Do you have a question about the Westerbeke 12.5 BTD and is the answer not in the manual?

Provides an overview of the manual's purpose and general safety precautions.

Details precautions to avoid electrical hazards when operating the generator.

Warns about hot engine parts and exhaust systems, advising caution.

Outlines measures to prevent flash fires near fuel sources and hot components.

Advises on preventing explosions from fuel vapors, especially during fueling.

Describes procedures to prevent unintended engine starts and associated risks.

Warns about the dangers of battery explosions due to hydrogen gas.

Advises on handling battery acid safely, warning of corrosive properties.

Explains the dangers of carbon monoxide and other exhaust gases.

Highlights the risks associated with rotating engine components.

Discusses risks of hearing loss from noise and proper muffler use.

Lists publications for safety codes and standards relevant to marine installations.

Stresses compliance with federal, ABYC, and safety codes for marine environments.

Explains the necessity and function of a siphon-break in the raw water supply hose.

Details requirements for marine-certified exhaust hoses and system design.

Guides users on warranty registration and obtaining a customer identification card.

Explains the meaning of NOTE, CAUTION, and WARNING labels in the manual.

Disclaimer regarding third-party product software and its reliability.

Offers six steps to ensure long generator life and dependable service.

Details where to find the engine and generator serial and model numbers.

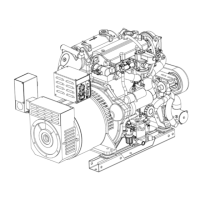

Compares diesel engines to gasoline engines and highlights key differences.

Instructs on providing correct information when ordering replacement parts.

Recommends stocking essential spare parts and lists available accessories.

Refers to the separate installation manual publication #043268.

Specifies the required diesel fuel grade and additives for optimal performance.

Details the recommended engine oil type and change intervals for maintenance.

Recommends coolant mixture and highlights the role of antifreeze.

Guides selection of diesel-specific antifreeze and pre-mixed varieties.

Specifies changing engine coolant every five years regardless of hours.

Explains the function of the coolant recovery tank for expansion and contraction.

Details the functions of the PREHEAT, START, and STOP toggle switches.

Explains the readings of the Coolant Temperature, Oil Pressure, DC Voltmeter, and Hourmeter.

Describes the operation of remote control panels and their wiring.

Lists critical checks before starting the generator for the first time or after a layoff.

Advises on verifying and adjusting generator output voltage and frequency.

Explains the three automatic switches protecting the engine from shutdown.

Details the function of the switch that monitors engine oil pressure.

Describes the switch that monitors exhaust temperature and triggers shutdown.

Explains the switch that monitors engine coolant temperature.

Details the engine's DC circuit protection via a 20 Amp breaker.

Explains the diesel starting system using glow plugs and electric starters.

Provides troubleshooting steps if the engine fails to start after cranking.

Describes how to start the generator using a remote panel.

Details the correct steps to stop the generator using the STOP switch.

Explains how to stop the generator from a remote panel.

Explains the importance of break-in for engine service life and seating piston rings.

Lists items to monitor during the break-in period, including noise and smoke.

Mentions potential adjustments for engine speed (hertz) and voltage during break-in.

Introduces the maintenance schedule and details of tasks.

Lists essential checks performed daily before starting the engine.

Outlines specific maintenance tasks required during the first 50 operating hours.

Details maintenance tasks to be performed every 50 hours or monthly.

Lists maintenance tasks for every 100 operating hours or annually.

Specifies maintenance for every 250 operating hours or annually.

Outlines maintenance for 500 operating hours or every five years.

Details maintenance for 1000 operating hours or every five years.

Explains the fresh water and raw water cooling systems of the marine diesel engine.

Details the path of the circulating fresh water coolant through the engine.

Describes the function and location of the coolant recovery tank.

Provides instructions and cautions for draining and refilling the engine coolant.

Guides on replacing the raw water pump impeller, noting potential issues.

Explains the importance of a clean strainer and its maintenance.

Describes the heat exchanger's function in transferring heat from fresh to raw water.

Details the process of refilling the coolant after maintenance, including bleeding.

Guides on removing, replacing, and installing the engine thermostat.

Summarizes the flow of raw water for cooling and exhaust gas mixing.

Explains the operation of the raw water pump and the importance of lubrication.

Describes the purpose and maintenance of the zinc anode in the cooling circuit.

Recommends periodic cleaning and pressure testing of the heat exchanger.

Explains the function of the silencer and its minimal maintenance requirements.

Specifies fuel requirements, including grade and additives, and the importance of cleanliness.

Outlines how fuel is drawn, pressurized, and delivered to the injectors.

Refers to a typical diagram of the fuel system components.

Emphasizes the need for a primary filter/water separator to prevent fuel contamination.

Details the replacement interval for the engine-mounted fuel filter.

Provides step-by-step instructions for changing the fuel filter element.

Describes the two types of fuel lift pumps and their operation.

Details the process for changing the engine oil and filter, including cautions.

Explains the lubricating system and normal oil pressure ranges.

Discusses low oil pressure symptoms and their potential causes.

Guides on testing oil pressure using a mechanical gauge.

Describes the components of the DC charging system, including the alternator and regulator.

Provides guidance for troubleshooting common alternator and charging circuit issues.

Outlines procedures for testing the alternator's output voltage while the engine is running.

Explains how to check the service battery voltage for proper charging.

Refers to wiring diagrams for the engine's 12-volt DC control circuit.

Specifies the recommended capacity for the engine's 12-volt DC control circuit battery.

Provides essential tips for maintaining the starting and house batteries.

Describes the components of the starter motor, including its internal reduction design.

Guides on starter adjustment and identifies potential repair needs.

Details how to inspect and adjust the pinion gap on the starter.

Explains how to perform a no-load test on the starter motor.

Describes testing procedures for the starter motor's solenoid assembly.

Describes testing the solenoid's attraction pull.

Details testing the solenoid's ability to hold the pinion in place.

Explains how to test the solenoid's return function.

Notes that Westerbeke uses standard starter motors serviceable at service centers.

Provides steps for disassembling the starter motor for inspection and repair.

Explains the function, inspection, and testing of glow plugs.

Guides on inspecting glow plug tips and threads for wear and deposits.

Details methods for testing glow plug resistance and power drain.

Advises on checking and overhauling fuel injectors, recommending professional service.

Explains how engine speed affects generator frequency and how to adjust it.

Details the process of adjusting drive belt tension to ensure proper charging and longevity.

Provides instructions and torque specifications for adjusting valve clearance.

Details valve clearance adjustment for 8.0KW & 10.0KW BTD models.

Lists general engine and operating specifications.

Provides detailed specifications for the fuel system components.

Details specifications for the engine's oil filter, sump capacity, and oil grade.

Lists specifications for the starting battery, alternator, and starter.

Provides specifications for the cooling system, including temperatures and pump types.

Mentions emission control systems like smoke puff limiters.

Lists AC generator specifications for single-phase output.

Lists AC generator specifications for three-phase output.

Details air requirements and temperature recommendations for generator cooling.

Lists general engine and operating specifications.

Provides detailed specifications for the fuel system components.

Details specifications for the engine's oil filter, sump capacity, and oil grade.

Lists specifications for the starting battery, alternator, and starter.

Provides specifications for the cooling system, including temperatures and pump types.

Mentions emission control systems like smoke puff limiters.

Lists AC generator specifications for single-phase output.

Lists AC generator specifications for three-phase output.

Details air requirements and temperature recommendations for generator cooling.

Lists general engine and operating specifications.

Provides detailed specifications for the fuel system components.

Details specifications for the engine's oil filter, sump capacity, and oil grade.

Lists specifications for the starting battery, alternator, and starter.

Provides specifications for the cooling system, including temperatures and pump types.

Mentions emission control systems like smoke puff limiters.

Lists AC generator specifications for single-phase output.

Lists AC generator specifications for three-phase output.

Details air requirements and temperature recommendations for generator cooling.

Lists general engine and operating specifications.

Provides detailed specifications for the fuel system components.

Details specifications for the engine's oil filter, sump capacity, and oil grade.

Lists specifications for the starting battery, alternator, and starter.

Provides specifications for the cooling system, including temperatures and pump types.

Mentions emission control systems like smoke puff limiters.

Lists AC generator specifications for single-phase output.

Lists AC generator specifications for three-phase output.

Details air requirements and temperature recommendations for generator cooling.

Discusses starting current requirements for electric motors and generator capacity.

Explains how engine speed affects generator frequency and how to adjust it.

Covers routine cleaning, connection checks, and bearing inspection for the generator.

Describes the optional solid-state voltage regulator for BT 6 stud models.

Warns about potential damage when switching power sources.

Lists common generator issues and corresponding component checks for diagnosis.

Provides resistance values for various components in the exciter circuit.

Lists nominal AC and DC voltages for the exciter circuit under different loads.

Details how to adjust generator voltage when no load is applied.

Explains how to adjust generator voltage under full load conditions.

Explains the relationship between engine speed and generator frequency.

Illustrates AC voltage connection configurations for 6-stud generators.

Illustrates AC voltage connection configurations for 12-stud generators.

Provides resistance values for exciter and stator windings, and transformer components.

Lists nominal AC and DC voltages for the exciter circuit.

Shows connection points and jumpers for three-phase generator configurations.

Illustrates wiring for connecting shore power to the vessel's AC circuit.

Warns about potential damage when switching power sources.

Guides on installing the optional remote oil filter kit, emphasizing correct line connections.

Describes the power take off adapter for utilizing engine power for accessories.

Outlines general procedures for preparing the engine for lay-up and recommissioning.

Advises on inspecting and protecting the propeller shaft coupling during lay-up.

Recommends maintaining antifreeze protection in the cooling system.

Details draining oil, replacing the filter, and checking pressure before lay-up.

Provides lay-up instructions for gasoline fuel systems, including stabilizer use.

Outlines lay-up procedures for diesel fuel systems, including additives and filter changes.

Instructs on flushing the raw water system with antifreeze for winter protection.

Advises on blocking intake and exhaust ports to prevent contamination.

Suggests lubrication and cleaning of the starter drive pinion.

Recommends squirting oil into cylinders for long lay-up periods.

Recommends using fogging oil for gasoline engine cylinder lubrication.

Provides guidance on battery storage and handling during lay-up.

Advises checking transmission fluid and protecting the coupling.

Suggests inspecting and ordering spare parts during lay-up.

Outlines steps to prepare the engine for operation after lay-up.

Lists common spare parts and recommended kits for Westerbeke diesel generators.

| Brand | Westerbeke |

|---|---|

| Model | 12.5 BTD |

| Category | Portable Generator |

| Language | English |

Loading...

Loading...