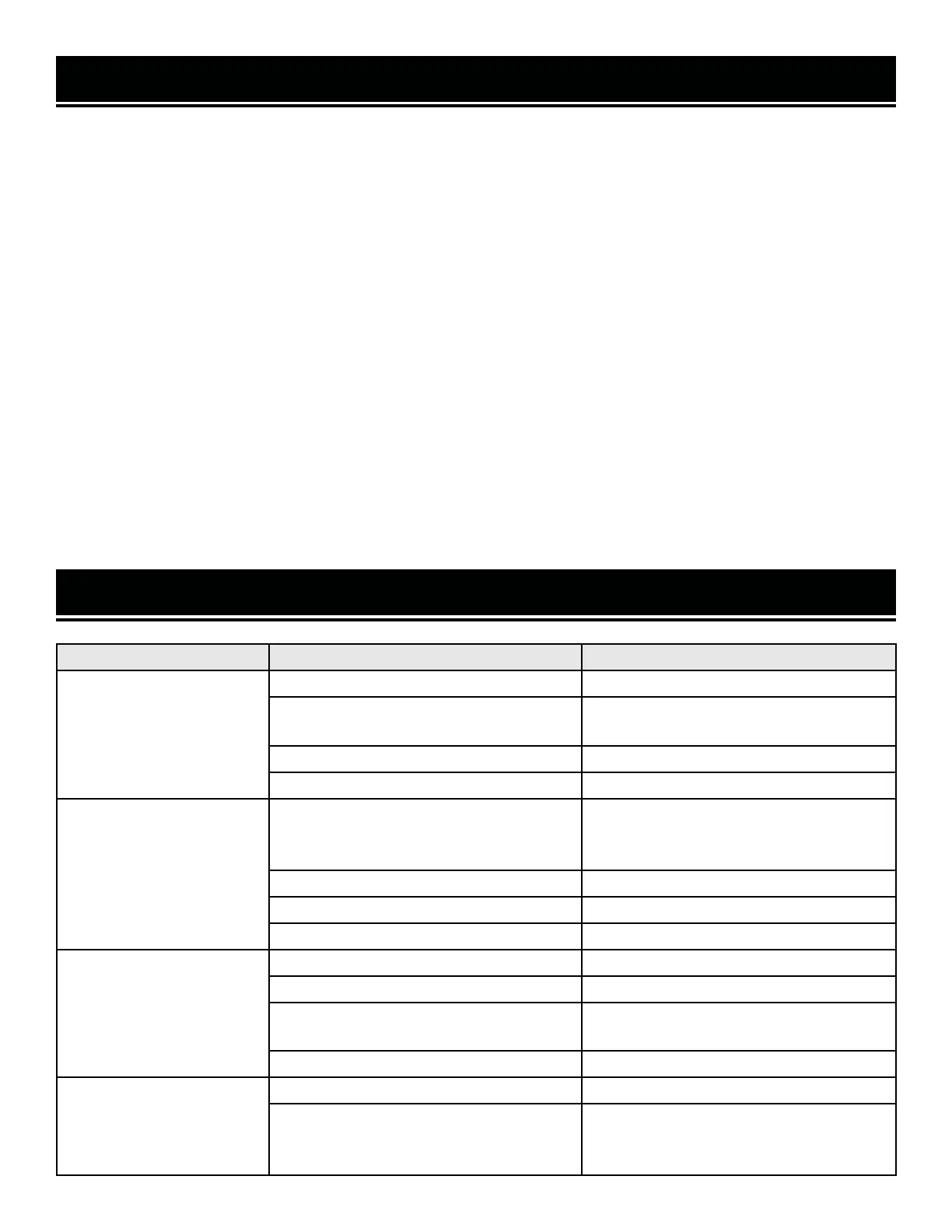

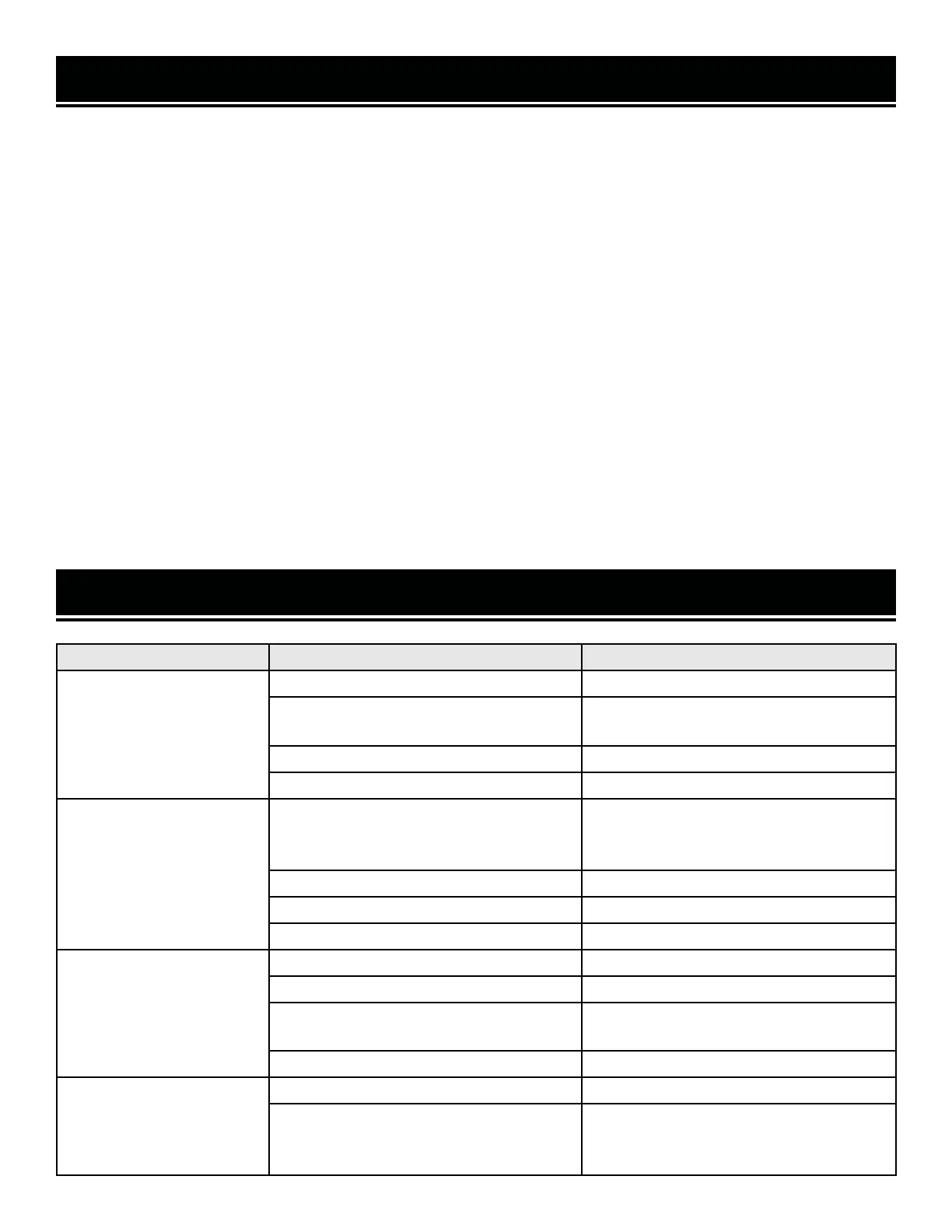

PROBLEM CAUSE SOLUTION

Motor or spindle stalls

and will not start.

1. Excessive cut 1. Reduce the depth of the cut.

2. Worn, damaged, or improperly ad-

justed belt.

2. Adjust or replace the belt.

3. Worn spindle bearing. 3. Replace the bearing.

4. Motor is protected from overload. 4. Reset the circuit.

Excessive vibration.

1. Workpiece is warped, out of round,

has major flaw, or was improperly pre-

pared for turning.

1. Correct the problem by planing or

sawing workpiece, or discard it entirely

and restart.

2. Worn spindle bearing. 2. Replace the spindle bearings.

3. Worn drive belt. 3. Replace the drive belt.

4. Lathe is on an uneven surface. 4. Place the lathe on a flat surface.

Tools tend to grab or dig

in.

1. Dull tools. 1. Keep tools sharp.

2. Tool rest set too low. 2. Reposition the tool rest height.

3. Tool rest set too far from work piece.

3. Reposition the tool rest closer to the

workpiece.

4. Improper tool being used. 4. Use correct tool for operation.

Tailstock moves when ap-

plying pressure.

1. Cam lock nut needs adjusting. 1. Tighten cam lock nut.

2. Lathe bed and tailstock mating sur-

faces are greasy or oily.

2. Remove the tailstock and clean the

surfaces with a cleaner. Apply a light

coat of oil to the lathe bed surface.

MAINTENANCE

Keep your machine clean. At the end of each day, clean the machine. Wood contains moisture, meaning that saw-

dust and wood chips can cause rust if not removed. Regular oil attracts dust and dirt. Teflon lubricant tends to dry

and has less of a tendency to accumulate dirt and saw dust. Periodically check that all nuts and bolts are tight.

The drive belt should last for many years depending on usage, but it needs to be inspected regularly for cracks, cuts

and general wear. If damage is found, replace the belt before operation.

All bearings are sealed for life and do not require any maintenance. If a bearing becomes faulty, replace it.

The lathe is made from steel and cast iron. All non-painted surfaces will rust if not protected. Apply a light coat of

good-quality paste wax to all machined surfaces to protect against rust and corrosion.

Blow out dust accumulation inside the motor, the housing, and the bed assembly frequently. If the tailstock has been

used as a guide for drilling through the center of a workpiece, also blow sawdust or shavings out of the center of

both the headstock spindle and the tailstock quill.

A coat of machine lubricant applied to the bed will help keep the surface clean and the movement of the tool rest

and tailstock smooth.

Periodic lubrication of the spring levers and other threaded parts will make these parts easier to operate.

TROUBLESHOOTING GUIDE

18

Loading...

Loading...