THE ENGINE

A

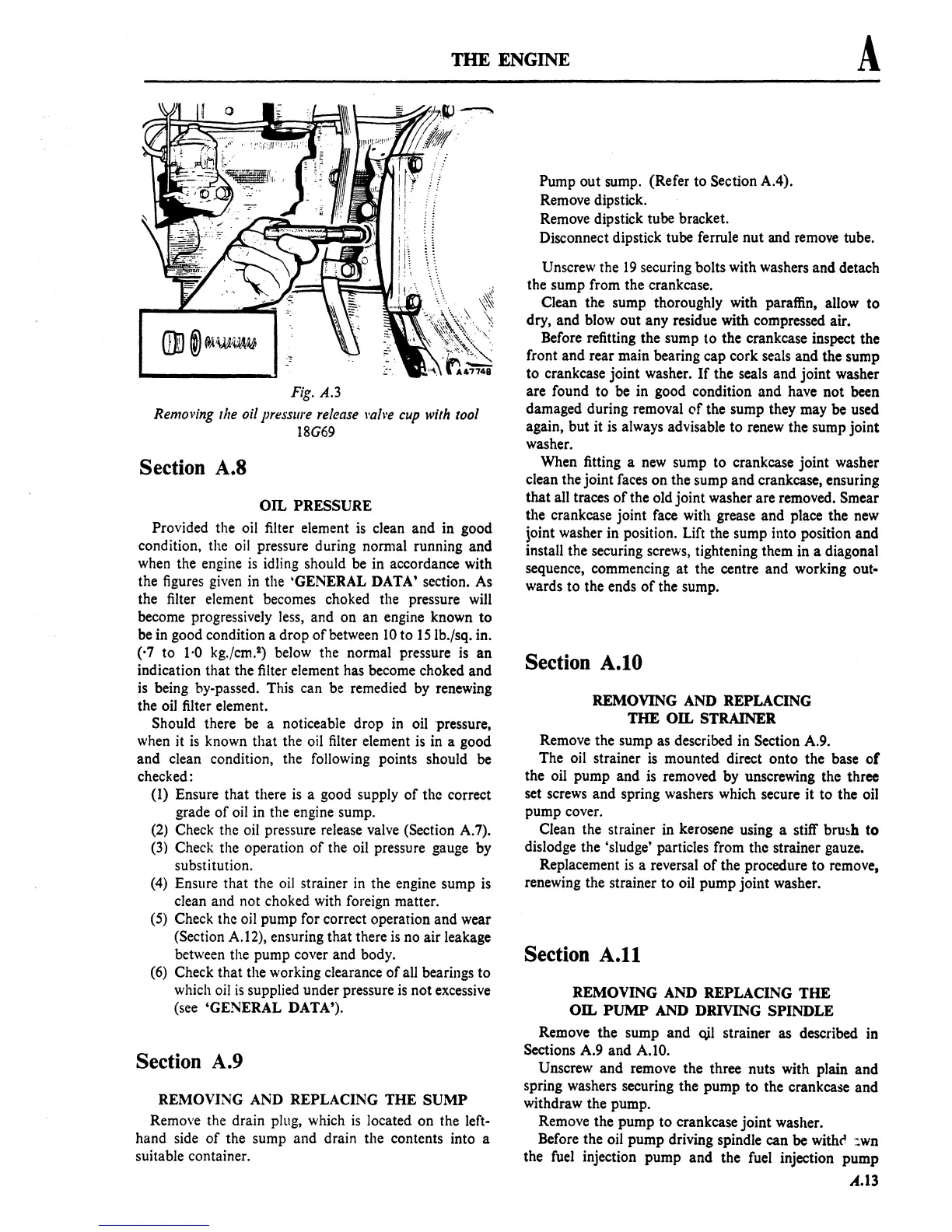

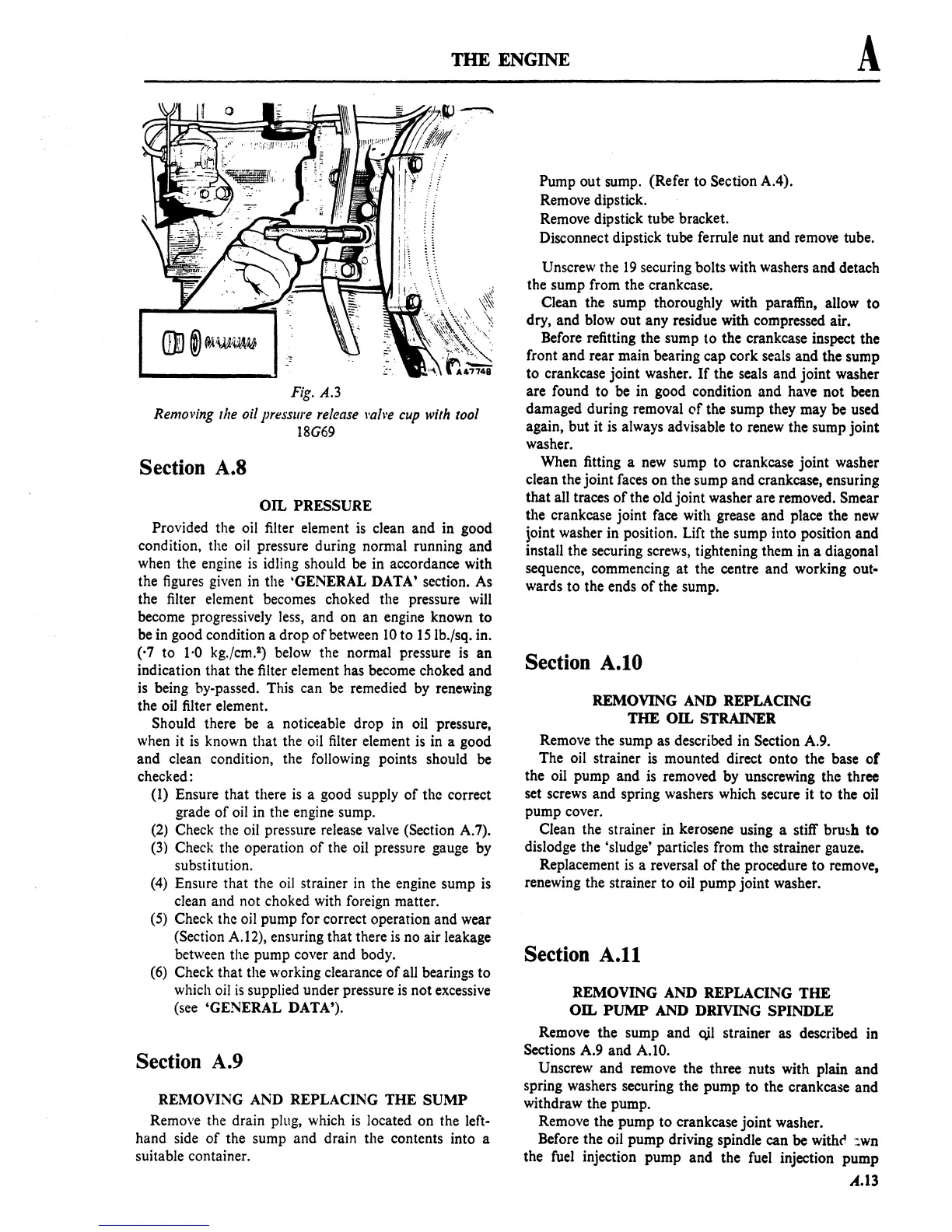

Fig.

A.3

Removing

lire

oil pressure

release

I'ail'e

cup

with

tool

18G69

Section

A.8

OIL

PRESSURE

Provided the oil filter element

is

clean and in good

condition. the

oil

pressure during normal running and

when the engine

is

idling should be in accordance with

the figures given

in

the 'GENERAL DATA' section. As

the filter element becomes choked the pressure will

become progressively less, and on an engine known to

be in good condition a drop

of

between

10

to 15Ib./sq. in.

(,7 to

1·0 kg,fcm.') below the normal pressure

is

an

indication that the filter element has become choked and

is

being by-passed. This can be remedied by renewing

the oil filter element.

Should there be a noticeable drop in oil pressure,

when it

is

known that the oil filter element

is

in a good

and clean condition. the following points should

be

checked:

(I) Ensure that there

is

a good supply

of

the correct

grade

of

oil in the engine sump.

(2)

Check the oil pressure release valve (Section A.7).

(3)

Check the operation

of

the oil pressure gauge by

substitution.

(4)

Ensure that the

oil

strainer in the engine sump

is

clean and not choked with foreign matter.

(5)

Check the oil pump for correct operation and wear

(Section A.12), ensuring that there

is

no air leakage

between the pump cover and body.

(6)

Check that the working clearance

of

aU

bearings to

which oil

is

supplied under pressure

is

not excessive

(see 'GENERAL DATA').

Section

A.9

REMOVING AND REPLACING

THE

SUMP

Remove the drain plug, which

is

located on the left-

hand side

of

the sump and drain the contents into a

suitable container.

Pump out sump. (Refer to Section A.4).

Remove dipstick.

Remove dipstick tube bracket.

Disconnect dipstick tube ferrule nut and remove tube.

Unscrew the

19

securing bolts with washers and detach

the sump from the crankcase.

Clean the sump thoroughly with paraffin, allow to

dry, and

blowout

any residue with compressed air.

Before refitting the sump to the crankcase inspect the

front and rear main bearing cap cork seals and the sump

to crankcase joint washer.

If

the seals and joint washer

are found to be in good condition and have not been

damaged during removal

of

the sump they may be used

again, but it

is

always advisable to renew the sump joint

washer.

When fitting a

new

sump to crankcase joint washer

clean the joint faces on the sump and crankcase, ensuring

that all traces

of

the old joint washer are removed. Smear

the crankcase joint face with grease and place the new

joint washer in position.

Lift

the sump into position and

install the securing screws, tightening them in a diagonal

sequence, commencing

at

the centre and working out-

wards to the ends

of

the sump.

Section

A.IO

REMOVING AND REPLACING

THE

OIL

STRAINER

Remove the sump as described in

Section A.9.

The oil strainer

is

mounted direct onto the base

of

the oil pump and

is

removed by unscrewing the three

set screws and spring washers which secure it to the oil

pump cover.

Clean the strainer in kerosene using a stiff

bru~h

to

dislodge the 'sludge' particles from the strainer gauze.

Replacement

is

a reversal

of

the procedure to remove,

renewing the strainer to oil pump joint washer.

Section

A.II

REMOVING AND REPLACING

THE

OIL

PUMP

AND DRIVING SPINDLE

Remove the sump and

oJl

strainer as described in

Sections A.9 and

A.tO.

Unscrew and remove the three nuts with plain and

spring washers securing the pump to the crankcase and

withdraw the pump.

Remove the pump to crankcase joint washer.

Before the oil pump driving spindle can be

withe'

:wn

the fuel injection pump and the fuel injection pump

A.13

Loading...

Loading...