--

R660系列柴油机维修保养手册

Maintenace Manual For R660 Series Diesel Engine

清理增压器

Clean the turbocharger

清洗增压器压气机叶轮,压气机壳内腔,涡轮及涡轮壳等零件的油污和积碳。

Clean out the oil dust and the carbon deposit on the impeller of compressor, the inner cavity of

compressor casing, the turbine and turbine scroll.

增压器的拆装请参见本手册第八章第 4 小节。

Disassemble/assemble the turbocharger according to section 4 of chapter 8 in this manual.

增压器的维护请参见增压器使用说明书

For maintenance of the turbocharger, please refer to the Operation Manual of Turbocharger.

清洗冷却水水散热器

Clean the cooling water radiator

陆用闭式水冷却循环,采用水散热器冷却柴油机内冷却水,应适时清洗散热器,以保证其散

热效果。

For land engine cooled through close circulating water, the water inside the engine is cooled through

water radiator. So the radiator should be cleaned timely to ensure the cooling effect.

4.柴油机累计运行 1000 小时的保养内容

Maintenance of engine after 1000-hour’s operation

当柴油机累计运行 1000 小时时,除完成一级技术保养,再增加以下项目

In addition to the Maintenance 1, this maintenance also includes:

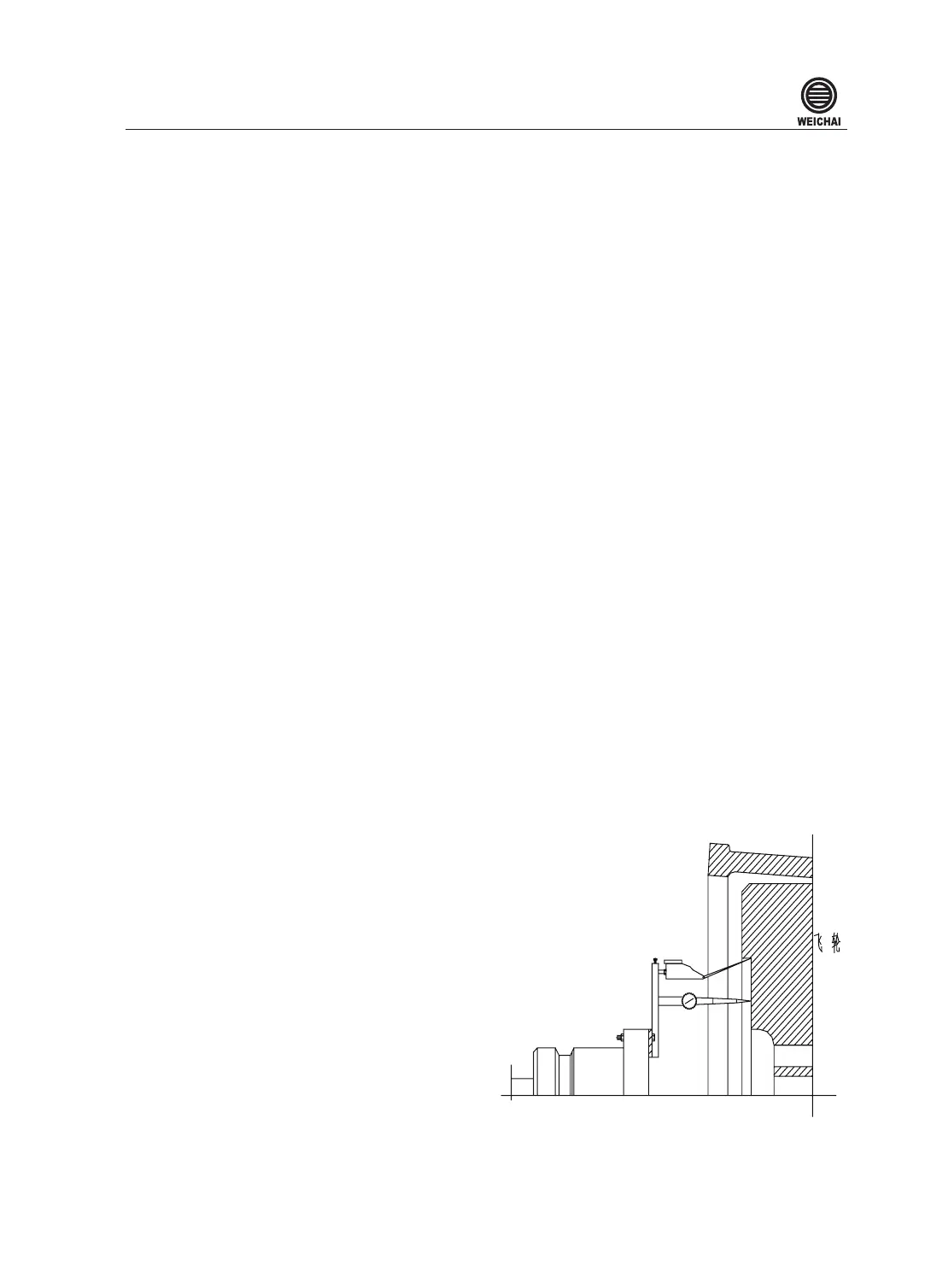

检查柴油机的对中

Check the alignment of diesel engine

检查对中时要用百分表测量柴油机

和被驱动设备的同轴度和端面跳动。如

果是弹性连接,其同轴度和端面跳动均

应小于 0.2mm,若是刚性连接,其同轴度

应小于 φ0.08mm,若是测量结果超出了

上述规定,用不同厚度的钢片进行调整。

The end face run-out and axiality of the

diesel engine and the driven equipment

should be measured by centigrade meter.

For flexible connection, the axiality and end

face run-out should be less than 0.2mm,

for rigid connection, the axiality should be

less than φ0.08mm; If the measurements

were beyond above-mentioned range, the

steel disc with different thickness is used to

adjust.

Loading...

Loading...