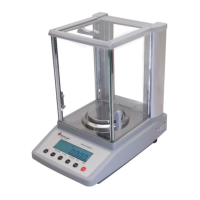

This document describes the WENSAR High Precision Balance, models HPB201, 501, and 1001 (Upgraded, with Internal Calibration). It is an analytical balance designed for laboratory, industrial, and commercial use, offering a wide range of functions including weighing, piece counting, and density determination. The balance incorporates electromagnetic force compensation technology for high precision, sensitivity, and rapid response time.

Function Description

The primary function of the balance is to determine the weighing value of materials. It operates as a "non-automatic" balance, requiring manual placement of material on the weighing plate. Once a stable weighing value is reached, it can be read from the display.

Key functions include:

- Weighing: Standard weighing in various units.

- Tare Function: Allows for the subtraction of container weight, enabling net weight determination. This can be repeated for multiple components in add-on weighing.

- Piece Counting: Determines the number of parts based on a calculated average piece weight, with higher reference quantities leading to greater accuracy.

- Density Determination (Hydrostatic Weighing): Calculates the density of solid and liquid samples using Archimedes' principle. For solids, the object is weighed in air and then in a measuring liquid. For liquids, a glass sinker with known volume is weighed in air and then in the liquid.

- Internal Calibration: The balance features an automatic internal calibration mechanism. It initiates calibration if the ambient temperature changes by more than 1.5 degrees Celsius or if the last calibration was more than 3 hours ago, ensuring consistent accuracy. Manual internal calibration can also be initiated.

- Data Output: An integrated RS-232 interface allows for automatic transmission of weighing data to a PC or printer.

- Zeroing Searches: Automatically finds the zero point.

Important Technical Specifications

The HPB series balances are 3-digit precision instruments.

| MODEL |

HPB201 |

HPB501 |

HPB1001 |

| Capacity |

220 g |

520 g |

1020 g |

| Pan Size |

90 mm Ø |

120 mm Ø |

|

| Readability |

0.001 g (1mg) |

|

|

| Repeatability (±) |

0.001 g |

|

|

| Calibration |

Internal Calibration |

|

|

| Make |

WENSAR |

|

|

| Linearity (±) |

± 0.002 g |

|

|

| Min. (Capacity) |

0.1 g |

|

|

| Display |

LCD |

|

|

| Response Time |

4 Sec |

|

|

| Tare Range |

Full |

|

|

| Operating Temperature |

15°C to 30°C |

|

|

| Density |

Yes |

|

|

| Unit |

mg, g, ct, ozt, oz, GN, dwt, lb |

|

|

| Key Sound |

Yes |

|

|

| Weighing Chamber Height |

195 mm |

|

|

| Baudrate |

1200, 2400, 4800, 9600 |

|

|

| Class |

I |

|

|

| Interface |

RS232C |

|

|

| Data Output Mode |

Command and continuos Output |

|

|

| Power Supply |

AC 220V / 50-60 Hz |

|

|

| Dimension (LxWxH) mm |

220 x 360 x 345 mm |

|

|

| Weight |

10 kg |

|

|

An optional Density Determination Kit for solid & liquid samples is available, with manual calculation.

Usage Features

- Display: Large LCD display with backlight, digit height 15 mm.

- Weighing Units: Supports 7 units: grams (g), carats (ct), troy ounces (ozt), ounces (oz), grains (GN), pennyweights (dwt), and milligrams (mg).

- Underfloor Weighing: Allows weighing of objects unsuitable for placement on the pan due to size or shape, using a hook suspended from the balance bottom.

- Adjustable Feet and Level Indicator: Four adjustable feet and a spirit level ensure horizontal placement for accurate measurements.

- Wind Protection: Features a glass wind protection shell.

- Removable Pan: A stainless steel pan that can be easily cleaned.

- Setting Menu: Allows configuration of various parameters such as sensitivity, filtering strength, serial port transmission speed, device number for communication, backlight mode, and internal calibration function. Factory settings are optimized for common use.

- Factory Reset: Option to restore all parameters to default settings.

Precautions and Proper Use:

- Environmental Conditions: Use indoors only, within specified temperature and humidity ranges (15°C to 30°C). Avoid high temperature fluctuations, strong airflows, vibrations, dust, and extreme humidity.

- Stability: Place the balance on a stable, level surface.

- Overload Protection: Do not overload the balance beyond 20% of its maximum capacity. Avoid impacts and permanent loads on the weighing plate.

- Explosive Environments: Not designed for use in explosive environments.

- Power Supply: Use only the original supplied mains power cord and ensure the correct voltage. If the power cable is damaged, it must be replaced by authorized personnel.

- Warm-up Time: A warm-up time of at least 1 hour is required after initial setup or relocation to allow the balance to adapt to ambient temperature.

- Modifications: Do not modify the balance structure.

- Static Charge: Avoid static charge of goods or containers being weighed.

- Electromagnetic Interference: Be aware of potential weighing deviations caused by electromagnetic fields (e.g., mobile phones) or static electricity. Change location or remove sources of interference if issues occur.

Maintenance Features

- Cleaning: Disconnect from power supply before cleaning. Use a cloth dampened with mild soap suds. Do not use aggressive cleaning agents (solvents) and ensure no liquid penetrates the device. Wipe with a dry, soft cloth.

- Residue Removal: Loose residue or powder can be removed with a brush or manual vacuum cleaner. Spillages should be removed immediately.

- Repair: Only trained service technicians authorized by the manufacturer should open the appliance for repairs. Always disconnect from power supply before opening.

- Quality Assurance: Regular checks of the balance's measuring properties and adjusting weights are recommended as part of quality assurance. The user is responsible for defining the interval and scope of these tests.

The balance is built with a standard weight and a precision automatic loading device, controlled by a computer mechanism, to ensure easy, fast, and automatic operation for optimal results.