MAINTENANCE

WARNING! To prevent serious injury from accidental operation, make sure that the planer is turned off and

unplugged from power source before installation, cleaning and maintenance operations.

WARNING! Preventive maintenance performed by unauthorized personnel may result in misplacing of inter-

nal wires and components, possibly causing a serious hazard. We recommend that all tool service be performed

by a WEN Service Center.

CLEANING

Keep the planer clean of any wood chips, dust, dirt or debris. Ventilation openings and switch levers must be kept

clean and free of foreign matter. The tool may be cleaned most effectively with compressed dry air. Always wear

safety goggles when cleaning tools with compressed air. Do not attempt to clean these components by inserting

pointed objects through openings.

WARNING! Certain cleaning agents and solvents damage plastic parts. Some of these are: gasoline, carbon

tetrachloride, chlorinated cleaning solvents, ammonia and household detergents that contain ammonia.

CARBON BRUSHES

To maintain maximum efficiency of the motor, we recommend

changing the carbon brushes every 60 hours of operation. Replace-

ment carbon brushes (Model 6534-047) are available at wenprod-

ucts.com. Only genuine WEN replacement brushes designed spe-

cifically for your tool should be used. To inspect or replace the

carbon brushes:

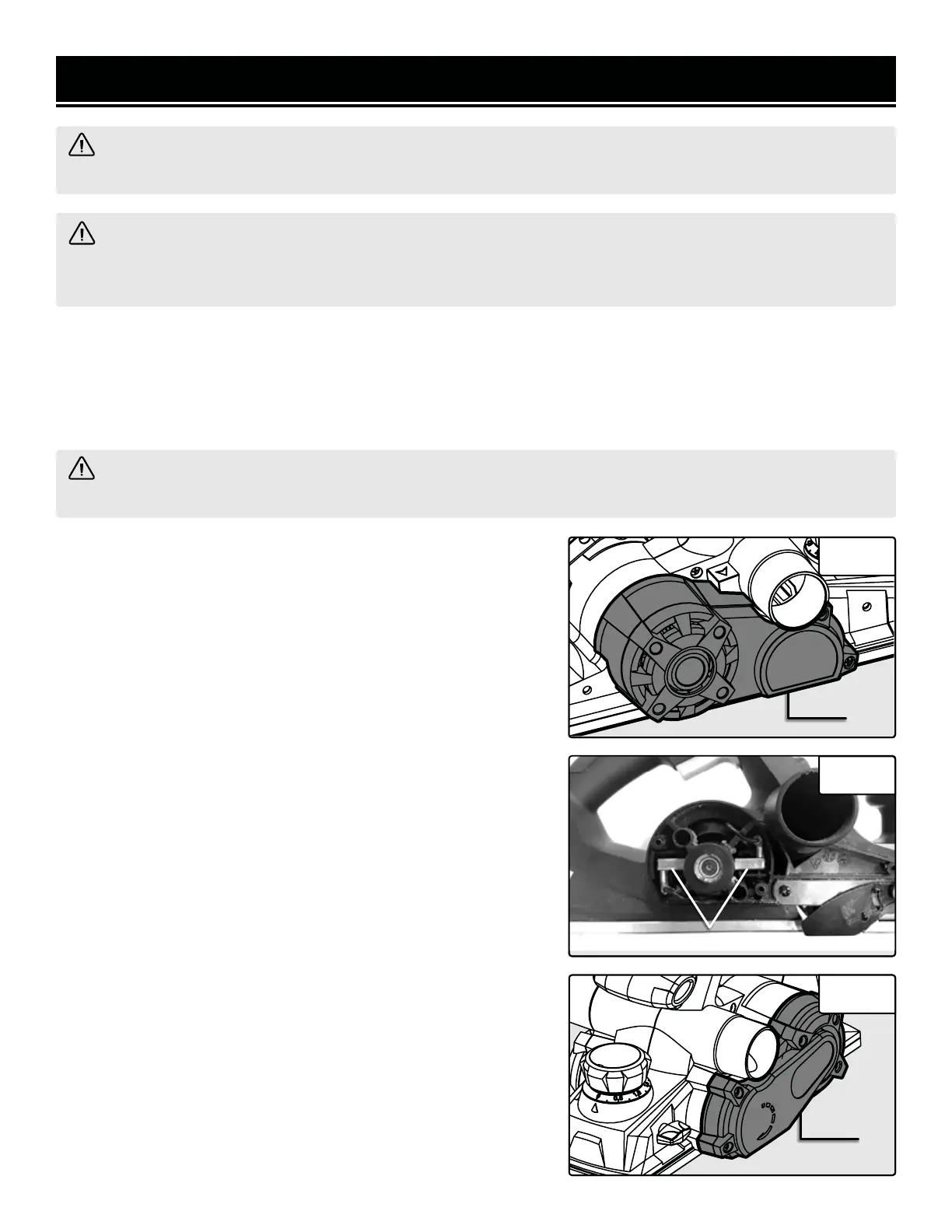

1. Unscrew and open the motor cover (Fig. 15 - 1) on the right.

2. Carefully take out the two carbon brushes (Fig. 16 - 1) using pli-

ers and replace with new brushes.

3. Replace the motor cover and secure with screws.

TOOL LUBRICATION

Your tool has been properly lubricated and is ready to use. It is rec-

ommended that tools with gears be regreased with a special gear

lubricant at every carbon brush change.

DRIVE BELT

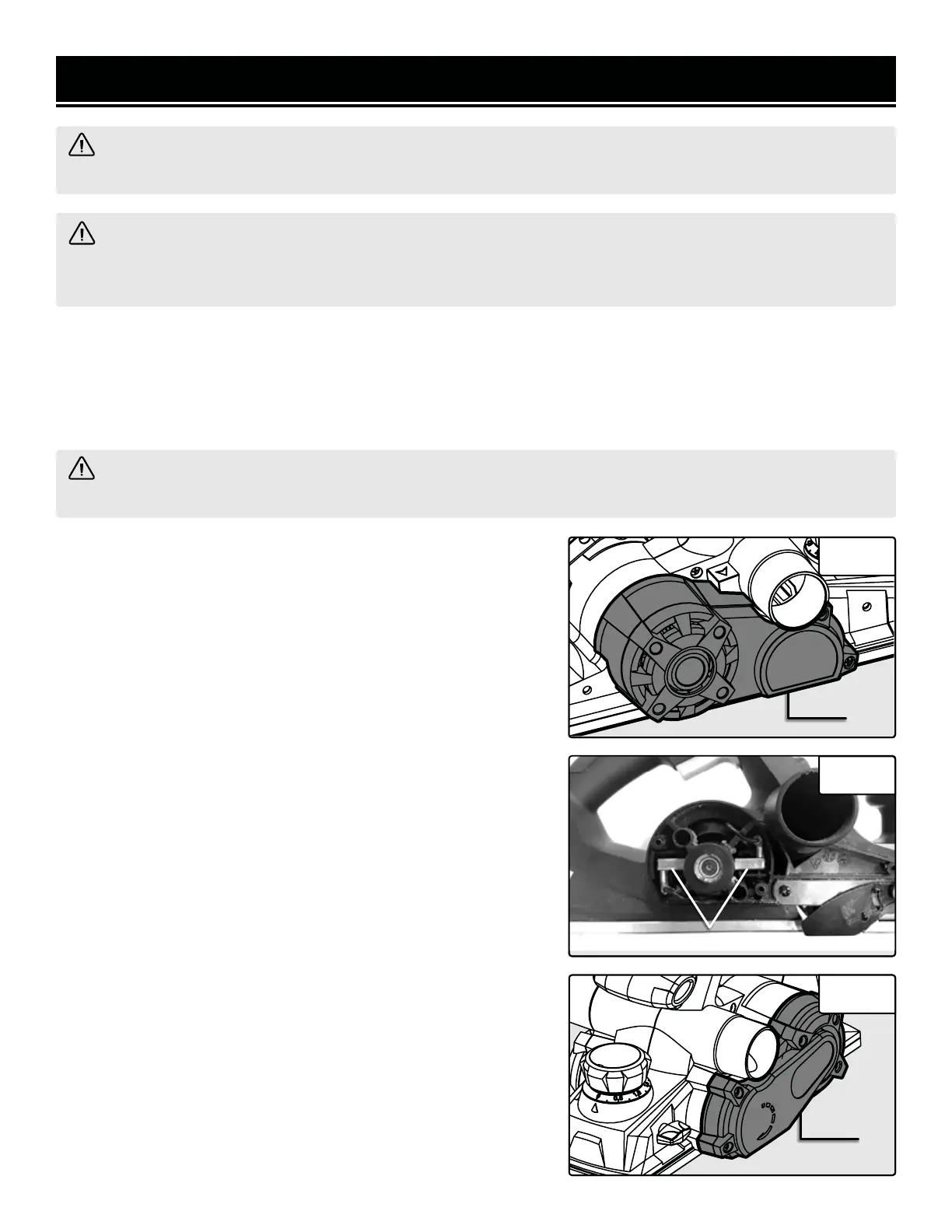

Inspect the drive belt every 60 hours of use. If the drive belt shows

signs of drying out, cracking, tearing or improper tracking, it should

be replaced. To replace the drive belt, unscrew and open the belt

cover (Fig. 17 - 1) on the left. Replace with identical replacement

belt and close the drive belt cover.

BEARINGS

Bearings that become noisy (due to heavy load or abrasive material

cutting) should be replaced by a qualified technician as soon as

possible to avoid overheating or motor failure.

Fig. 15

Fig. 16

Fig. 17

1

1

1

16

Loading...

Loading...