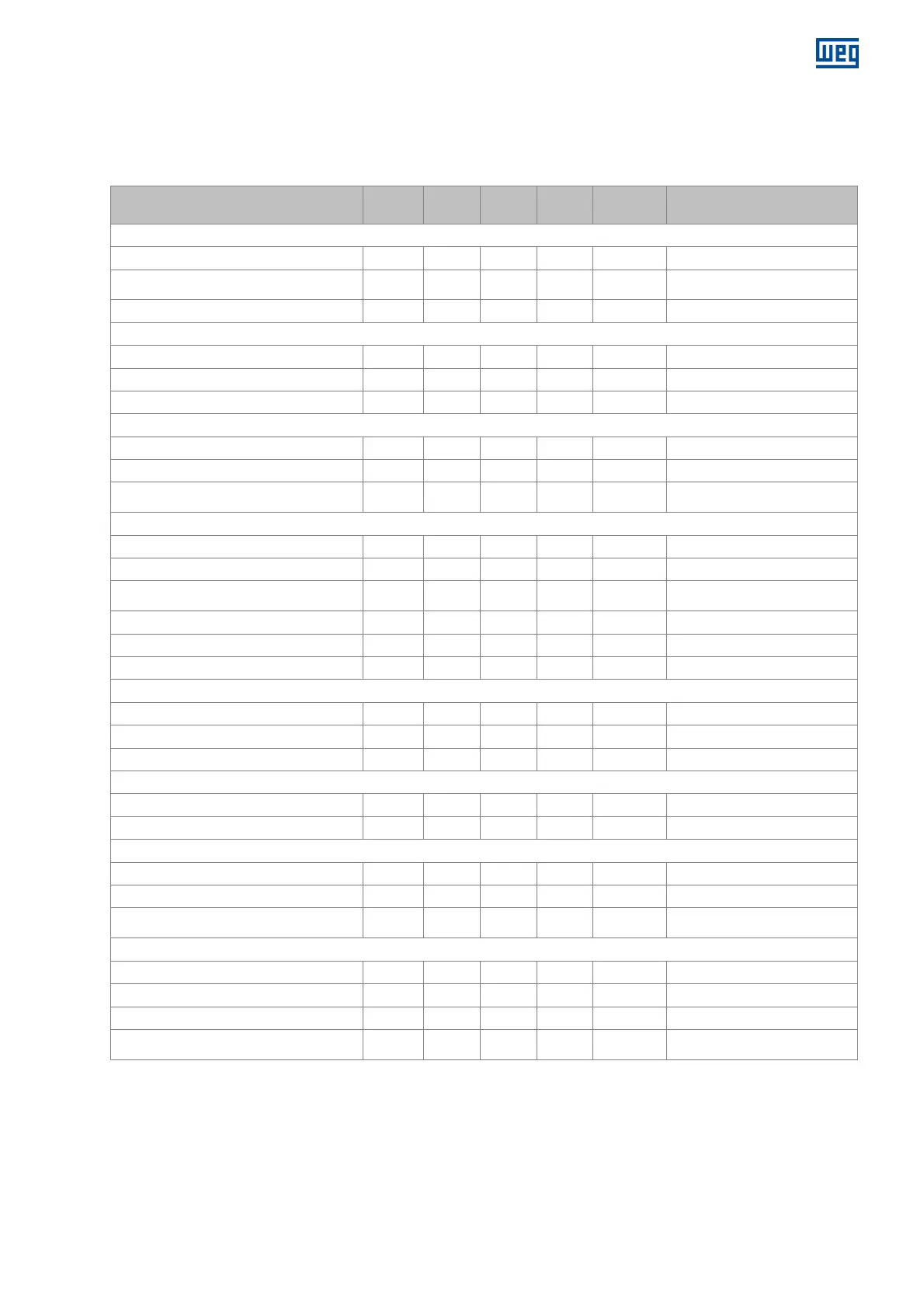

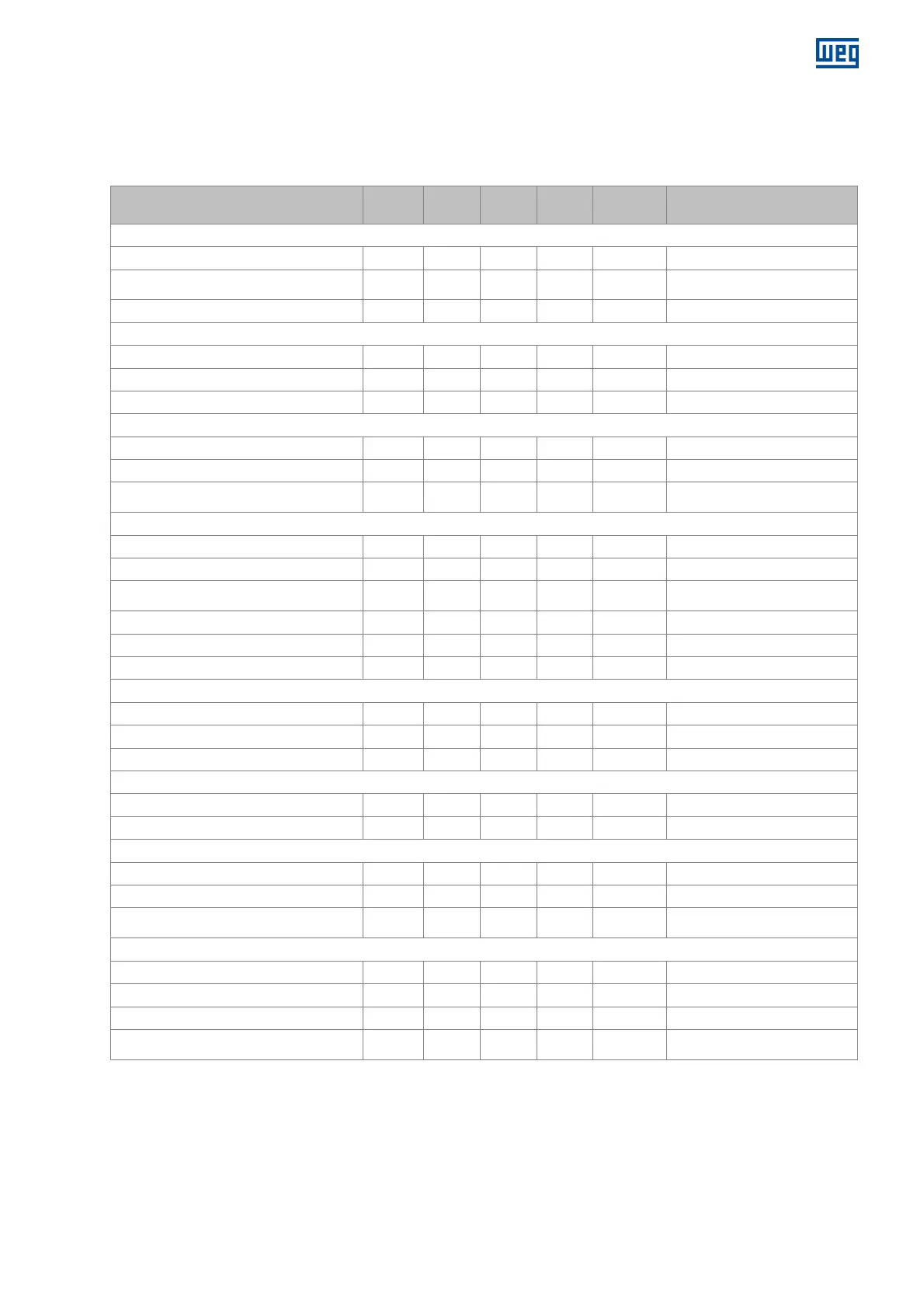

Maintenance plan during storage

During the storage period, the motor maintenance must be performed and recorded according to the plan described in

Table 3.1.

Table 3.1: Storage plan

Monthly

2

months

6

months

2

years

Before

start-up

Notes

STORAGE LOCATION

Inspect the cleanliness conditions

X

X

Inspect the humidity and temperature

conditions

X

Inspect for insect infestation signs

X

PACKAGE

Inspect for damage

X

Check the internal relative humidity

X

Replace the desiccant in the package (if any)

X

Whenever necessary.

SPACE HEATER

Check the operating conditions

X

Measure the circuit voltage and frequency

X

function of the signal system (if

any)

X

WHOLE MOTOR

Perform external cleaning

X

X

Check the painting conditions

X

machined parts

X

Reapply the rust inhibitor

X

Inspect the rubber seals and gaskets

X

Complete predictive maintenance

According to section 3.3.3.10

WINDINGS

Measure the winding temperature

X

X

Measure the insulation resistance

X

X

Measure the polarization index

X

X

TERMINAL BOX AND GROUNDING TERMINALS

Clean the interior of the terminal boxes

X

X

Inspect the seals and gaskets

X

X

ROLLING BEARINGS

Rotate the shaft

X

Relubricate the bearing

X

Disassemble and clean the bearing

years.

SLEEVE BEARINGS

Rotate the shaft

X

Apply corrosion inhibitor spray

X

Clean the bearings

X

Change the oil

If the storage period exceeds 2

years.

Loading...

Loading...