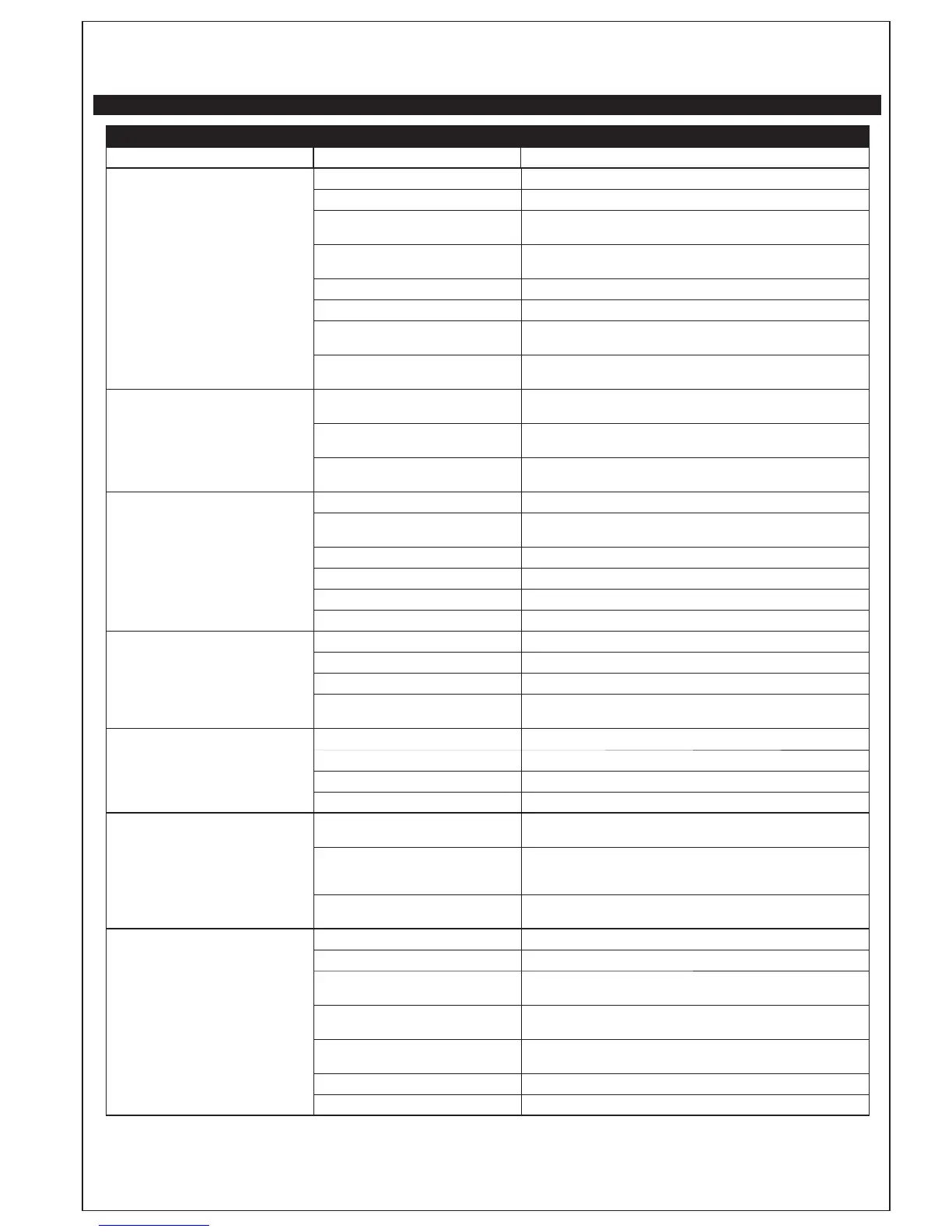

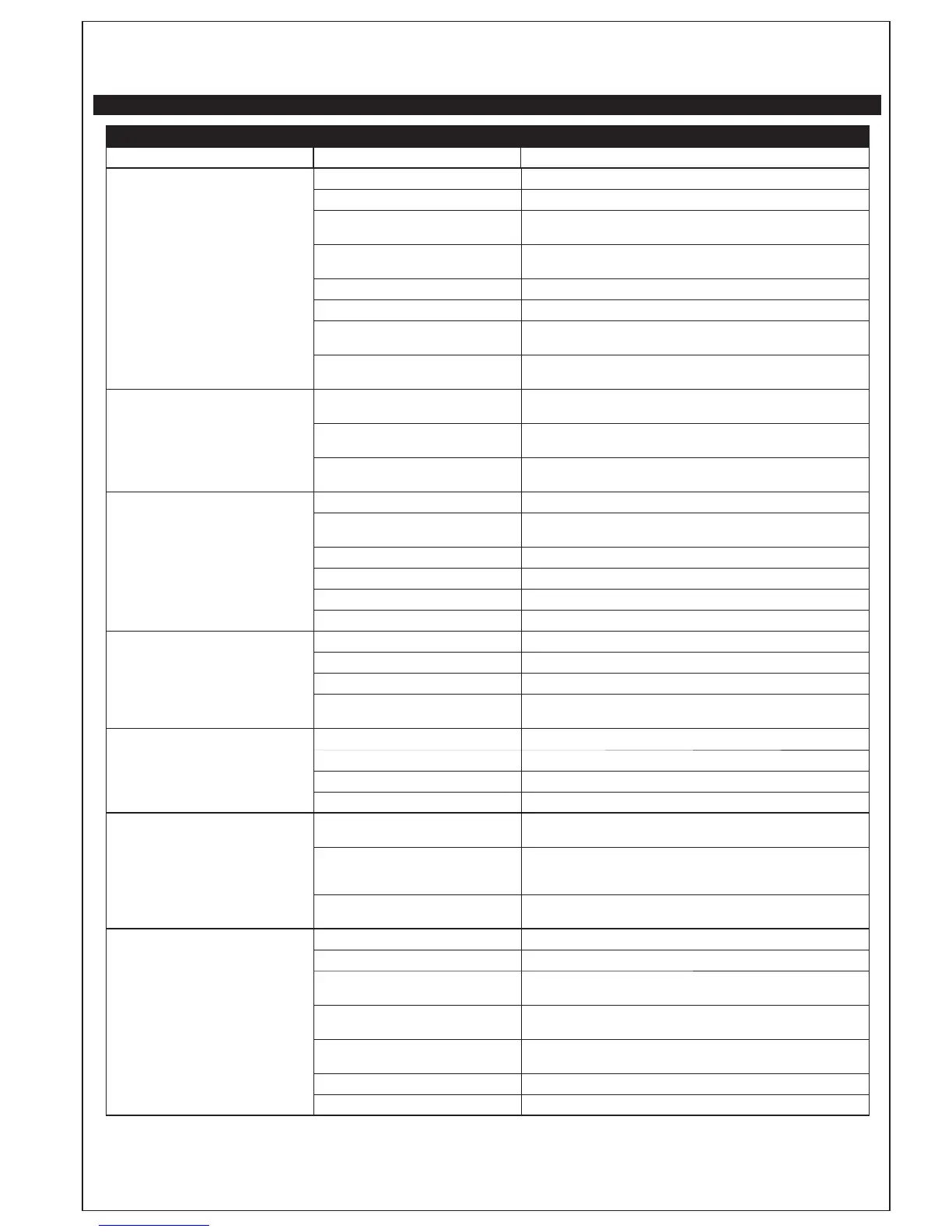

TIG WELDING TROUBLESHOOTING

Troubleshooting - TIG Weld Quality

Fault Cause Remedy

Tungsten burning away quickly Incorrect gas Check that pure Argon is being used

No gas Check the gas cylinder contains gas and is connected

Inadequate gas flow

Check the gas is connected, check hoses, gas valve and torch are not

restricted. Set the gas flow between 10 - 15 l/min flow rate

Back cap not fitted correctly

Ensure the torch back cap is fitted so that the o-ring is inside the torch

body

Torch connected to DC + Connect the torch to the DC- output terminal

Incorrect tungsten being used Check and change the tungsten type if necessary

Tungsten being oxidised after weld is

finished

Keep shielding gas flowing 10–15 seconds after arc stoppage. 1 second

for each 10 amps of weld current.

T

ungsten melting back into the nozzle on

AC welding

Check that correct type of tungsten is being used. Check the balance

control is not set too high on the balance - reduce to a lower setting

Contaminated Tungsten

Touching tungsten into the weld pool

Keep tungsten from contacting weld puddle. Raise the torch so that the

tungsten is off of the work piece 2 - 5mm

Touching the filler wire to the tungsten

Keep the filler wire from touching the tungsten during welding, feed the

filler wire into the leading edge of the weld pool in front of the tungsten

Tungsten melting into the weld pool

Check that correct type of tungsten is being used. Too much current for

the tungsten size so reduce the amps or change to a larger tungsten

Porosity - Poor weld appearance

and colour

Incorrect gas Check that pure Argon is being used

Inadequate gas flow / gas leaks

Check the gas is connected and cylinder valve open, check hoses, gas

valve and torch are not restricted. Set the gas flow between 10 - 15 l/min

Moisture on the base metal Remove all moisture from base metal before welding

Contaminated base metal Remove materials like paint, grease, oil, and dirt, including mill scale

Contaminated filler wire Remove all grease, oil, or moisture from filler metal.

Incorrect filler wire Check the filler wire and change if necessary

Yellowish residue / smoke on the

alumina nozzle & discoloured tungsten

Incorrect Gas Use pure Argon gas

Inadequate gas flow Set the gas flow between 10 - 15 l/min flow rate

Inadequate post flow gas Increase the post flow gas time

Alumina gas nozzle too small for size of

tungsten being used

Increase the size of the alumina gas nozzle

Unstable Arc during welding Torch connected to DC + Connect the torch to the DC- output terminal

Contaminated base metal Remove materials like paint, grease, oil, and dirt, including mill scale

Tungsten is contaminated Remove 10mm of contaminated tungsten and re grind the tungsten

Arc length too long Lower torch so that the tungsten is off of the work piece 2 - 5mm

HF present but no welding power

Incomplete welding circuit

Check earth lead is connected. Check all cable connections. If using a

water cooled torch check that the power cable is not separated.

No gas

Check the gas is connected and cylinder valve open, check hoses, gas

valve and torch are not restricted. Set the gas flow between 10 - 15 l/min

Tungsten melting into the weld pool

Check that correct type of tungsten is being used. Too much current for

the tungsten size so reduce the amps or change to a larger tungsten

Arc wanders during welding Poor gas flow Check and set the gas flow between 10 - 15 l/min flow rate

Incorrect arc length Lower torch so that the tungsten is off of the work piece 2 - 5mm

Tungsten incorrect or in poor condition

Check that correct type of tungsten is being used. Remove 10mm from the

weld end of the tungsten and re sharpen the tungsten

Poorly prepared tungsten

Grind marks should run lengthwise with tungsten, not circular. Use proper

grinding method and wheel.

Contaminated base metal

Remove contaminating materials like paint, grease, oil, and dirt, including

mill scale from base metal.

Contaminated filler wire Remove all grease, oil, or moisture from filler metal.

Incorrect filler wire Check the filler wire and change if necessary

Loading...

Loading...