TIG WELDING GUIDE

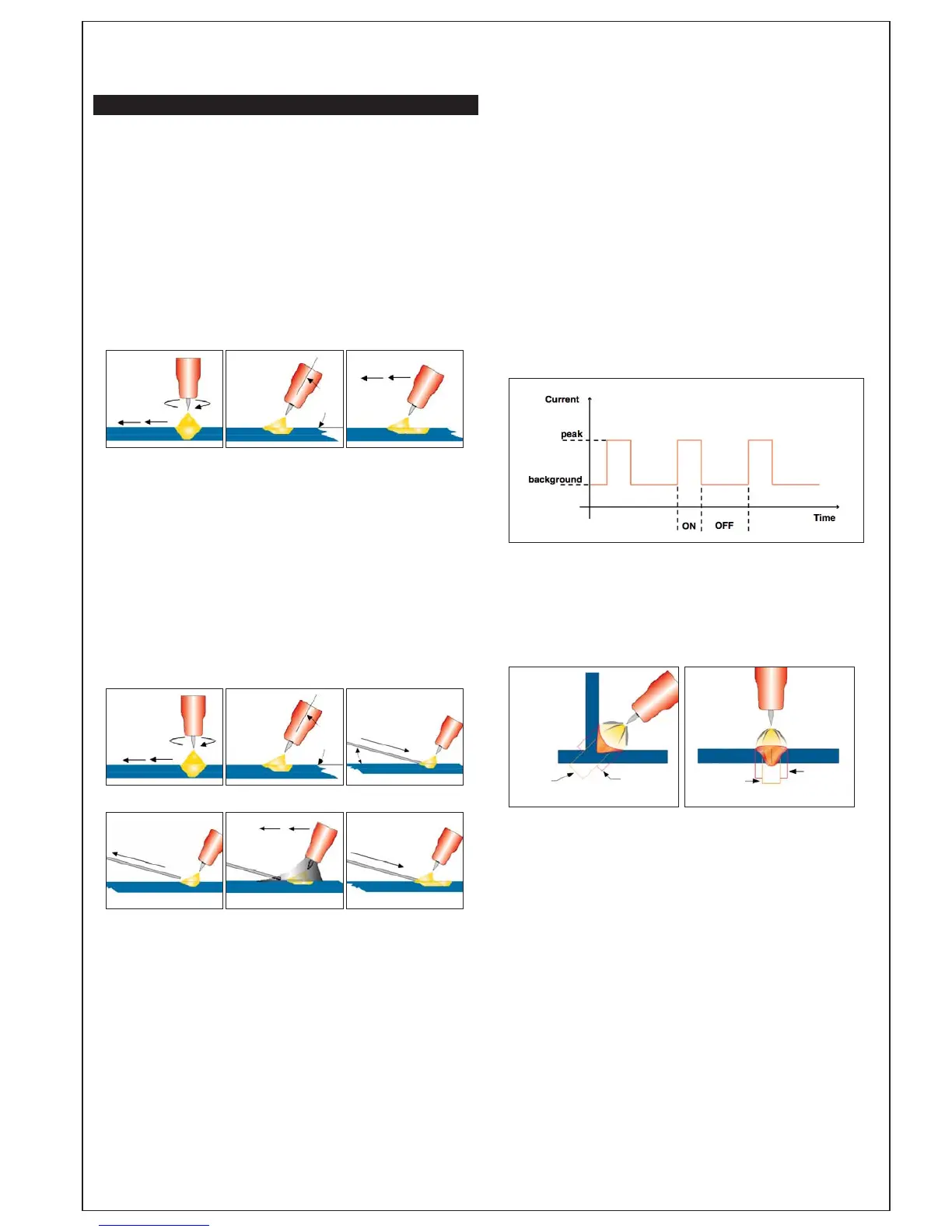

TIG WELDING FUSION TECHNIQUE

Manual TIG welding is often considered the most difficult of all the

welding processes. Because the welder must maintain a short arc length,

great care and skill are required to prevent contact between the electrode

and the work piece. Similar to Oxygen Acetylene torch welding, TIG welding

normally requires two hands and in most instances requires the welder to

manually feed a filler wire into the weld pool with one hand while manipulating

the welding torch in the other. However, some welds combining thin materials

can be accomplished without filler metal like edge, corner, and butt joints.

This is known as Fusion welding where the edges of the metal pieces are

melted together using only the heat and arc force generated by the TIG arc.

Once the arc is started the torch tungsten is held in place until a weld pool is

created, a circular movement of the tungsten will assist is creating a weld pool

of the desired size. Once the weld pool is established tilt the torch at about

a 75° angle and move smoothly and evenly along the joint while fusing the

materials together.

TIG WELDING WITH FILLER WIRE TECHNIQUE

In many situations with TIG welding, it is necessary to add a filler wire into the

weld pool to build up weld reinforcement and create a strong weld. Once the

arc is started the torch tungsten is held in place until a weld pool is created,

a circular movement of the tungsten will assist is creating a weld pool of

the desired size. Once the weld pool is established tilt the torch at about a

75° angle and move smoothly and evenly along the joint. The filler metal is

introduced to the leading edge of the weld pool. The filler wire is usually held

at about a 15° angle and fed into the leading edge of the molten pool, the arc

will melt the filler wire into the weld pool as the torch is moved forward. Also a

dabbing technique can be used to control the amount of filler wire added, the

wire is fed into the molten pool and retracted in a repeating sequence as the

torch is moved slowly and evenly forward. It is important during the welding to

keep the molten end of the filler wire inside the gas shield as this protects the

end of the wire from being oxidised and contaminating the weld pool.

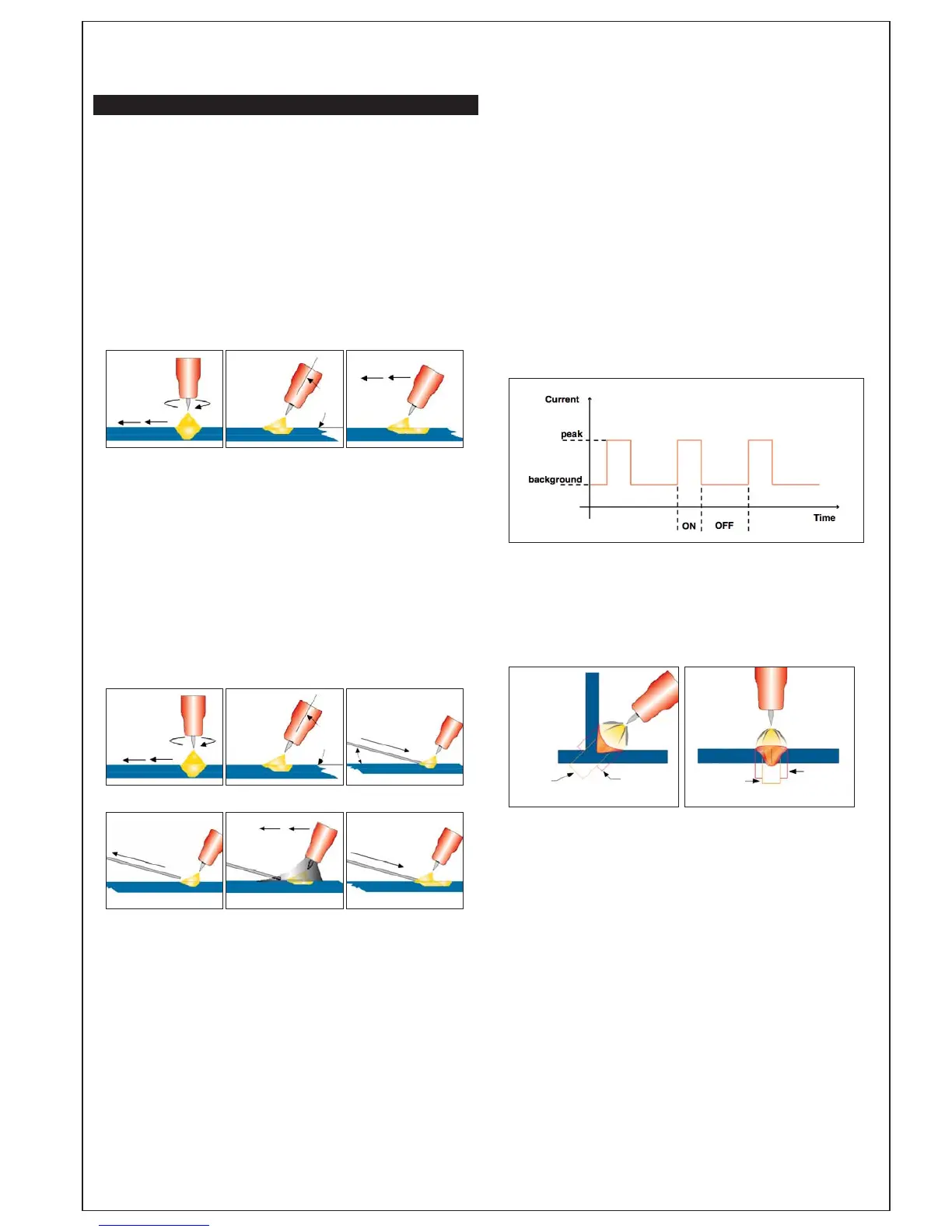

PULSE TIG WELDING

Pulse TIG welding is when the current output (amperage) changes between

high and low current.

Electronic controls within the welding machine create the pulse cycle.

Welding is done during the high-amperage interval (this high amperage is

referred to as peak current). During the low amperage period, the arc is

maintained but the current output of the arc is reduced (this low amperage is

referred to as base current). During pulse welding the weld pool cools during

the low amperage period. This allows a lower overall heat input into the base

metal. It allows for controlled heating and cooling periods during welding

providing better control of heat input, weld penetration, operator control and

weld appearance.

There are 4 variables within the pulse cycle:

Peak Current - Base Current - Pulse Frequency - Pulse Width

Setting and manipulation of these variables will determine the nature of the

weld current output and is at the discretion of the operator.

Peak Current is the main welding current (amps) set to melt the material being

welded and works much the same as setting maximum amperage values for

regular DC TIG: as a guide use 30-40 amps for every 1mm of material thickness.

Base Current is the set level of background current (amps) which cools the

weld puddle and affects overall heat input. Background Amps is a percentage

of peak amperage. As a rule, use enough background current to reduce the

weld pool to about half its normal size while still keeping the weld pool fluid. As

a guide start by setting the background amperage at 20 to 30 percent of peak

amperage.

Pulse Frequency is the control of the amount of times per second (Hz) that the

welding current switches from Peak Current to Base Current. DC Pulse TIG

frequency generally ranges from 20 to 300 HZ depending on the job application.

Control of the pulse frequency also determines the appearance of the weld.

Pulse Width is the control of the percentage of time during one pulsing cycle

the power source spends at the peak current (main amperage). Example is

with the Pulse Width set at 80 percent and a rate of 1 pulse per second (PPS),

the machine will spend 80% of the pulse at peak amperage and 20% at the

base current. Increasing the pulse width percentage adds more heat to the

job, while decreasing pulse width percentage reduces heat.

Pulse TIG welding allows faster welding speeds with better control of the heat

input to the job, reducing the heat input minimising distortion and warping of

the work and is of particular advantage in the welding of thin stainless steel

and carbon steel applications. The high pulse frequency capability of the

advanced inverter agitates the weld puddle and allows you to move quickly

without transferring too much heat to the surrounding metal. Pulsing also

constricts and focuses the arc thus increasing arc stability, penetration and

travel speeds.

TUNGSTEN ELECTRODES

Tungsten is a rare metallic element used for manufacturing TIG welding

electrodes. The TIG process relies on tungsten’s hardness and high-

temperature resistance to carry the welding current to the arc. Tungsten has

the highest melting point of any metal at 3410 degrees Celsius.

Tungsten electrodes are non-consumable and come in a variety of sizes, they

are made from pure tungsten or an alloy of tungsten and other rare earth

elements. Choosing the correct tungsten depends on the material being

welded, the amount of amps required and whether you are using AC or DC

welding current.

Tungsten electrodes are colour-coded at the end for easy identification.

Thoriated

Thoriated tungsten electrodes (AWS classification EWTh-2) contain a

minimum of 97.30 percent tungsten and 1.70 to 2.20 percent thorium and are

called 2 percent thoriated. They are the most commonly used electrodes today

and are preferred for their longevity and ease of use. Thorium increases the

electron emission qualities of the electrode, which improves arc starts and

allows for a higher current-carrying capacity. This electrode operates far

below its melting temperature, which results in a considerably lower rate of

consumption and eliminates arc wandering. Compared with other electrodes,

thoriated electrodes deposit less tungsten into the weld puddle, so they cause

less weld contamination.

Travel Direction

Travel Direction

Gas

shield

Form a weld pool

Form a weld pool

Retract the filler wire

Angle Torch

Angle Torch

High

Frequency

Pulsing

High

Frequency

Pulsing

No pulse

No pulse

Move the torch forward to the

front of the weld pool

Move the Torch slowly and

evenly forward

Add TIG filler wire

Repeat the process

75˚

75˚

15˚

Loading...

Loading...