Do you have a question about the Westerbeke 5.5KW EDC 60HZ and is the answer not in the manual?

Overview of manual structure, safety precautions, and notation for notes, cautions, and warnings.

Safety guidelines for preventing electric shock, burns from hot engine parts, fire, and explosion.

Safety procedures for accidental starting, avoiding moving parts, and mitigating hazardous noise.

Precautions regarding battery explosions, acid hazards, and dangers of toxic exhaust gases like carbon monoxide.

Compliance requirements for installing engines and generators in a marine environment.

Instructions for installing a siphon-break in the raw water supply hose to prevent flooding.

Guidelines for ensuring the exhaust system prevents water entry and is certified for marine use.

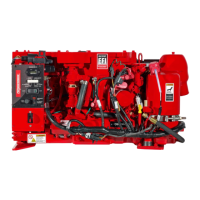

Diagram illustrating the location of key components of the 5.5KW generator.

Explanation of NOTES, CAUTIONS, and WARNINGS used throughout the manual.

Information on locating serial numbers and understanding the diesel engine's basic principles.

Guidance on providing correct information when ordering spare parts and accessories.

Specifications for diesel fuel quality, care of fuel supply, and filter recommendations.

Guidelines for selecting and changing engine oil, including API classification and viscosity.

Recommendations for coolant mixture, maintenance, and the function of the coolant recovery tank.

Essential checks to perform before starting the generator for the first time or after a long layoff.

Procedure for conditioning new engines to maximize performance and service life over the first 50 hours.

A daily checklist to ensure proper operation and identify potential issues before starting the generator.

Proper procedure for shutting down the generator, including load removal and safety precautions.

Overview of the digital control panel's LCD display, indicator lights, and operational sequences.

Details on scroll lock, arrow controls for contrast, fuel priming, and LCD display maintenance.

Step-by-step instructions for starting and stopping the generator using the control panel.

How the panel indicates failures, common error messages, and procedures for restarting.

Guidance on diesel fuel, fuel filters, and the fuel water separator for system cleanliness.

Information on the fuel injection pump's importance and the caution against self-servicing.

Maintenance checks for fuel lift pump connections and the inlet fuel filter.

Description of the fresh water and raw water cooling circuits and their interaction.

Details on the fresh water coolant circulation, thermostat function, and coolant passages.

Procedure for changing coolant, maintaining the recovery tank, and air intake cooling.

Maintenance for the thermostat and raw water intake strainer, including cleaning and inspection.

Step-by-step guide for draining oil, replacing the oil filter, and refilling the oil sump.

Instructions for installing an optional accessory to relocate the engine's oil filter.

Details on the starter motor's type, mechanism, and typical configuration.

Procedures for diagnosing starter motor faults, emergency starting, and general service information.

Detailed technical specifications for the generator's engine, including dimensions and performance data.

Specifications for the generator's electrical system, cooling, lubrication, and AC output.

Specifications related to the fuel system, tune-up parameters, and exhaust emissions.

Schematic diagram illustrating the generator's electrical wiring connections.

Procedure for checking and adjusting drive belt tension to ensure proper operation.

Guidelines for torquing cylinder head bolts and servicing fuel injectors.

Procedures for adjusting generator frequency via engine speed and electronic governor settings.

Instructions for adjusting valve clearances and testing engine cylinder compression.

Procedure for setting the injection pump timing (spill timing) for optimal engine performance.

Methods for testing oil pressure and the functionality of glow plugs.

Detailed steps for removing, inspecting spray patterns, and testing fuel injectors.

Overview of the charging system and initial checks before testing the alternator.

Procedures for testing the alternator's voltage output and charging capabilities.

Testing the alternator's excitation circuit, service battery, and battery care recommendations.

Guidance on installing and connecting the shore power transfer switch for safe operation.

Information on current requirements for starting electric motors and generator capacity.

Procedures for adjusting generator frequency and performing routine generator maintenance.

Overview of the BC generator, its self-exciting nature, and the role of the circuit breaker.

Instructions for adjusting no-load voltage for single and dual exciter models.

Steps for preparing the engine, cylinders, intake, batteries, and transmission for storage.

Procedures for recommissioning the engine after storage, including spare parts.

General advice for lay-up of cooling, lubrication, and fuel systems, and intake/exhaust.

Information on attaching a power take-off adapter to utilize engine power for accessories.

Details on available spare parts kits for basic and extensive off-shore cruising needs.

| Power Output | 5.5 kW |

|---|---|

| Frequency | 60 Hz |

| Fuel Type | Diesel |

| Starting System | Electric Start |

| AC Voltage | 120/240V |

| Phase | Single Phase |

| Model | 5.5KW EDC |

| Cooling System | Water-cooled |

| Fuel Consumption | 0.5 gph |

| Engine Type | 4-cycle diesel |

Loading...

Loading...