11

• Set the spool brake tensioner by tightening or loosening the wire spool retaining nut.

Set the spool brake tension so that the spool can rotate freely, without continuing to rotate once the wire feed stops.

Check performance from time to time to ensure that the wire is feeding correctly, especially as the wire spool empties.

WIRE FEEDER

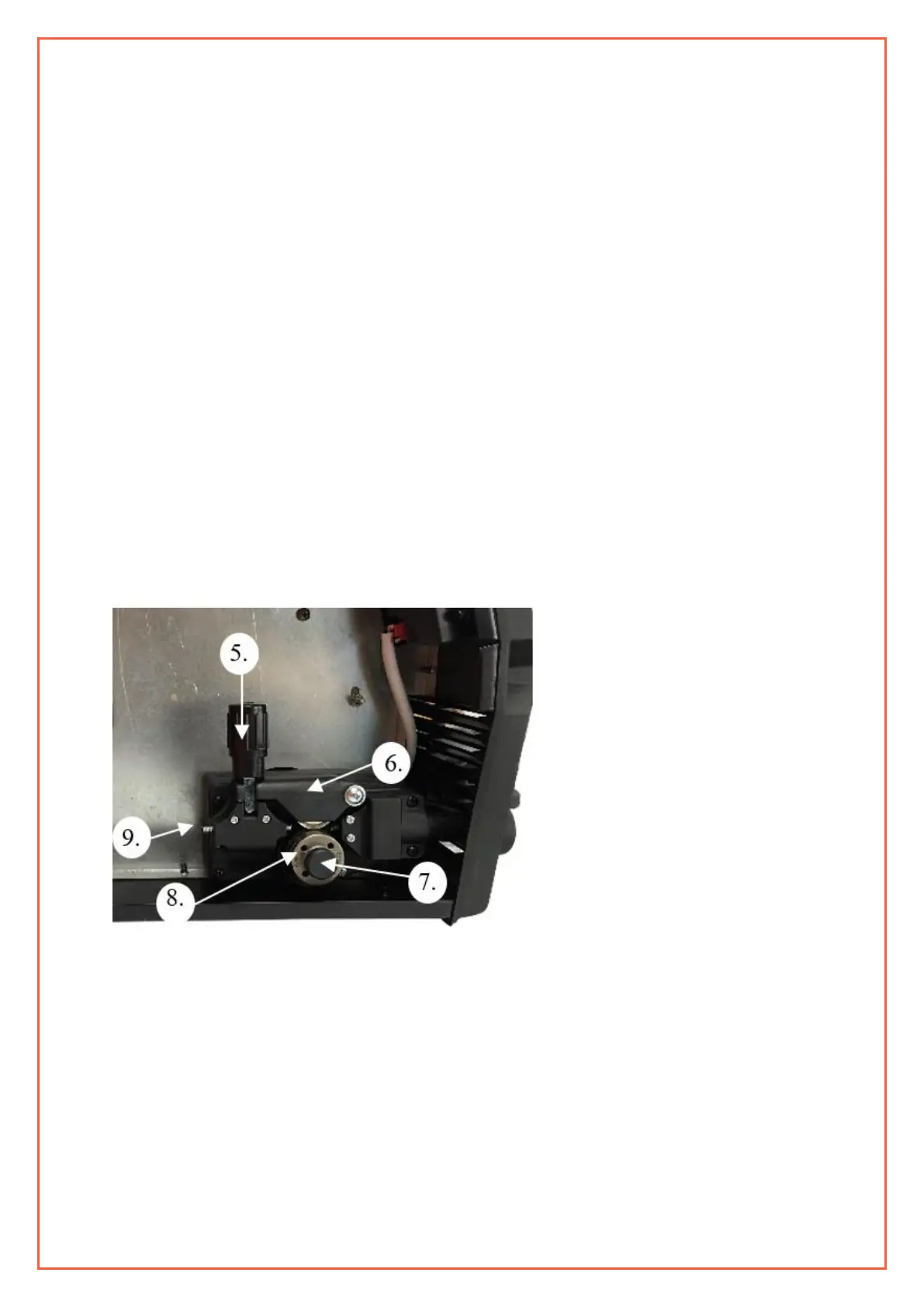

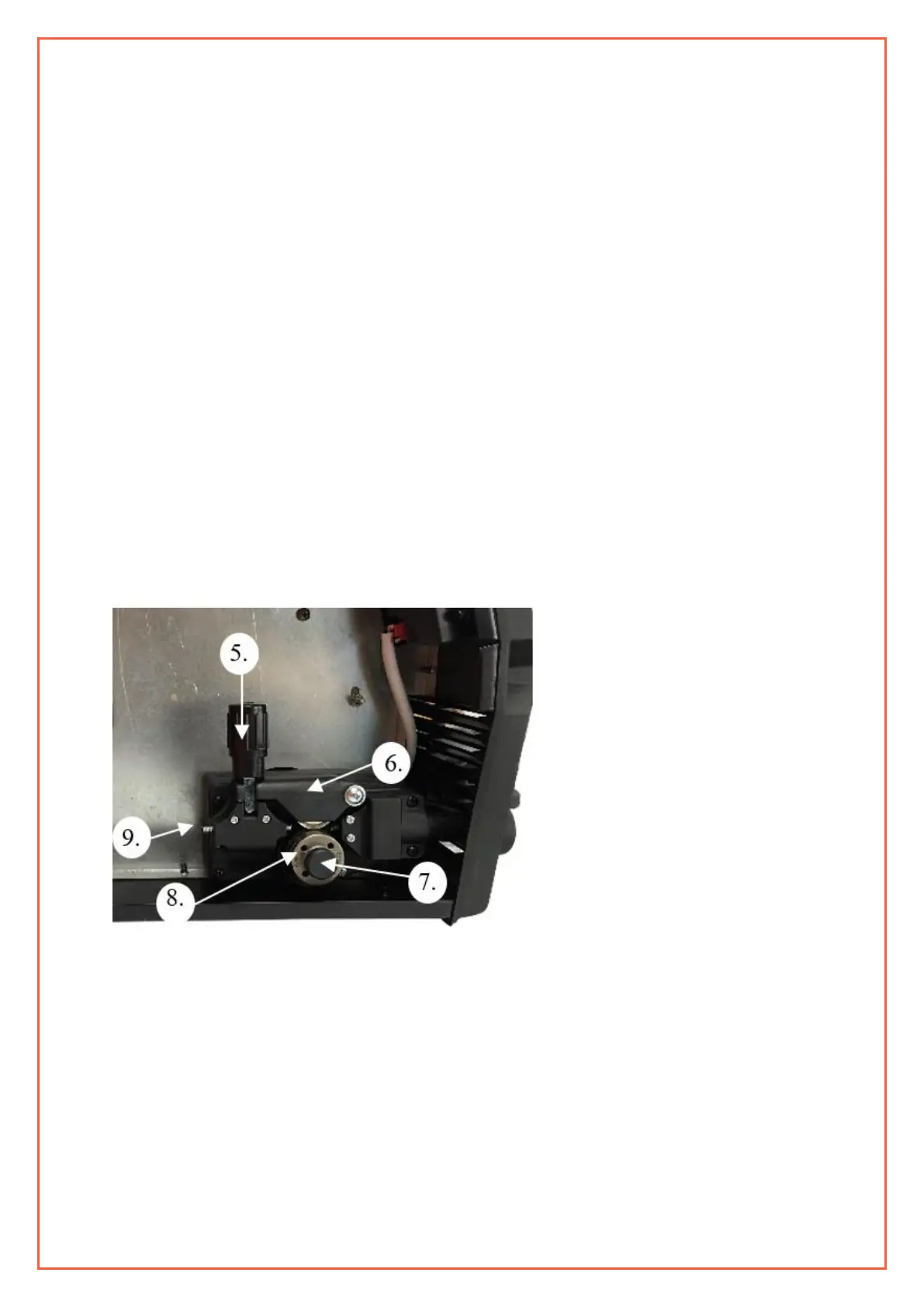

• Release the wire feeder tensioner arm (6) by pulling forward the tension adjustment knob (5).

Check the drive roller matches the wire type and wire diameter (size is stamped on the side of the roller).

“V” groove roller for solid hard gas shield wires – Mild steel and Stainless Steel.

“Knurled” roller for gasless/flux core.

To change the roller, undo the roller retainer bolt (7), slide off the roller, replace with the correct roller making sure

that the correct size groove lines up with the inlet guide tube (9). Tighten the retaining bolt anticlockwise, hand tight.

• Whilst holding the wire spool (this will prevent the spool uncoiling) carefully snip the wire and feed through the inlet

guide tube (9), over the roller and into the torch liner, feeding the wire approximately 50mm into the torch liner as this

will assist in feeding the wire through the torch.

• Align the wire into the grove of the roller and close the wire tensioner arm (6) and adjust the wire feed tensioner (5)

making sure the wire remains in the groove.

• Adjust the wire feed tension (5) by turning clockwise to increase the tension and anti-clockwise to reduce. Do not over

tighten the tension, the wire will be crushed – especially soft wires and flux cored wires.

Loading...

Loading...