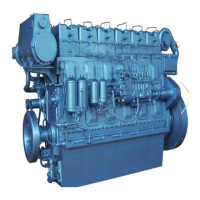

R660系列柴油机维修保养手册

-0-

Maintenace Manual For R660 Series Diesel Engine

检查水泵水封装置,及时研修或更换新件。

Check the water sealing of water pump. Repair or replace if necessory;

检查电起动机的起动电机齿轮磨损情况及其工作是否灵活。

Check the wear and working condition of motor gear of electric starter;

清洗机油、燃油系统管路,清除污物并应吹干净。

Clean oil and fuel pipeline, remove the dirt and clean by blowing.

三级技术保养

Level 3 Technical Maintenance

除二级技术保养项目外再加下列工作:

In addition to Level 2 maintenance,

检查活塞顶部积碳情况,必要时进行清理。检查活塞环、气缸套、连杆小头衬套及连杆轴瓦的

磨损情况,必要时更换。

Check the carbon deposit on the top of piston, cleaning if necessory. Check the wear of piston ring,

cylinder liner, connecting rod small end bushing and connecting rod bearing, replace if necessory;

检查喷油泵内出油阀的密封情况,必要时进行研修或更换。

Check the sealing of outlet valve if injection pump, repair or replace if necessory;

检查喷油器针阀偶件的工作性能,必要时换新。

Check the working performance of needle valve and seat of injector, replace if necessory;

清洗冷却系统内水垢。

Clean the cooling system, remove the scale in it;

根据运行情况,适当调整调速弹簧

Adjust the governing spring properly according to the operation conditions;

检查涡轮增压器中叶轮与壳体的间隙,喷嘴环表面烧损情况及其封、油封零件损坏的情况,必

要时修理或更换。

Check the clearance between the impeller and the casing of turbocharger, the surface ablating of injector

ring and the damaging of oil sealing parts; repair or replace if necessory;

检查机油泵工作情况,必要时进行调整。

Check the working of oil pump, adjusting if necessory;

放净起动空气瓶中压缩空气后,旋开底部的放污螺塞,放出瓶内积水及污物。

After release the air in the starting air bottle, screw off the drainage screw plug at the bottom of the bottle,

discharge the water and dirt.

Loading...

Loading...