14

SETUP FOR GAS MIG WELDING

Please ensure you have all relevant safety equipment and PPE ready.

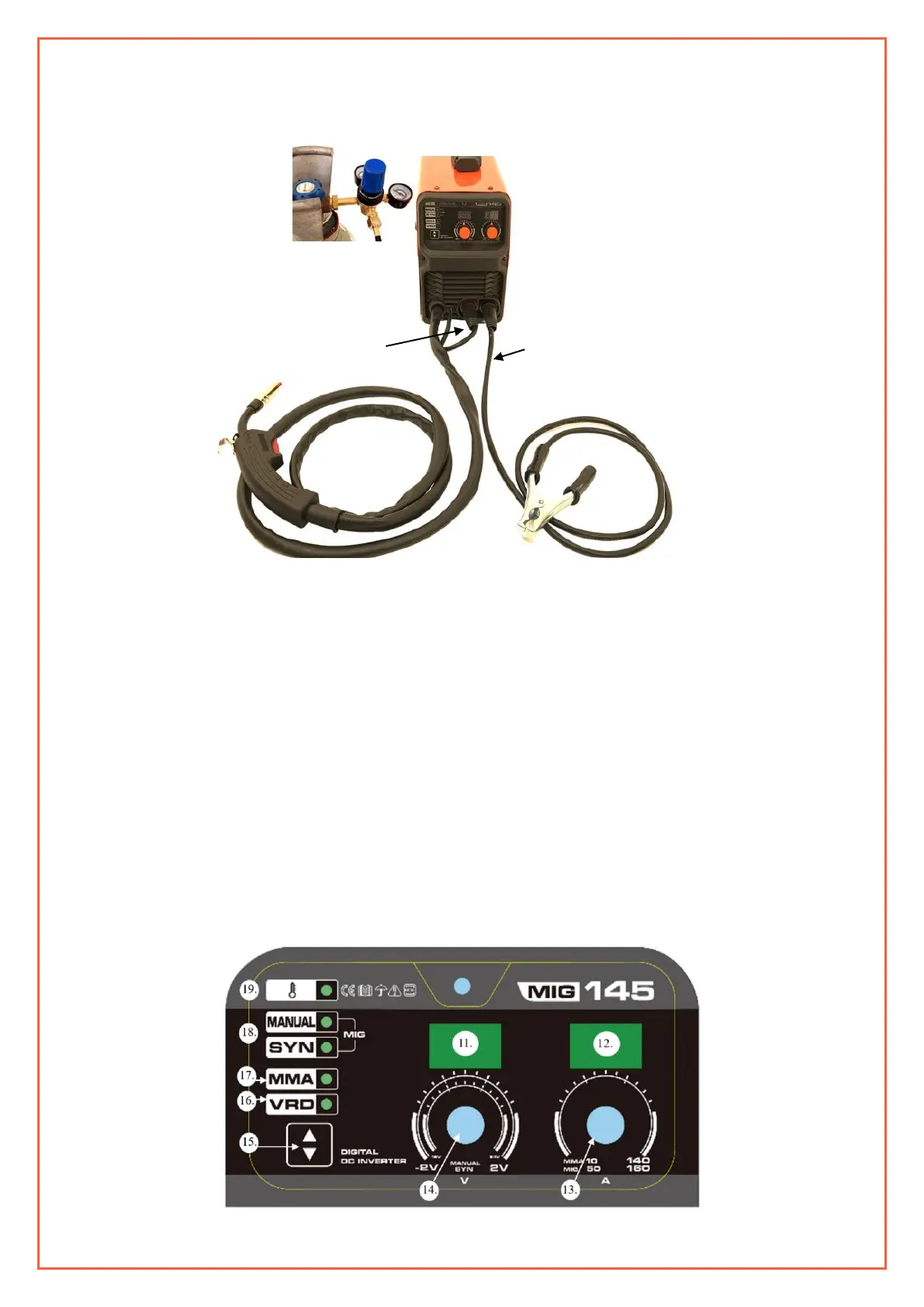

• Connect the optional Weldco Argon Regulator (WDC0812) to the argon cylinder or CO2 cylinder and connect the

gas line to the regulator.

• Connect the gas line from the regulator to the gas inlet on the back panel of the welder.

• Open the valve on the cylinder and set your gas flow rate between 5-10L/min. It is good practice to test for leaks.

Close the cylinder valve. If there are no leaks the regulator will maintain the set L/min and cylinder pressure values.

Always turn off your cylinder valve when not in use.

• Check that the correct gas shield wire, drive roller (8) and welding tip are fitted.

• Connect Polarity cable (3) to the positive + welding output terminal (1).

• Connect Earth Lead to the negative - output welding terminal (2).

• Connect Earth Clamp to the work piece. It is important the earth clamp makes strong contact with bare metal –

remove paint, rust or other contaminates to ensure strong contact. Failure to do so will reduce your welding

performance.

Loading...

Loading...