Completing Installation

15. Using appropriately sized tubing, connect from the sample outlet to an appropriate customer-supplied sample

container, such as a Welker TCCTransportable Crude Oil Container for crude oil or a Welker Constant Pressure Cylinder

for light liquids (Figure 2, Figure 3, Figure 4, Figure 5, or Figure 6 and Table 2).

If the inLoop™ ACE is not equipped with a valve on the sample outlet, Welker recommends installing a valve to the sample

outlet. This will be outlet valve A.

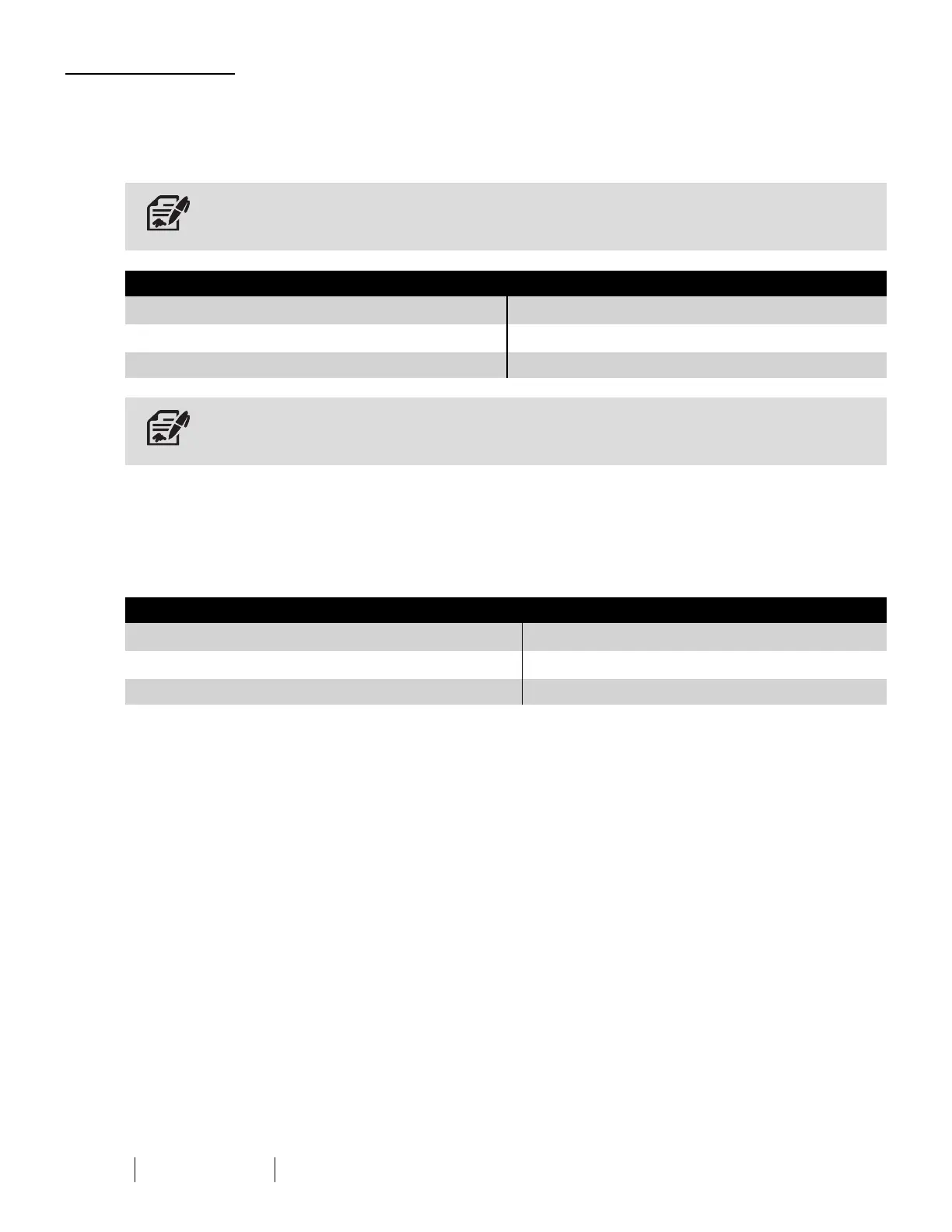

Table 2: Recommended Tubing Size – Sample Container

Product Sampled Tubing Size

Light Liquids or Light Crude Oil Minimum ¼"

Medium or Heavy Crude Oil Minimum ³⁄₈"

Customer-supplied tubing must slope downward from the inLoop™ ACE to the sample container.

16. Using appropriately sized tubing, connect from the normally open port on the solenoid to port A on the motor housing

(Figure 2, Figure 3, Figure 4, Figure 5, or Figure 6 and Table 3). Using appropriately sized tubing, connect from the

normally closed port on the solenoid to port B on the motor housing (Figure 2, Figure 3, Figure 4, Figure 5, or Figure 6

and Table 3).

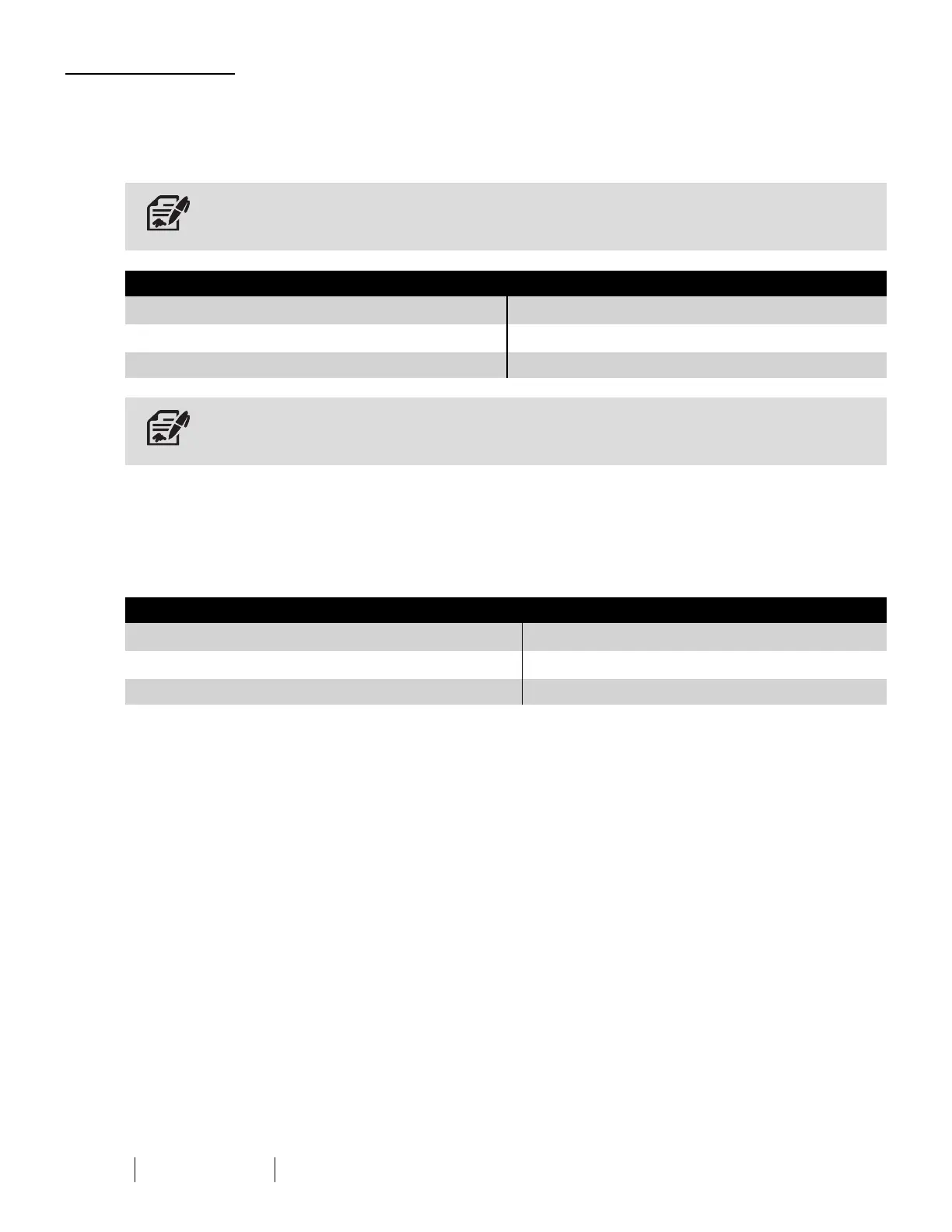

Table 3: Recommended Tubing Size – Motor Operation

Utility Supply for Motor Operation Tubing Size

Pneumatics Minimum ¼"

Hydraulics Minimum ³⁄₈"

17.

If applicable, ensure that outlet valve A is closed (Figure 3 or Figure 4).

18.

If applicable, ensure that the optional external sand relief has been set (Figure 3 or Figure 4).

19. If applicable, ensure that the customer constant pressure cylinder has been pre-charged and that all cylinder valves are

closed.

20. Pressurize the fast loop.

21. Check for leaks and repair as necessary.

12

IOM-224 MODEL: INLOOP™ ACE REV: A 13839 West Bellfort Street, Sugar Land, TX 77498 welker.com Service Department 281.491.2331

Loading...

Loading...