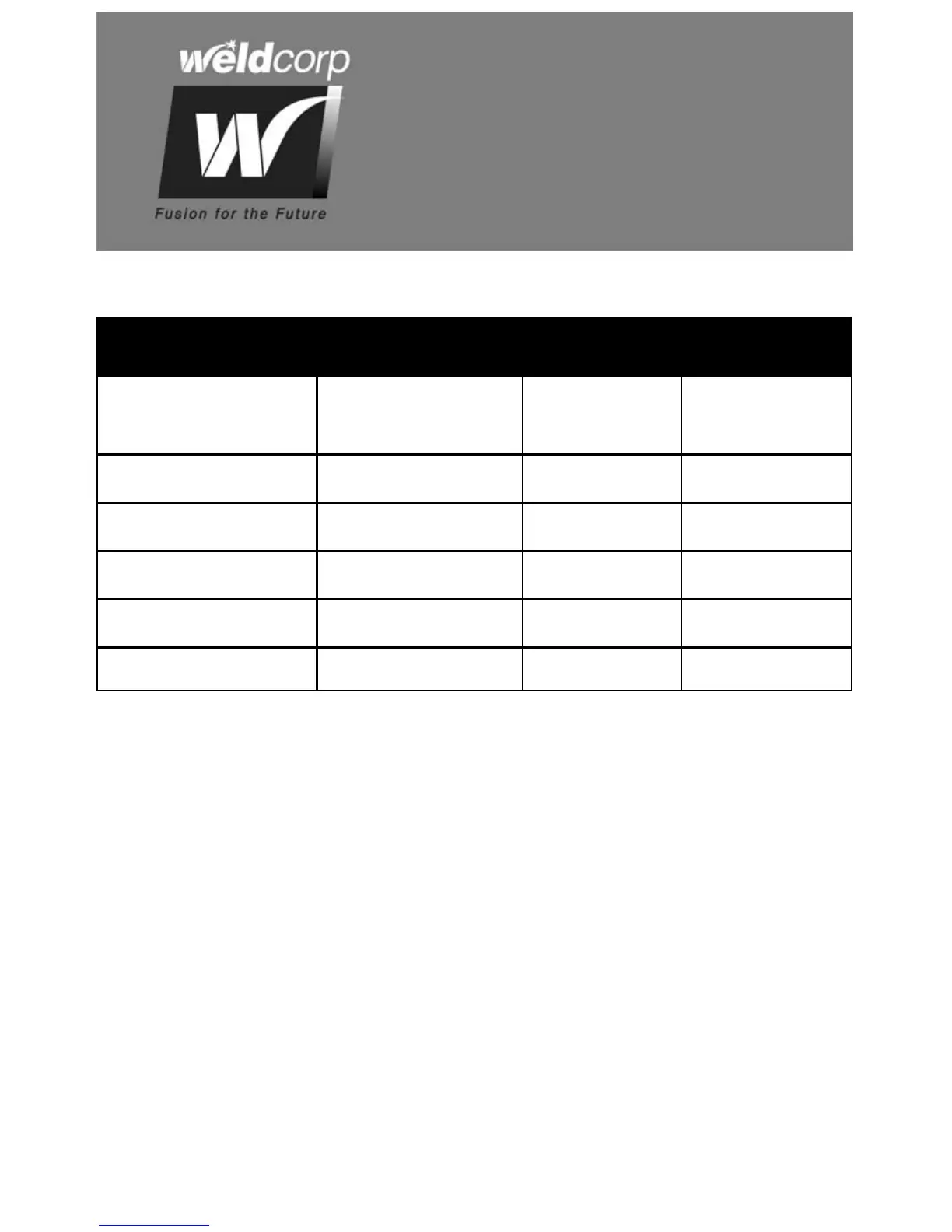

Weldable Metal

Thickness

Minimum

Current [A]

Maximum

Current [A]

1.20—1.50 mm 30 50

1.50—2.00 mm 40 80

2.00—4.00 mm 60 100

4.00—6.00 mm 100 130

6.00—7.00 mm 120 170

TABLE FOR SELECTION OF THE WELDING CURRENT ACCORDING TO THE

ELECTRODE AND METAL THICKNESS

Diameter Electrodes

E6013 / E7018

1.6 mm

2.0 mm

2.5 mm

3.2 mm

4.0 mm

NOTE: Weldable metal thickness can be increased by multiple welds.

Page 13

THERMAL OVERLOAD

NOTE:

This welder is fitted with a thermal overload cut out which operates automatically to

stop the transformer overheating. The machine will become operational again

automatically once the temperature has reduced itself to an acceptable

working temperature.

WELDING INFORMATION

KEY POINTS

Get the amperage right from the charts provided.

Check you have the right electrode.

Use the correct angle, 30—40 degrees to the work piece.

Arch weld from left to right.

Remember the safety aspects, preparation for welding and use the correct

equipment.

Loading...

Loading...