Do you have a question about the Westerbeke 12.5 BTDA and is the answer not in the manual?

Details the dangers of carbon monoxide poisoning and its symptoms.

Emphasizes reading the manual and following fundamental safety rules.

Precautions to avoid electrical hazards during operation and maintenance.

Warnings about touching hot engine parts and exhaust systems.

Safety measures to prevent flash fires and fuel-related ignition.

Guidelines to prevent explosions from fuel vapors.

Covers risks of accidental starting, battery explosion, and acid hazards.

Information on carbon monoxide and diesel exhaust hazards.

Warning about injury risks from rotating engine components.

Advice on clothing, jewelry, and general safe practices.

References ABYC, NFPA, and USCG publications for installation guidelines.

Highlights need to comply with federal, ABYC, and safety codes.

Details the requirement and function of a siphon-break for exhaust systems.

Specifies marine-certified hose and design for preventing water entry.

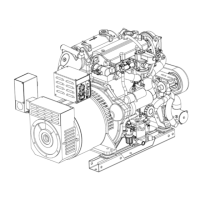

Introduction to Westerbeke diesel generators and manual's purpose.

Steps for registering warranty and obtaining customer identification.

Defines the meaning of Notes, Cautions, and Warnings in the manual.

Westerbeke's disclaimer regarding third-party product software.

Six key steps for ensuring long generator life and proper maintenance.

Identifies locations for engine and generator serial numbers on the unit.

Recommends installing CO detectors for vessel safety.

Basic principles and differences of diesel engines compared to gasoline.

Information on providing correct details for ordering replacement parts.

Guidance on obtaining necessary spare parts and accessories.

Mentions the availability of a separate installation manual.

Details required diesel fuel grade and best practices for fuel supply.

Specifies engine oil type, API classification, and change schedule.

Advises on coolant mixture, type, and maintenance for engine longevity.

Explains the purpose and placement of the coolant recovery tank.

Describes the functions of Preheat, Start, and Stop switches.

Explains the readings and purpose of various gauges on the control panel.

Details the use of the optional remote start/stop panel.

Essential checks before starting the generator for the first time or after layoff.

Verification of factory settings for generator voltage and frequency.

Describes High Exhaust Temp, Low Oil Pressure, and Coolant Temp switches.

Details the 20 Amp DC circuit breaker and its role in protecting the system.

Explains the electric starter and glow plug system for ignition.

Steps to take if the engine fails to start, including caution on cranking.

Instructions for operating the generator remotely.

Steps to safely shut down the generator after operation.

Explains the 50-hour break-in period for engine longevity and performance.

Guidance on monitoring gauges, checking leaks, and varying load.

Notes on potential adjustments for engine speed (hertz) during break-in.

Routine checks including coolant, oil, fuel, and visual inspection.

Specific maintenance tasks required during the first 50 operating hours.

Regular tasks like drive belt, battery, and zinc anode checks.

Tasks for 250 hours/yearly: exhaust, fuel filters, hoses, impeller, alternator.

Tasks for 500 hours/five years: raw water pump, coolant, valve clearances.

Tasks for 1000 hours/five years: heat exchanger, glow plugs.

Explains the fresh water and raw water cooling circuits.

Details the flow of coolant through the engine and heat exchanger.

Explains the purpose and placement of the coolant recovery tank.

Procedure for draining, flushing, and refilling the engine coolant.

Instructions for changing the raw water pump impeller.

Procedure for cleaning the raw water intake strainer.

Description of the heat exchanger's function in cooling.

Steps for refilling the engine coolant after draining or servicing.

Procedure for replacing the engine thermostat and gasket.

Details on the raw water pump and impeller care.

Explains the purpose of zinc anodes and how to replace them.

Procedure for cleaning and pressure testing the heat exchanger.

Describes the function and minimal maintenance of the air intake silencer.

Specifies the type and grade of diesel fuel required for the engine.

Overview of the fuel flow from tank to injectors.

Illustrates the typical fuel system layout.

Emphasizes the importance of the primary fuel filter/water separator.

Details the secondary fuel filter and its replacement schedule.

Step-by-step guide for replacing the fuel filter element.

Describes the function and types of fuel lift pumps used.

Detailed steps for draining oil and replacing the oil filter.

Explains normal oil pressure ranges and factors affecting it.

Information on low oil pressure readings and potential causes.

Method for testing oil pressure using a mechanical gauge.

Overview of the DC charging system components.

Steps to diagnose issues with the alternator or charging circuit.

Procedure for testing alternator output voltage while the engine runs.

Procedure for checking the service battery voltage and charging.

Reference to wiring diagrams for the 12V DC control circuit.

Details recommended battery capacity and essential care practices.

Components and types of the starter motor used.

General guidance on starter adjustment and repair.

Procedure for checking and adjusting the starter pinion gap.

Steps for testing the starter motor's performance without load.

Procedure for testing the starter solenoid's continuity and operation.

Step-by-step instructions for disassembling the starter motor.

How to inspect, test, and install glow plugs.

Guidance on checking and servicing fuel injectors.

Procedure for adjusting engine speed to set generator frequency.

Steps for properly tensioning the drive belts for alternator and pump.

Procedure for adjusting valve clearance for specific models.

Procedure for adjusting valve clearance for specific models.

Guidance on starting motor current requirements and generator capacity.

How engine speed affects generator frequency (Hz).

Importance of cleanliness, connections, and inspecting for damage.

Installation and use of the optional solid-state voltage regulator.

Cautionary advice on safely switching between power sources.

Guide for diagnosing common generator AC voltage output issues.

Procedure for adjusting voltage output without load using shims.

Method for fine-tuning voltage output under load by repositioning wires.

Detailed steps to change generator frequency by adjusting engine speed.

Diagrams for configuring AC output connections for different voltages/hertz.

Explains terminal connections for the 3-phase voltage regulator.

Illustrates connection points for parallel WYE, series WYE, and series DELTA.

Diagrams for connecting shore power using the transfer switch.

Safety precautions when transferring between power sources.

Details the specific wiring for a 120V/60Hz three-wire system.

Step-by-step guide for starting and stopping the generator.

Detailed procedure for starting and stopping the engine.

Important notes regarding circuit breakers and starter circuit safety.

Instructions for installing the optional remote oil filter kit.

Description of the PTO adapter for engine power utilization.

Covers general procedures for preparing the craft for lay-up.

Advice on opening couplings for boats hauled out of water.

Recommendations for antifreeze concentration during winter.

Instructions for draining oil and replacing the filter before storage.

Steps for fuel stabilization and maintenance for diesel engines during lay-up.

Procedure for flushing the raw water circuit with antifreeze.

Methods to protect intake and exhaust ports during storage.

Advice on starter motor lubrication and cleaning before lay-up.

Procedure for lubricating cylinders using Marvel Mystery Oil.

Steps to protect the flame arrester and exhaust port for gasoline engines.

Procedure for fogging cylinders with oil for gasoline engines.

Guidelines for storing batteries to prevent freezing and maintain charge.

Advice on checking transmission fluid and protecting coupling.

Suggestions for checking and stocking spare parts.

Steps to prepare the engine for operation after lay-up.

| Model | 12.5 BTDA |

|---|---|

| Power Output | 12.5 kW |

| Fuel Type | Diesel |

| Starting System | Electric Start |

| AC Voltage | 120/240V |

| AC Frequency | 60 Hz |

| Alternator | Brushless |

| Engine Type | Diesel, 4-cycle |

| RPM | 1800 RPM |

Loading...

Loading...