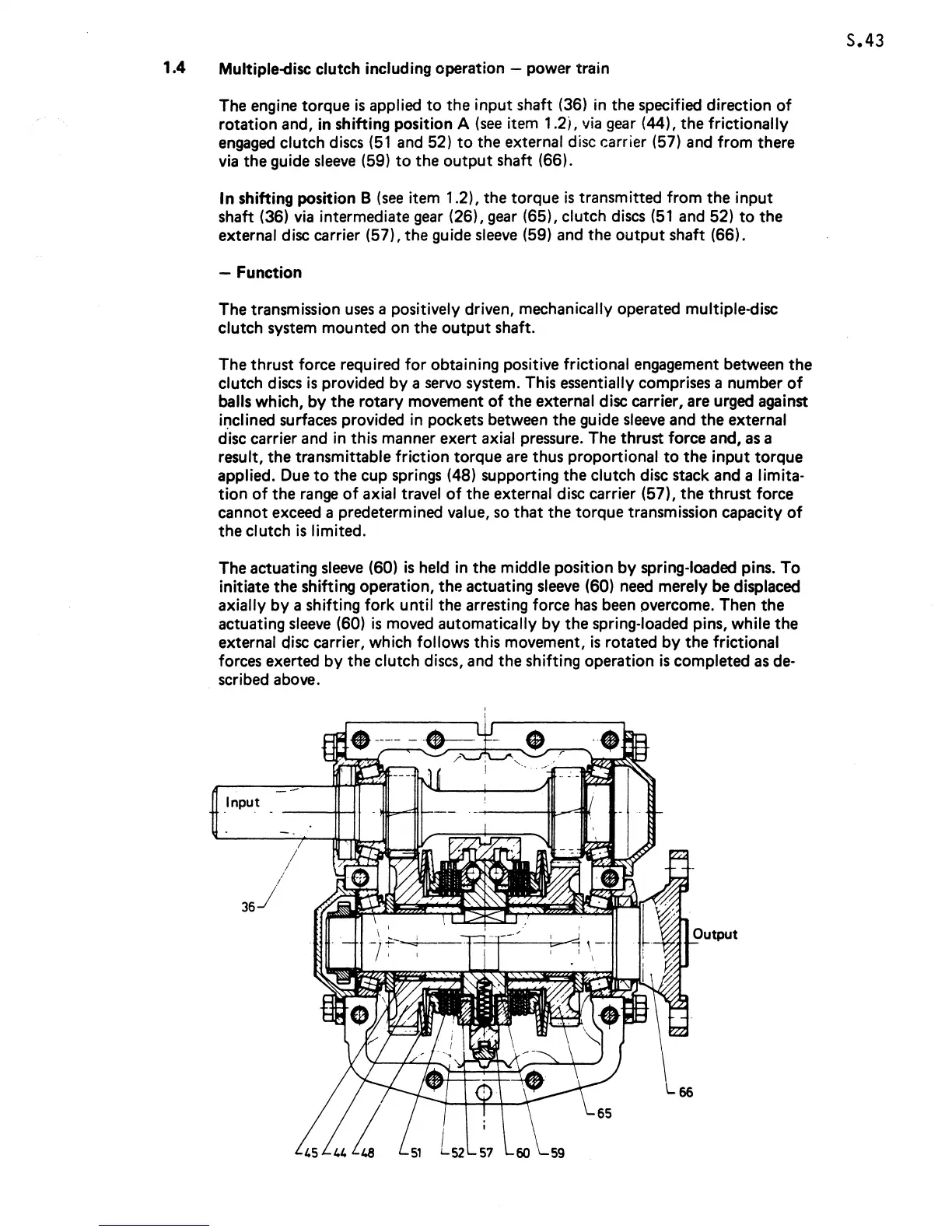

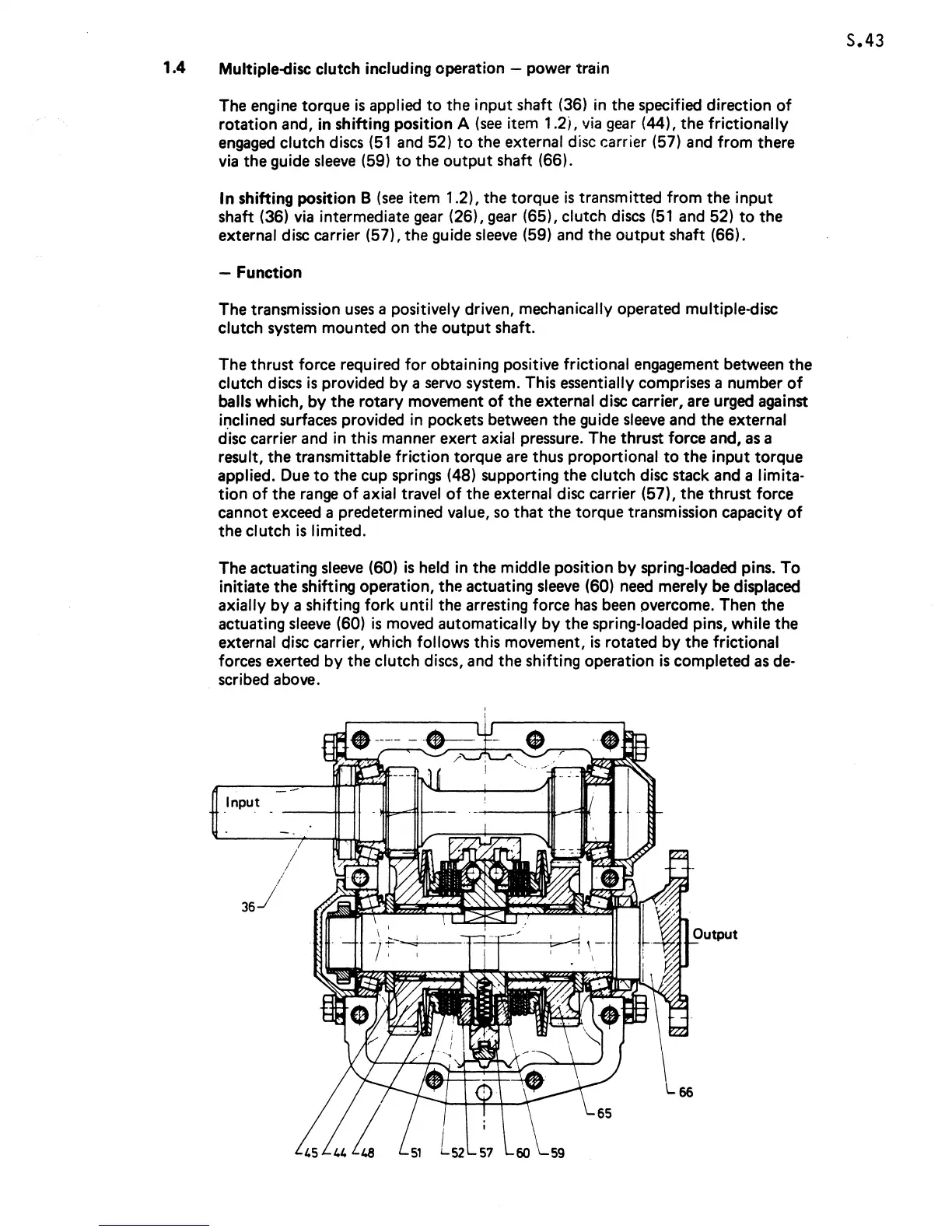

1.4 Multiple-disc clutch including operation - power train

The engine torque

is

applied

to

the input shaft (36) in the specified direction

of

rotation and, in shifting position A

(see

item 1.2i,

via

gear

(44), the frictionally

engaged

clutch

discs

(51

and

52)

to

the external disc carrier (57) and from there

via

the guide

sleeve

(59)

to

the output shaft (66).

In

shifting position B

(see

item 1.2), the torque

is

transmitted from the input

shaft (36)

via

intermediate

gear

(26),

gear

(65), clutch

discs

(51

and

52)

to

the

external disc carrier (57), the guide

sleeve

(59)

and

the output shaft (66).

- Function

The transmission

uses

a positively driven, mechanically operated multiple-disc

clutch

system

mounted on the output shaft.

The thrust force required

for

obtaining positive frictional engagement between the

clutch

discs

is

provided

by

a

servo

system. This essentially comprises a number

of

balls which, by the rotary movement

of

the external disc carrier,

are

urged against

inclined

surfaces

provided

in

pockets between the guide

sleeve

and the external

d'isc

carrier and in this manner exert axial

pressure.

The thrust force and,

as

a

result, the transmittable

friction

torque

are

thus proportional

to

the input torque

applied.

Due

to

the cup springs (48) supporting the clutch disc stack and a limita-

tion

of

the

range

of

axial travel

of

the external disc carrier (57), the thrust force

cannot

exceed

a predetermined value,

so

that the torque transmission capacity

of

the clutch

is

limited.

The actuating

sleeve

(60)

is

held in the middle position

by

spring-loaded pins.

To

initiate the shifting operation, the actuating

sleeve

(60)

need

merely

be

displaced

axially

by

a shifting

fork

until

the arresting force

has

been

overcome. Then the

actuating

sleeve

(60)

is

moved automatically

by

the spring-loaded pins, while the

external disc carrier, which follows this movement,

is

rotated

by

the frictional

forces exerted

by

the clutch discs,

and

the shifting operation

is

completed

as

de-

scribed above.

Input

36

Output

S.43

Loading...

Loading...