--

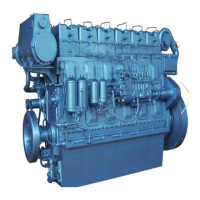

R660系列柴油机维修保养手册

Maintenace Manual For R660 Series Diesel Engine

更换机油,清洗机油滤清器、滤网、机座。

Check the tension of belt, adjusting if necessory;

检查三角皮带的张紧程度,必要时进行调整。

Check intake/outlet valve clearance and advance angle, readjusting if necessory;

检查进、排气门间隙,及喷油提前角,不合规定时,进行调整。

Clean air filter;

清洗空气滤清器。

Check compressor impeller of turbocharger, the inner cavity of compressor casing, turbine and

清洗增压器压气机叶轮,压气机壳内腔,涡轮及涡轮壳等零件的油污和积碳。

turbine housing for oil dirty and carbon deposit;

清洗冷却水散热器中的沉淀物质。

Clean the radiator.

二级技术保养

Level 2 Technical Maintenance

除一级技术保养项目外另添下列工作:

In addition to Level 1 maintenance,

检查各缸工作的平衡性,如条件具备,必要时可调整喷油泵各缸喷油量的均匀性。

Check the balance of cylinders, adjust the balance of fuel injections of all injection pump cylinders if

necessory;

拆下各缸盖,清除燃烧室积碳,检查进、排气门及充气阀阀面以及气门锁夹、推杆和摇臂的配

合面的磨损情况,不合要求时,应进行研修。

Dismantle the cylinder heads, remove the carbon deposit in the combustion chamber. Check the wear

conditions of inlet/outlet valves and valve faces, valve collets, the contact faces of push rod and rocker

arm. Repair if necessory;

检查喷油器的喷油压力和喷雾情况,必要时进行调整和修理。

Check the injection pressure and spraying of injector. Adjusting and repair if necessory;

全面检查各油、水、气和电路件以及各紧固件的连接和紧固情况。

Check the connections of oil, water, gas pipelines and electrical parts and tightening parts;

检查柴油机与其配套工作机械的中心对正情况,并及时调整。

Check the center aligning of the engine and matched machinery. Adjusting if necessory;

检查连杆螺母和飞轮紧固螺母有无松动,不合规定时,应按规定扭紧力矩旋紧。

Check the connecting rod nuts and flywheel tightening nuts for loosing. Tightening according to specified

torque if necessory;

Loading...

Loading...