11

Fig. E

Fig. F

ASSEMBLY AND ADJUSTMENTS

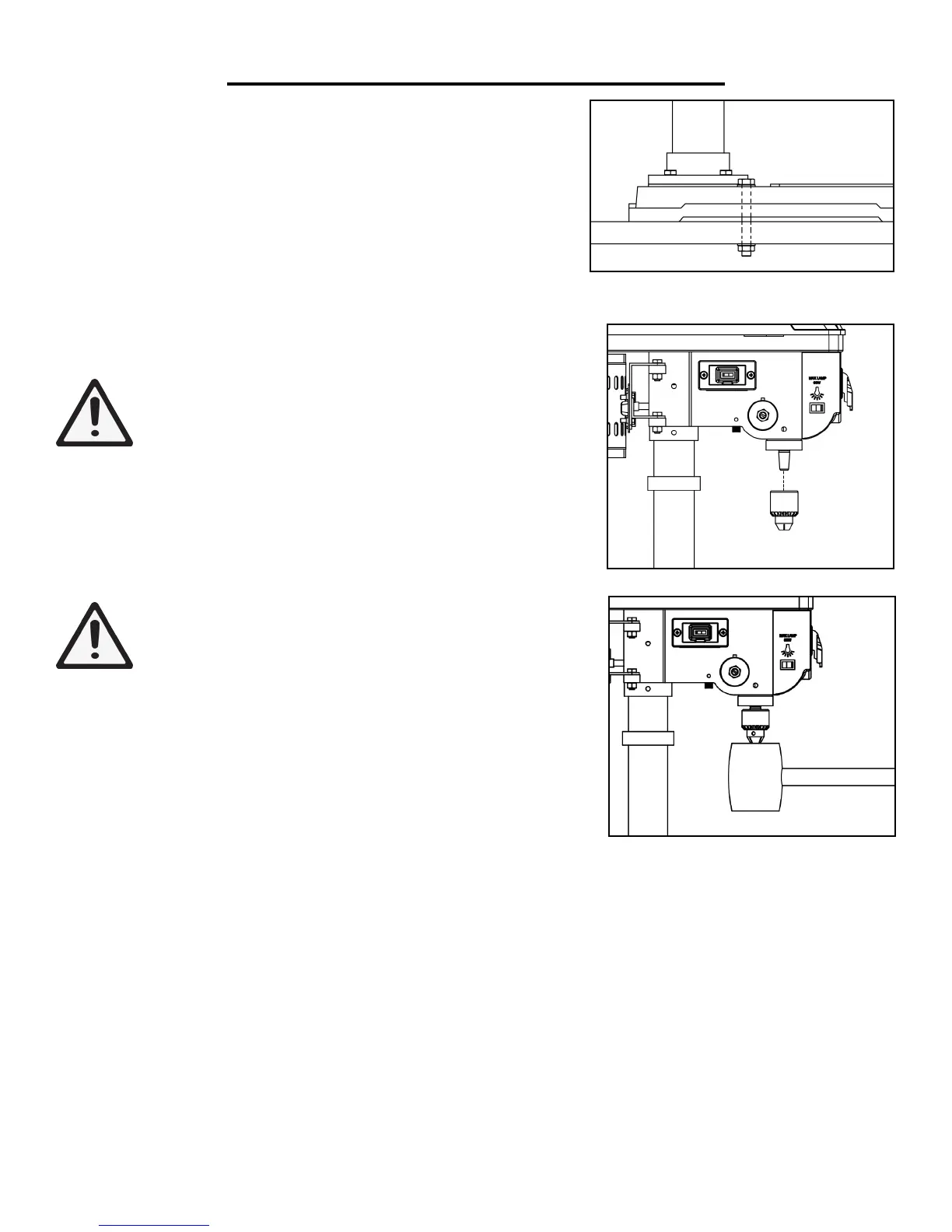

MOUNT THE DRILL PRESS (Fig. H)

The drill press must be securely fastened through the mounting holes to

a stand or workbench with heavy-duty fasteners (Fig. H). This will pre-

vent the drill press from tipping over, sliding, or walking during opera-

tion.

IMPORTANT: If the stand or workbench has a tendency to move dur-

ing operation, fasten the workbench securely to the floor.

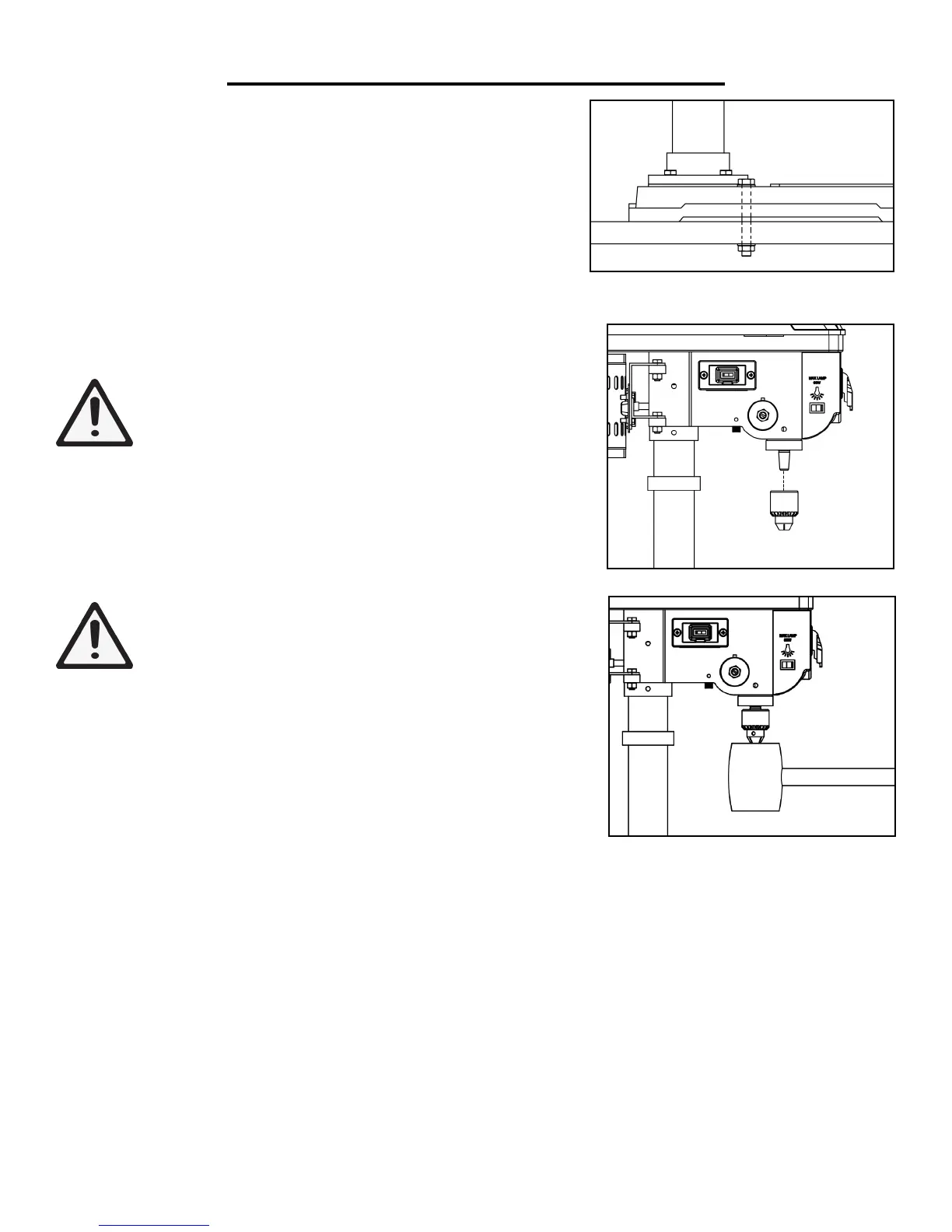

INSTALL THE CHUCK

WARNING: Before any assembly of the chuck to the drill

press spindle, clean all mating surfaces with a non-petroleum

based product; such as alcohol or lacquer thinner. Any oil or

grease used in the packing of these parts must be removed;

otherwise the chuck may come loose during operation.

1. Inspect and clean the taper hole in the chuck and the spindle. Remove

all grease, coatings, and particles from the chuck and spindle surfaces with

a clean cloth.

CAUTION: To avoid damaging the chuck, make sure the

jaws are completely recessed into the chuck. Do not use a

metal hammer to drive the chuck into the spindle.

2 . Align the chuck with the spindle. (Fig. I)

3. Using a wood mallet, firmly tap the chuck upward into position on the

spindle (Fig. J). Alternatively, you can use a block of wood and a regular

hammer, using the wood to cushion the blow and prevent damage to the

chuck.

REMOVE THE CHUCK

If you ever need to remove the chuck:

1. Turn the feed handles to lower the chuck to the lowest position.

2. Place a ball joint separator above the chuck and tap it lightly with a hammer to cause the chuck to drop from

the spindle.

Note: To avoid possible damage to the drill or chuck, be prepared to catch the chuck as it falls.

Fig. H

Fig. I

Fig. J

Loading...

Loading...