Do you have a question about the Westerbeke 10.0 BTD and is the answer not in the manual?

Safety precautions to avoid electrical hazards during operation and maintenance.

Warnings and guidelines to prevent burns from hot engine components.

Precautions to prevent explosions from fuel vapors.

Safety procedures to prevent unintentional engine starts.

Hazards and safety precautions related to battery explosions.

Information on the dangers of carbon monoxide and exhaust fumes.

Safety warnings regarding moving parts to prevent injury.

Information on noise hazards and protection measures.

Importance and installation of siphon breaks to prevent engine damage.

Checklist of essential checks before starting the generator for the first time.

Factory settings and verification of generator voltage and frequency.

Overview of automatic shutdown switches protecting the engine.

Troubleshooting steps for engine starting failures and potential damage.

Essential daily checks before operating the generator.

Maintenance tasks required during the first 50 hours of operation.

Maintenance tasks performed every 100 hours or annually.

Maintenance tasks performed every 250 hours or annually.

Steps for replacing the raw water pump impeller.

Procedure for changing the fuel filter element.

Step-by-step instructions for changing engine oil and filter.

Troubleshooting guide for alternator issues.

Procedures for testing the alternator's output and charging capability.

When to check injectors and their installation torque.

Adjusting engine speed to set generator frequency (50/60 Hz).

How to properly tension and adjust drive belts.

Procedure for adjusting valve clearance on specific models.

Procedure for adjusting valve clearance on specific models.

Troubleshooting guide for common BT generator issues.

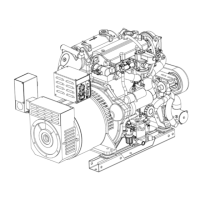

| Model | 10.0 BTD |

|---|---|

| Type | Portable Generator |

| Power Output | 10.0 kW |

| Fuel Type | Diesel |

| Starting System | Electric Start |

| AC Voltage | 120/240V |

| AC Output | 10, 000 Watts |

| Cylinders | 3 |

| Compression Ratio | 22:1 |

| Cooling System | Liquid Cooled |

| Lubrication System | Forced Lubrication |

| Voltage | 120/240V |

| Frequency | 60 Hz |

| Phase | Single Phase |

| Engine Type | 4-Cycle |

| Alternator | Brushless |

Loading...

Loading...