S.21

SA1

AND

SAO

MANUAL

CLUTCH

ADJUSTMENTS

With the transmission secured to the

engine,

replace

all water lines,

etc.

However, do

not

connect

the shifting linkage until all the

adjustments have

been

made and

are

satis-

factorily

tested~

Before securing the propeller

half

coupling to

the

gear

half

coupling, check to make

certain

that

the couplings do not run

out

more than

.002

inches

wi

th respect to

each

other.

Study

section IIAlignment to Engine

II

on Pages

14 and 15

of

Technical Manual.

The

transmission should

be

filled

with new oil

as

specified under lubrication.

The

transmission

can

be

parti ally adjusted

be-

fore the engine has

been

run. However, a

complete running test

is

necessary to

satisfact-

orily determine whether the adjustments have

been

properly made.

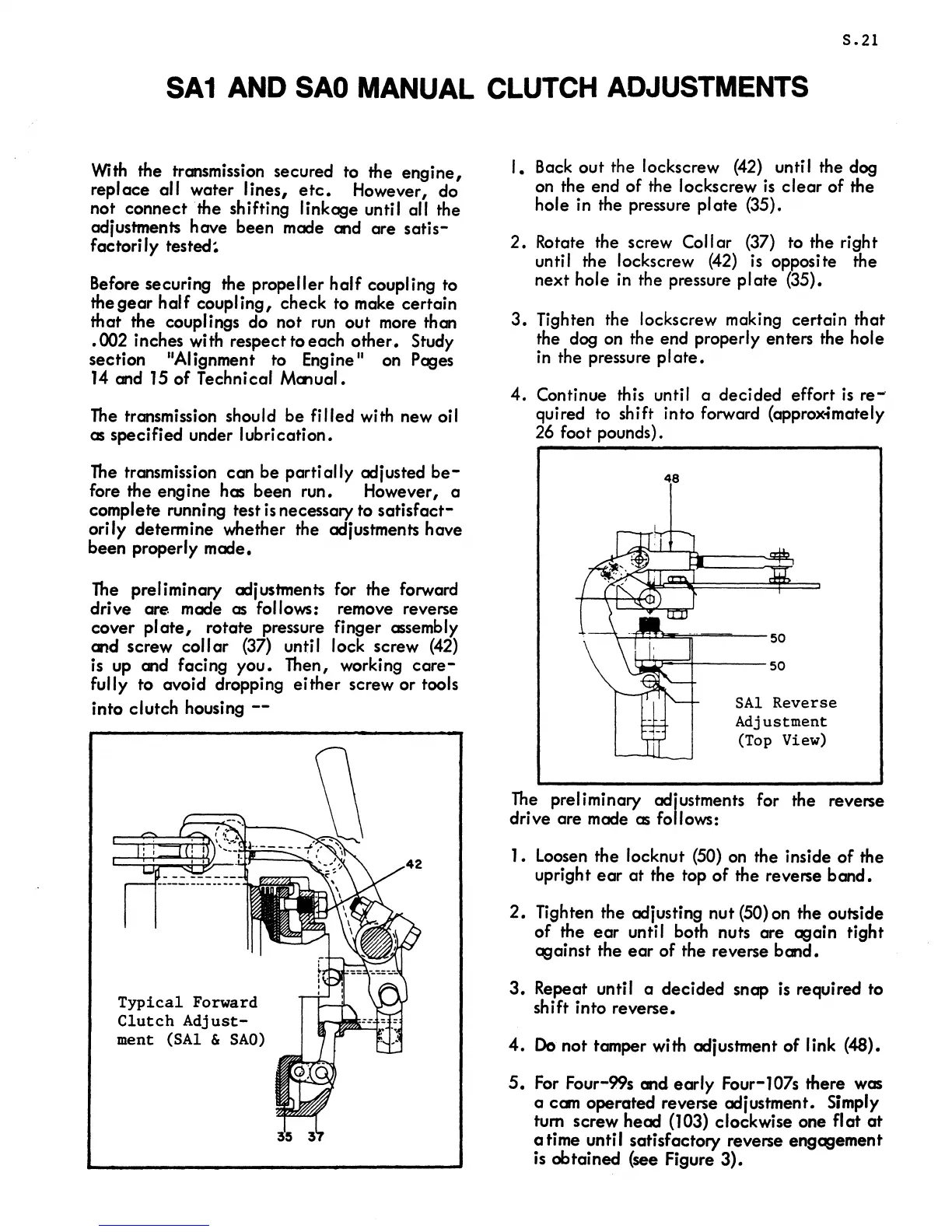

The

preliminary adjustments for the forward

drive

are.

made as follows: remove reverse

cover

plate,

rotate

pressure finger assembly

CI1d

screw

collar

(37) until lock screw

(42)

is up and facing

you.

Then, working

care-

fully to avoid dropping

either

screw or tools

into

clutch housing

--

Typical

Forward

Clutch

Adjust-

ment (SAl &

SAO)

I.

Back

out

the lockscrew

(42)

until the dog

on the end

of

the lockscrew

is

clear

of

the

hole in the pressure

plate

(35).

2.

Rotate the screw Collar (37) to the right

until the lockscrew

(42)

is

oPEosite the

next hole

in

the pressure

plate

(35).

3.

Tighten the lockscrew making certain

that

the dog on the end properly enters the hole

in

the pressure

plate.

4.

Continue this until a

decided

effort

is

re-

quired to shift into forward (approximately

26 foot pounds).

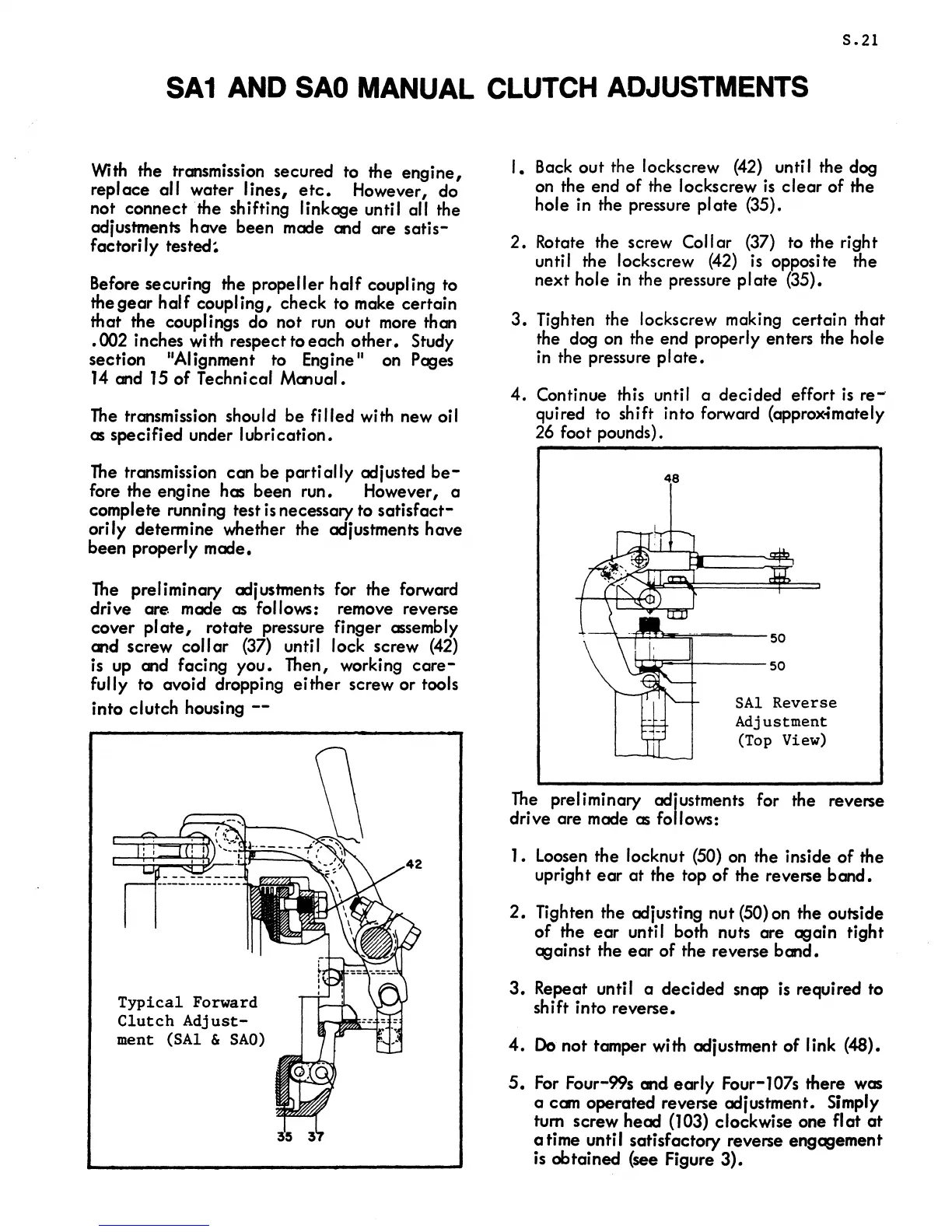

48

--~~O-~~----50

~n==4----

50

SAl

Reverse

Adjustment

(Top View)

The

preliminary adjustments for the reverse

drive are made

as

follows:

1.

Loosen the locknut (50) on the inside

of

the

upright

ear

at

the top

of

the reverse

band.

2.

TIghten the adjusting nut (50) on the outside

of

the

ear

unti I both nuts are again tight

against the

ear

of

the reverse

band.

3.

Repeat until a

decided

snap is required to

shift into reverse.

4.

Do

not

tamper with adjustment

of

link (48).

5.

For

Four-99s

and

early

Four-l07s there was

a cam operated reverse adjustment. Simply

tum screw

head

(103) clockwise one

flat

at

a time until satisfactory reverse engagement

is

obtained (see Figure

3).

Loading...

Loading...