Do you have a question about the Westerbeke 3.5 MCGA 60 Hz and is the answer not in the manual?

Guide to quickly get started by referring to key sections of the manual for operation and maintenance.

Information on the operator manual and associated installation manual, available online and for order.

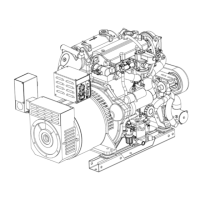

Visual identification of key engine and generator components for easy reference.

Steps for registering the product and understanding Westerbeke's warranty coverage.

Precautions for avoiding electrical hazards when working with the generator and its components.

Steps to prevent unintended engine starts during maintenance or servicing.

Warnings about touching hot engine parts and exhaust systems to prevent burns.

Safety measures to prevent fuel-related fires and explosions near the engine.

Precautions regarding highly explosive fuel vapors and safe handling.

Safety guidelines for handling batteries, preventing explosions and acid exposure.

Information on carbon monoxide hazards and the importance of ventilation and detectors.

Warnings about the dangers of rotating engine components and safe servicing practices.

Information on potential hearing damage from generator noise and proper muffler use.

Compliance requirements with ABYC, NFPA, and USCG standards for marine installations.

Details on CO emissions, reduction strategies, and safety monitoring for EFI generators.

Compliance requirements with federal, ABYC, Coast Guard, and NFPA safety codes for marine installations.

Recommendation to mount carbon monoxide detectors in all living quarters on the vessel.

Necessity of installing a siphon-break for exhaust systems near the vessel waterline.

Design criteria for exhaust systems to prevent water entry and use of marine-certified hose.

Instructions for installing the optional remote oil filter kit for relocating the engine oil filter.

Specifies unleaded gasoline with an octane rating of 89 or higher, cautioning against E-15 fuel.

Importance of clean fuel and proper fuel system components like filters and separators.

Recommendations for engine oil type, API/SAE designations, and oil/filter change intervals.

Details on recommended coolant mixture (50/50 antifreeze/distilled water) and its function.

Function and recommended placement of the coolant expansion tank.

Procedure for removing air from the fuel system (priming) before initial start or after service.

Instructions for starting and stopping the generator using the control panel or remote panels.

Explanation of safety features and fault indicators that automatically shut down the generator.

Guidelines for breaking in the generator during the first 10 hours of operation.

Pre-start checks before the first operation or after a long period of inactivity.

Daily checks to perform before starting the generator to ensure proper operation.

Defines intervals for maintenance tasks based on operating hours or time, including daily, 50hr, 100hr, 250hr, 500hr, 1000hr, and 2000hr intervals.

Maintenance tasks recommended every 50 operating hours or monthly.

Maintenance tasks recommended every 100 operating hours or yearly.

Maintenance tasks recommended every 250 operating hours or yearly.

Maintenance tasks recommended every 500 operating hours or yearly.

Maintenance tasks recommended every 500 operating hours or every two years.

Maintenance tasks recommended every 1,000 operating hours or every five years.

Maintenance tasks recommended every 2,000 operating hours.

Details on fuel system components, filters, pumps, and procedures for maintenance.

Procedures for draining, refilling, and maintaining the engine's cooling system.

Maintenance of the zinc anode in the raw water cooling circuit for electrolysis protection.

Inspection and maintenance of the coolant thermostat to control engine temperature.

Procedure for cleaning the raw water intake strainer to ensure adequate cooling water flow.

Information on the raw water pump, its impeller, and maintenance procedures.

Step-by-step guide to changing the raw water pump impeller for proper cooling.

General engine maintenance procedures including oil, filters, spark plugs, and pressure checks.

Detailed steps for safely removing and replacing the engine oil filter.

Procedure for adding fresh engine oil to the correct level on the dipstick.

Inspection and maintenance of spark plugs for proper engine operation and emissions control.

Cleaning and inspection of the air screen and flame arrestor for engine air intake.

Monitoring engine oil pressure and troubleshooting low pressure fault conditions.

Information on the battery charger circuit and its function during generator operation.

Guidelines for checking and maintaining the generator's starting battery.

Maintenance of the exhaust system catalyst for minimizing engine CO exhaust emissions.

Ensuring clean connections and proper function of motors and circuit breakers.

Considerations for starting electric motors with the generator, including starting current.

Procedures for testing the generator under different load conditions to ensure proper operation.

Overview of the single-phase BC generator's operation and output.

Function and operation of the AC circuit breaker for overload protection.

Wiring diagram for AC terminal connections of the BC generator for different voltage/frequency.

Installation and use of a shore power transfer switch to prevent simultaneous connections.

Using diagnostic software with a USB cable to monitor engine and ECU functions and record data.

A chart listing common engine problems and their potential causes for diagnosis.

Wiring diagrams for remote start/stop panel installations with fault display or rocker switch.

Steps for preparing the lubrication system for storage, including oil and filter change.

Procedures for ensuring batteries are fully charged or removed for storage.

Lubricating engine cylinders with fogging oil for protection during storage.

Preparing the fuel system for seasonal storage, including fuel stabilizer and filter checks.

Lubrication and cleaning of the starter drive pinion during lay-up.

Preparing the raw water cooling circuit for storage using an antifreeze mixture.

Cleaning the intake manifold and flame arrestor for storage.

Opportunity to inspect engine components and order necessary spare parts during lay-up.

Steps to prepare the engine for operation after a period of storage.

Detailed technical specifications of the generator's engine, including type, displacement, and power.

Technical details of the generator's fuel system, including source, consumption, and filters.

Technical specifications of the generator's electrical system, including battery and starter requirements.

Airflow requirements for engine and generator cooling, and maximum ambient operating temperature.

Technical specifications for the engine's fresh water and raw water cooling systems.

Technical specifications for the engine's lubrication system, including oil capacity and pressure.

Technical ratings and specifications for the single-phase AC generator output.

Technical details of the generator's ignition system, including spark plug gap and timing.

Torque values for various engine components to ensure proper assembly and function.

| Model | 3.5 MCGA |

|---|---|

| Frequency | 60 Hz |

| Power Output | 3.5 kW |

| AC Voltage | 120V |

| Fuel Type | Gasoline |

| Cooling System | Air Cooled |

| Phase | Single Phase |

| Starting System | Electric |