A

THE ENGINE

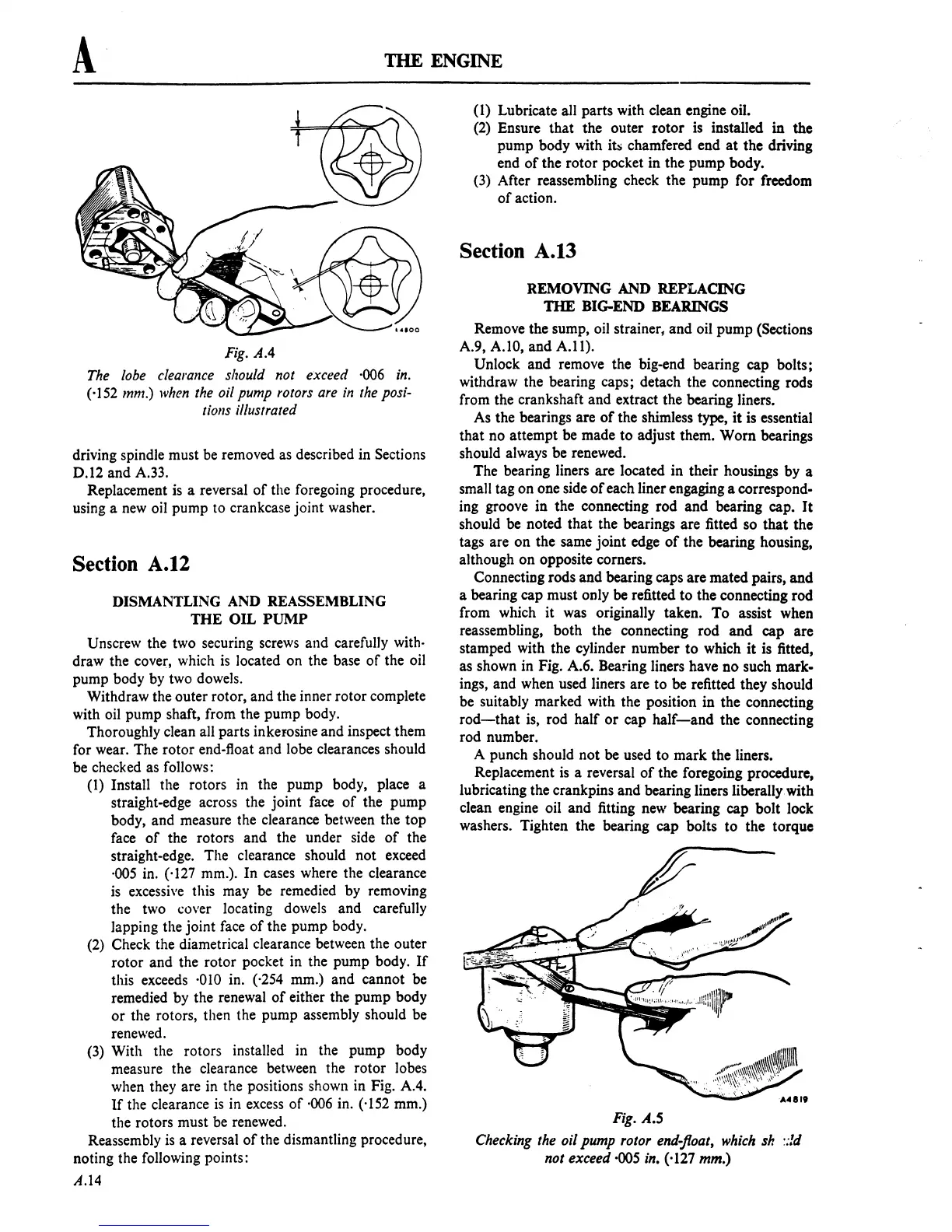

Fig.

A.4

The lobe

clea/'a1lce

should not exceed

·006

in.

(·152 mm.)

when

the oil pump rotors are

in

the posi-

tions

illustrated

driving spindle must be removed as described in Sections

D.l2

and A.33.

Replacement is a reversal

of

the foregoing procedure,

using a new oil pump to crankcase joint washer.

Section

A.12

DISMANTLING AND REASSEMBLING

THE

OIL

PUMP

Unscrew the two securing screws and carefully with·

draw the cover, which

is

located on the base

of

the oil

pump body by two dowels.

Withdraw the outer rotor, and the inner rotor complete

with oil pump shaft, from the pump body.

Thoroughly clean all parts inkeFosine and inspect them

for wear. The rotor end-float and lobe clearances should

be checked as follows:

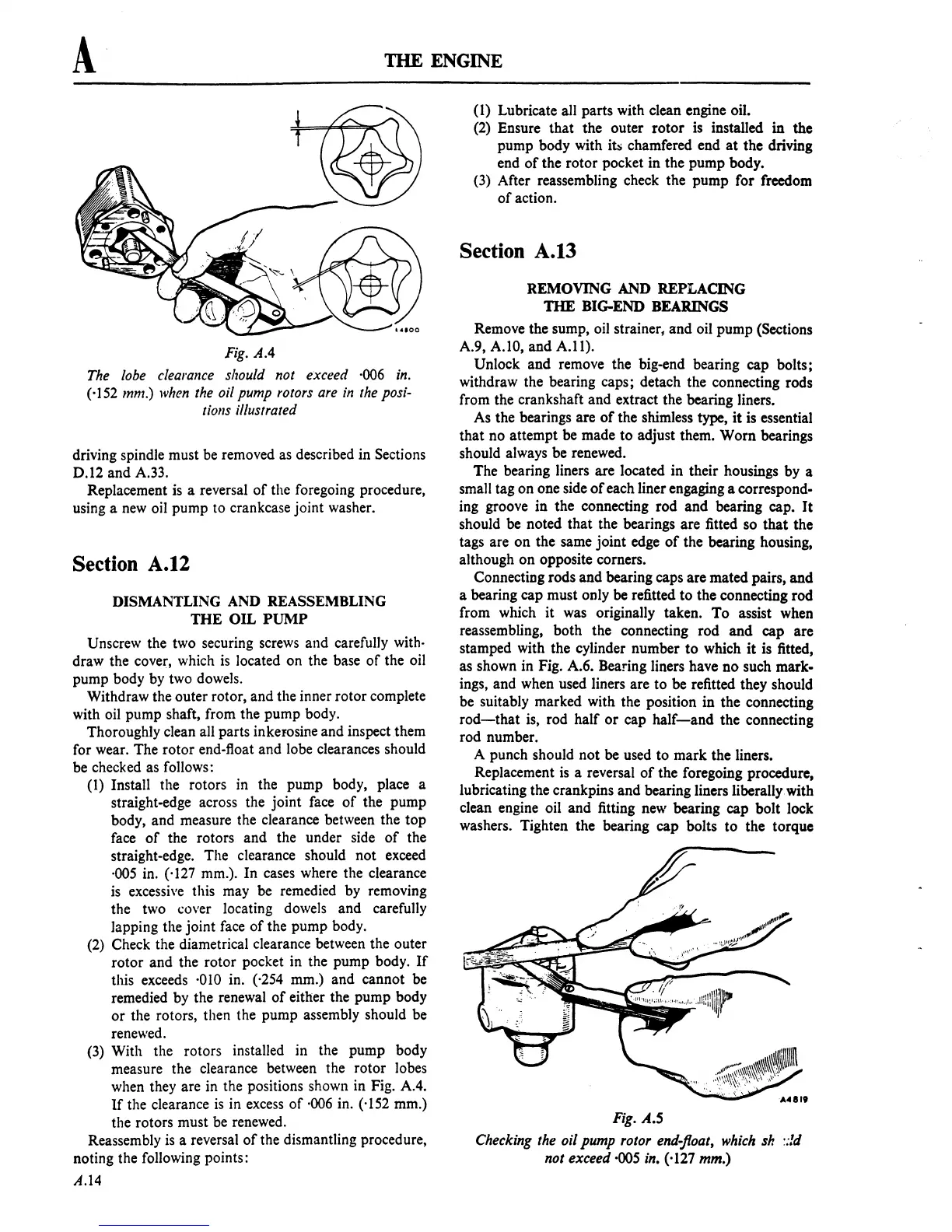

(1)

Install the rotors in the pump body, place a

straight-edge across the joint face

of

the pump

body, and measure the clearance between the

top

face

of

the rotors and the under side

of

the

straight-edge. The clearance should

not

exceed

·005

in. (·127 mm.).

In

cases where the clearance

is

excessive this may be remedied by removing

the two cover locating dowels and carefully

lapping the joint face

of

the pump body.

(2)

Check the diametrical clearance between the outer

rotor and the rotor pocket in the pump body.

If

this exceeds

·010

in. (·254 mm.) and cannot be

remedied by the renewal

of

either the pump body

or

the rotors, then the pump assembly should be

renewed.

(3) With the rotors installed in the pump body

measure the clearance between the rotor lobes

when they are in the positions shown in Fig. A.4.

If

the clearance

is

in excess

of

·006

in. (·152 mm.)

the rotors must be renewed.

Reassembly

is

a reversal

of

the dismantling procedure,

noting the following points:

A.l4

(1) Lubricate all parts with clean engine oil.

(2)

Ensure that the outer

rotor

is installed in the

pump body with

its chamfered end

at

the driving

end

of

the rotor pocket in the pump body.

(3)

After reassembling check the pump for freedom

of

action.

Section A.13

REMOVING AND REPLACING

THE

BIG-END BEARINGS

Remove the sump, oil strainer, and oil pump (Sections

A.9, A.lO, and

A.Il).

Unlock and remove the big-end bearing cap bolts;

withdraw the bearing caps; detach the connecting rods

from the crankshaft and extract the bearing liners.

As the bearings are

of

the shimless type,

it

is essential

that

no attempt be made

to

adjust them. Worn bearings

should always be renewed.

The bearing liners are located in their housings by a

small tag

on

one side

of

each liner engaging a correspond-

ing groove in the connecting rod

and

bearing cap.

It

should be noted

that

the bearings are fitted so

that

the

tags are on the same joint edge

of

the bearing housing,

although

on

opposite corners.

Connecting rods and bearing caps are mated pairs, and

a bearing cap must only be refitted

to

the connecting rod

from which

it

was originally taken.

To

assist when

reassembling, both the connecting rod

and

cap are

stamped with the cylinder number

to

which

it

is fitted,

as shown in Fig. A.6. Bearing liners have

no

such mark-

ings, and when used liners are

to

be refitted they should

be suitably marked with the position in the connecting

rod-that

is, rod

half

or

cap

half-and

the connecting

rod number.

A punch should not be used

to

mark

the liners.

Replacement is a reversal

of

the foregoing procedure.

lubricating the crankpins and bearing liners liberally with

clean engine oil and fitting new bearing cap bolt lock

washers. Tighten the bearing cap bolts

to

the torque

Fig.

A.5

Checking the oil pump rotor

end-JIoat,

which

sir

::!d

not exceed ·005 in. (·127 mm.)

Loading...

Loading...