FUEL

SYSTEM

DIESEL

.filii.

Use a diesel

fuel

that meets the requirements of No.2-D SAE

J

313

and

has

a cetane rating

of

45

or higher according to

ASTMD975.

DESCRIPnON

Fuel is drawn into the engine's fuel system by the electric

fuel

pump mounted on the generator's drive engine. Fuel

is drawn from the fuel tank through the primary

fuel

filter/water separator through the

fuel

pump, then under

pressure

(6-8

psi) and delivered

to

the secondary

fuel

fi,lter

mounted on the engine. Fuel passes through this filter

to

the

fuel injection pump where the injection pump delivers it

to

the mjectors, The fuel serves three purposes in the system. It

is

used for combustion, lubrication and carries heat away

from the injection equipment through the return back

to

the

fuel

tank where it

is

dissiPated in the cool fuel in the

tank.

FU~L

SYSTEM

DIAGRAM

(TYPICAL)

FOB.

SYSTEM

All

WESTERBEKE

ENGINE/GENERATOR

INSTALLATIONS

REQUIRE

AN

OWNER-INSTALLED

FUELJWATER

SEPARATOR

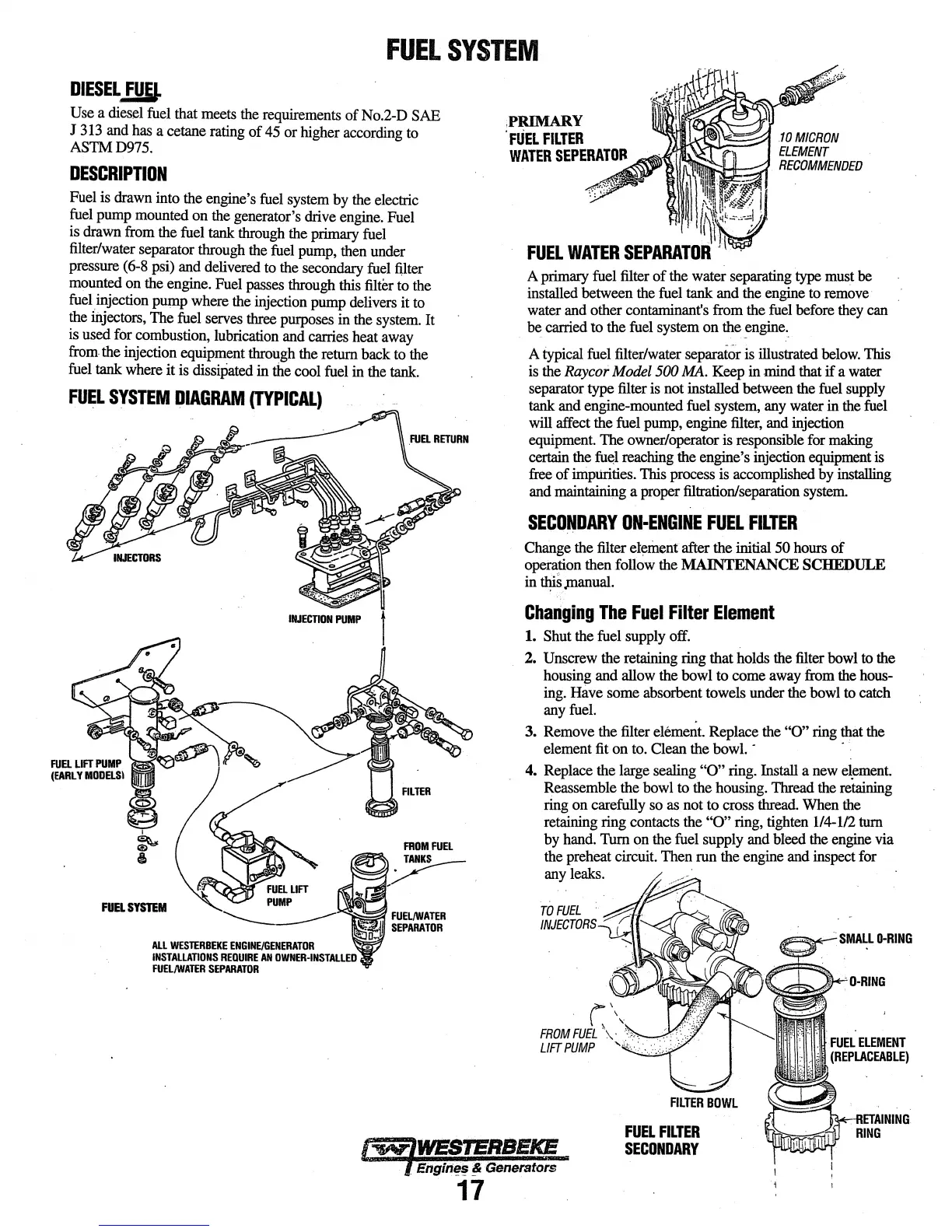

;PRIMARY

.

FUEL

FILTER

WATER

SEPERATOP

tO

MICRON

ELEMENT

:-L.II--~J

RECOMMENDED

A primary fuel filter

of

the water separating type must be

installed between the fuel tank and

the engine

to

remove·

water and other contaminant's from the

fuel

before

they

can

be carried to the

fuel

system on the

~ngine~_

A typical fuel filter/water separator

is

illustrated

below.

This

is

the Raycor Model500 MA.

Keep

in mind that

if

a water

separator

type filter

is

not installed between the

fuel

supply

tank and engine-mounted fuel system, any water in the

fuel

will affect the fuel pump, engine

filter,

and injection

equipment The owner/operator

is responsible for

making

certain the

~1

reaching the engine's injection equipment is

free

of iniplirities.

This

process is accomplished by installing

and maintaining a proper filtration/separation

system.

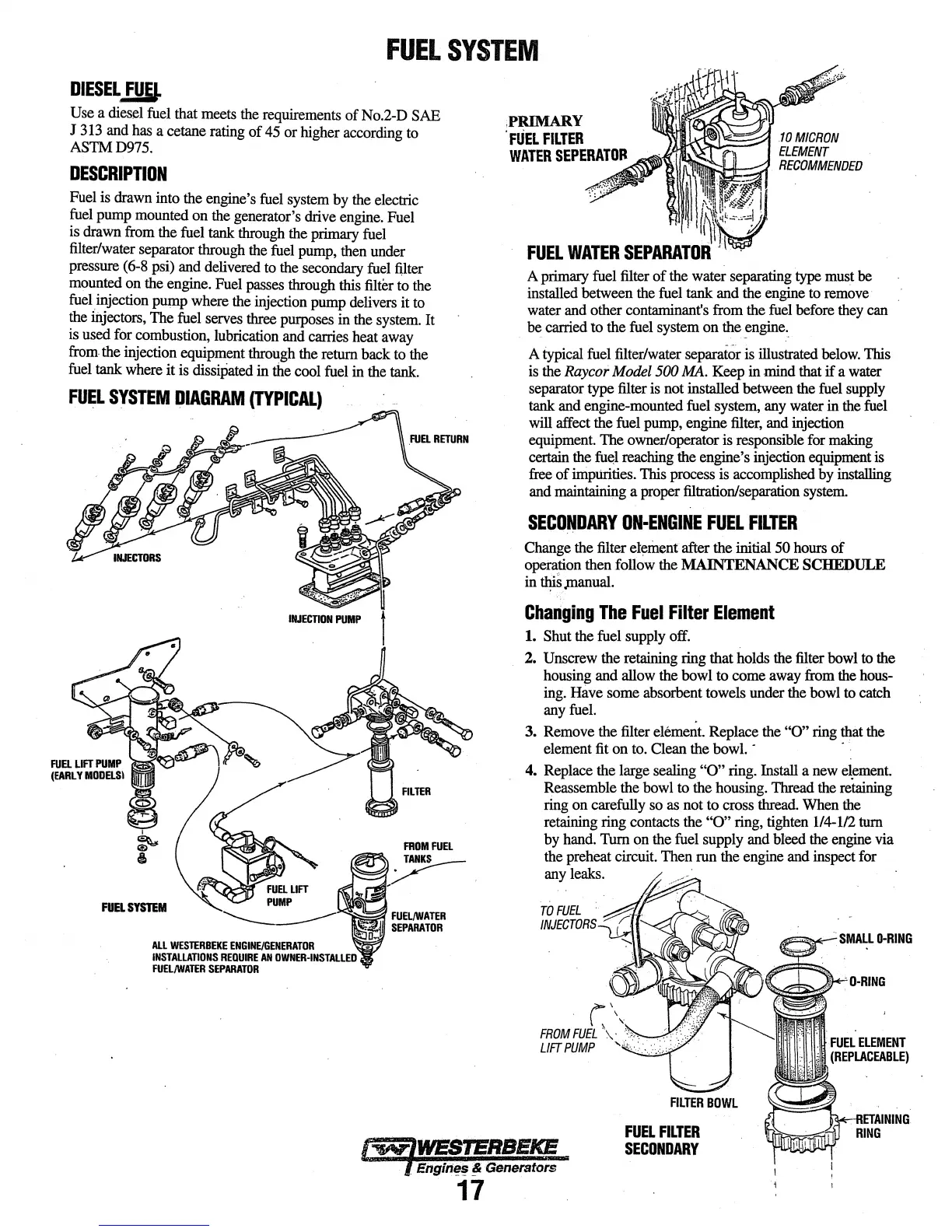

SECONDARY

ON-ENGINE

FUEL

FILTER

Change the filter element

after

the initial 50 hours

of

operation then follow the MAINTENANCE

SCHEDULE

in

~s.manual.

Changing

The

Fuel

Filter

Element

1. Shut the fuel supply

off.

2.

Unscrew the retaining ring that holds the filter

bowl

to

the

housing and allow the bowl to come away from the

hous-

ing. Hive some absorbent towels under the bowl to catch

any

fuel.

3. Remove the filter element. Replace the

"0"

ring that the

element

fit

on

to.

Clean the bowl. - · ·

4. Replace the large sealing

"0"

ring. Install a new

e~ement

Reassemble the bowl

to

the housing. Thread the retaining

ring on carefully

so

as

not to cross thread. When the

retaining ring contacts the

"0"

ring, tighten 1/4-1/2 turn

by hand. Turn

on

the fuel supply

and

bleed the engine via

the preheat circuit Then run the engine and inspect for

anyleaks.

·

{~IWESTERBEKE

l

Engi~~

!ft

Generators

FUEL

FILTER

SECONDARY

.

17

Loading...

Loading...