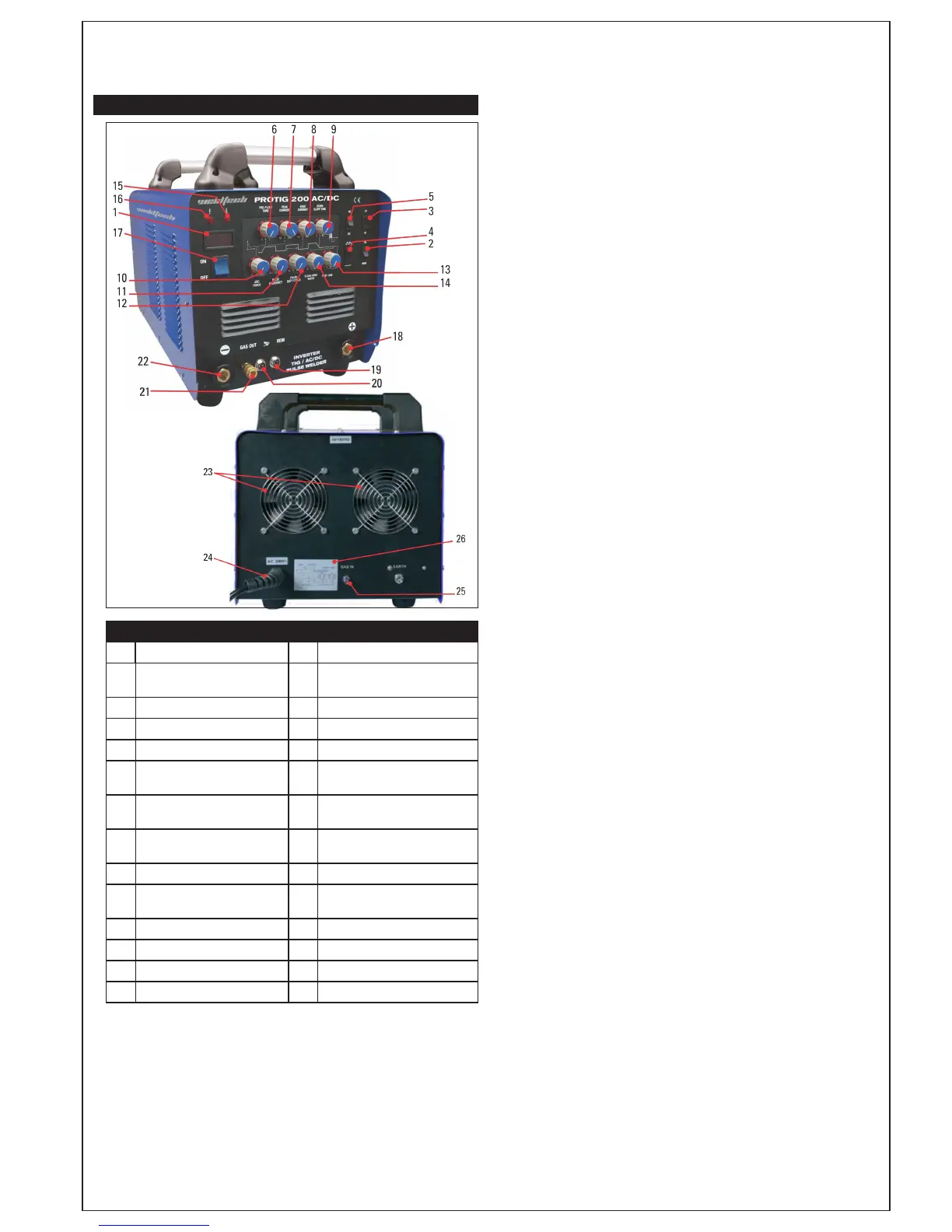

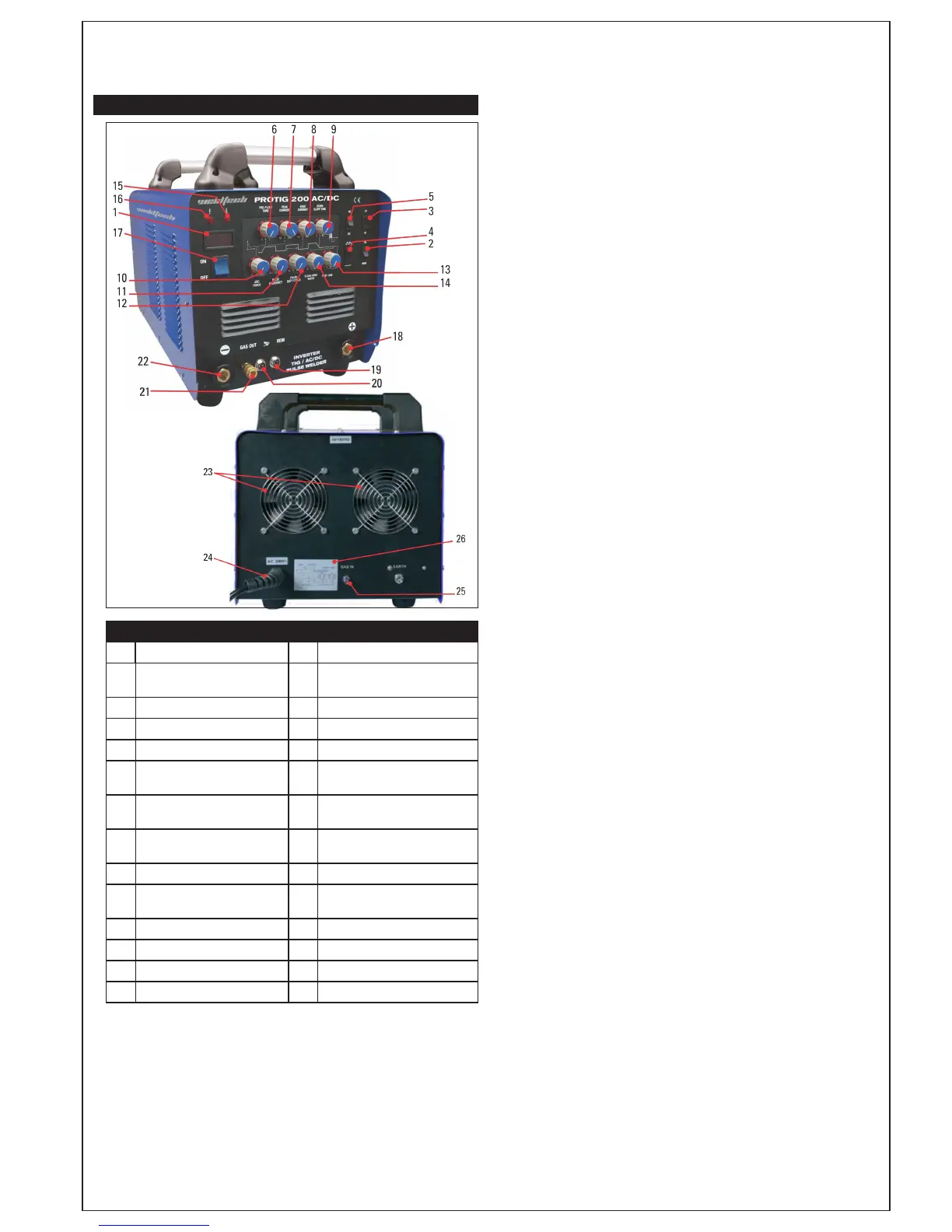

Function Reference Table

No. Description No. Description

1 LCD Current Meter 14

Clean Area Width/AC Balance

Adjustment

2 TIG/MMA Mode Switch 15

Mains Power On Indicator Lamp

3 2T/4T Trigger Mode Switch 16

Overload Indicator Lamp

4 Pulse Welding Mode Switch 17 Mains Power Switch

5 AC/DC Output Mode Switch 18

Positive (+) Welding Power

Output Terminal

6 Gas Pre-Flow Time Adjustment 19

Remote Current Control

Connection Socket

7 Peak Current Adjustment 20

Torch Switch Remote Connec-

tion Socket

8 Base Current Adjustment 21 Shielding Gas Outlet

9 Down Slope Adjustment 22

Negative (-) Welding Power

Output Terminal

10 ARC Force Adjustment 23 Cooling Fans

11 Pulse Frequency Adjustment 24 Mains Power Input Cable

12 Pulse Duty Adjustment 25 Gas Inlet Connector

13 Gas After-Flow Adjustment 26 Data Plate

4T/2T Trigger Control Switch (Ref. 3) - This switch controls the trigger mode for

the TIG torch trigger. 2T mode the trigger is depressed and held on to activate

the welding circuit, when the trigger is released, the welding circuit stops. 4T

is known as ’latching’ mode. The trigger is depressed once and released to

activate the welding circuit, depressed and released again to stop the welding

circuit. This function is useful for longer welds as the trigger is not required to

be held on continuously.

AC/DC Output Mode Switch (Ref. 5) - DC (direct current) output mode is

suitable for TIG welding metals such as mild steel and stainless steel, copper

and titanium. TIG welding reactive metals such as aluminium, magnesium and

zinc requires AC (alternating current) output.

When reactive metals are exposed to air they form an oxide layer that

insulates the base metal and prevents welding current flowing, it also

contaminates the weld area. Reverse current flow is required to break

through/ clean off this oxide layer so that welding can take place, while the

current flow during the positive cycle does the majority of the heating of the

weld pool area.

Pulse Welding Mode (Ref. 4) - Switches the welding output between a higher

and lower current output in a cyclic manner. When used correctly this function

provides greater weld penetration for less work heat input and greater control

of the weld pool.

Gas Pre-flow Time Adjustment (Ref. 6) - When the trigger is depressed, this

adjustment controls how long the gas flows before the arc is initiated. This is

necessary when purging the start of the weld area of any atmospheric gases

before the arc starts.

Peak Current Adjustment (Ref. 7) - Provides adjustment for the output current.

Base Current Adjustment (Ref. 8) - When using pulse mode, this adjustment

sets the current for the low/base pulse with respect to the peak current.

This is a percentage adjustment. E.g with the peak current set at 160A and the

base current adjustment set at 50%, the base current pulse will be 80A. (160A

x 50%). The basic theory for setting the base current using pulse mode is that

the base current should be sufficient to maintain the existing molten weld pool,

while the peak current is sufficient to melt new metal in order to move/ expand

the molten weld pool.

Down Slope Adjustment (Ref. 9) - When the trigger is released, this adjustment

causes the current to gradually decrease from the peak amps to 0 over the set

time (in seconds). To turn the function off, set the adjustment to 0. This function

is useful to prevent an uneven finish to the weld or a ‘crater’ forming when the

weld current stops abruptly.

Arc Force Adjustment (Ref. 10) - this adjustment impacts MMA, and has little

effect in TIG mode. The adjustment changes the characteristic of the volts/amp

relationship during welding. When MMA welding, output current is constant

as set, while the voltage changes with the arc length (the distance from the

electrode to the work piece). A shorter arc length will give a narrower weld

with more penetration, while a longer arc length gives a wider ‘colder’ weld

pool. A shorter arc can be unstable if the voltage gets too low. Increased arc

force adjustment will boost the welding voltage when it drops with a shorter

arc, giving a more penetrating arc when used with short arc length.

A basic rule of thumb is increased arc force will give an arc characteristic that

feels more penetrating and tight, while decrease in arc force will give a softer,

less focused arc.

Pulse Frequency Adjustment (Ref. 11) - Pulse mode sets the rate that the

output current switches between high and low. Increased pulse frequency

will have the effect of making the arc more tightly focused, which is useful for

fine stainless work and similar. A slow pulse rate can be used to help move the

weld pool along, this technique is useful with welding Aluminium, as molten

Aluminium forms a more viscous ‘sticky’ weld pool.

Pulse Duty Adjustment (Ref. 12) - This adjustment sets the time proportion as

a percentage between the peak current and base current when using pulse

mode. Neutral setting is 50%, the time period of the peak current and base

current pulse is equal. Higher pulse duty setting will give greater heat input,

while lower pulse duty will have the opposite effect.

Clean Width Area/ AC Balance Adjustment (Ref. 14) - Sets the balance

between the forward and reverse current cycles when welding in AC output

mode. The reverse part of the cycle gives the ‘cleaning’ effect on the weld

material, while the forward cycle melts the weld material. Neutral setting is

50%. Increased reverse cycle bias will give greater cleaning effect, less weld

penetration and more heat in the torch tungsten, reducing the output current

that can be used for a given tungsten size. Increased forward cycle bias will

give the opposite effect, less cleaning effect, greater weld penetration and

less heat in the tungsten. Ideally for maximum effectiveness, the clean width/

AC balance should be set with as much forward cycle bias as possible, while

still maintaining a sufficient level of oxidisation removal for a contamination

free weld pool. The cleaner the metal, the more effective it is to weld.

Gas After-flow Adjustment (Ref. 13) - This adjustment sets the period of time

that the gas control valve stays open. It is important for TIG welding that that

the weld pool and the torch tungsten remain protected from atmospheric

contamination by the shielding gas until they have cooled sufficiently.

The tungsten should be able to be touched by hand before the shielding gas

stops flowing.

Remote Current Control Connection Socket (Ref. 19) - For connection of a

torch with external amperage control capability. Refer consumables and

accessories section for a suitable upgrade torch part number.

Overload Indicator Lamp (Ref. 16) - Lights when duty cycle is exceeded and

thermal protection is activated. When activated, welding output will

be disabled until machines cools sufficiently and overload indicator lamp

goes out.

KNOW YOUR WELDER

Loading...

Loading...