A

THE ENGINE

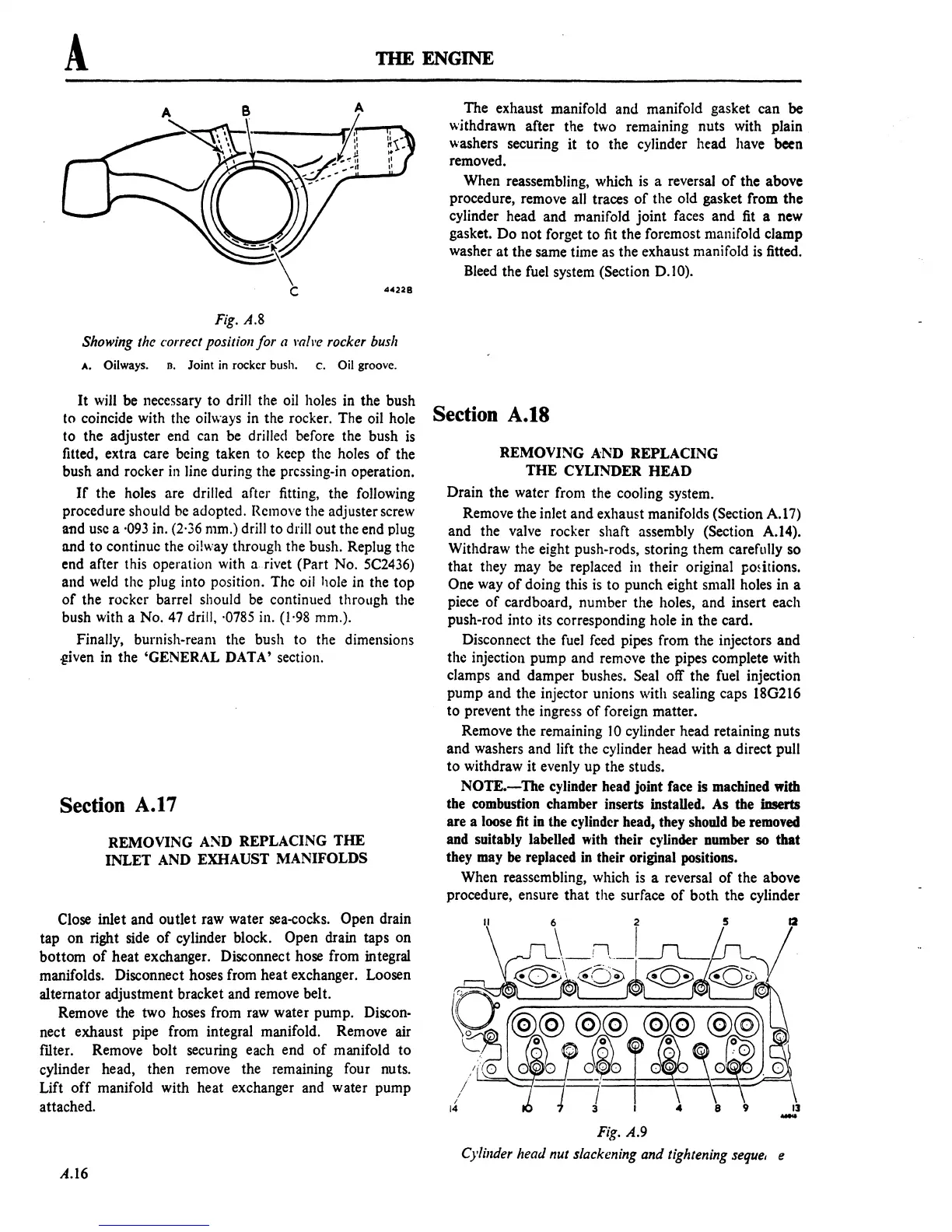

Fig.

A.8

Showing

the correct position for a mh'e rocker bush

A. Oilways.

n.

Joint

in

rockcr bush. c.

Oil

groovc.

It

will be necessary to drill the oil holes in the bush

to coincide with the oilways in the rocker. The oil hole

to the adjuster end can be drilled before the bush

is

fitted, extra care being taken to keep the holes

of

the

bush

and

rocker in line during the pressing-in operation.

If

the holes are drilled after fitting, the following

procedure should be adopted. Remove the adjuster screw

and use a ·093 in. (2'36 mm.) drill to drill out the end plug

and

to

continue the oi!\\'ay through the bush. Replug the

end after this operation with a rivet (Part No. 5C2436)

and weld the plug into position. The oil hole in the

top

of

the rocker barrel should be continul!d through the

bush with a No.

47 drill, ·0785 in. (1·98 mm.).

Finally, burnish-ream the bush to the dimensions

.given in the 'GENERAL DATA' section.

Section A.I7

REMOVING AND REPLACING

THE

INLET

AND EXHAUST MANIFOLDS

Close inlet and outlet raw water sea-cocks. Open drain

tap

on

right side

of

cylinder block. Open drain taps on

bottom

of

heat

exchanger. Disconnect hose from integral

manifolds. Disconnect hoses from heat exchanger. Loosen

alternator adjustment bracket and remove belt.

Remove the two hoses from raw water pump.

Discon-

nect exhaust pipe from integral manifold. Remove air

filter. Remove bolt securing each end

of

manifold

to

cylinder head, then remove the remaining four nuts.

Lift

off

manifold with heat exchanger and water pump

attached.

A.l6

The exhaust manifold and manifold gasket can

be

withdrawn after the two remaining nuts with plain

washers securing it

to

the cylinder head have been

removed.

When reassembling, which

is

a reversal

of

the above

procedure, remove all traces

of

the old gasket from the

cylinder head

and

manifold

joint

faces and fit a new

gasket.

Do

not forget to fit the foremost manifold clamp

washer

at

the same time as the exhaust manifold

is

fitted.

Bleed the fuel system

(Section 0.10).

Section A.IS

REMOVING AND REPLACING

THE

CYLINDER HEAD

Drain the water from the cooling system.

Remove the inlet and exhaust manifolds

(Section A.17)

and the valve rocker shaft assembly (Section A.14).

Withdraw the eight push-rods, storing them carefully so

that

they may be replaced in their original pmitions.

One

way

of

doing this

is

to punch eight small holes in a

piece

of

cardboard, number the holes, and insert each

push-rod into its corresponding hole in the card.

Disconnect the

fuel

feed pipes from the injectors and

the injection pump and remove the pipes complete with

clamps and damper bushes.

Seal off the fuel injection

pump and the injector unions with sealing caps 180216

to prevent the ingress

of

foreign matter.

Remove the remaining

10

cylinder head retaining nuts

and washers and lift the cylinder head with a direct pull

to

withdraw it evenly up the studs.

NOTE.-The

cylinder head joint face is machined with

the combustion chamber inserts installed. As the inserts

are a loose fit

in

the cylinder head, they should

be

removed

and suitably labelled with their cylinder number so that

they may

be

replaced

in

their original positions.

When reassembling, which

is

a reversal

of

the above

procedure, ensure

that

the surface

of

both the cylinder

12

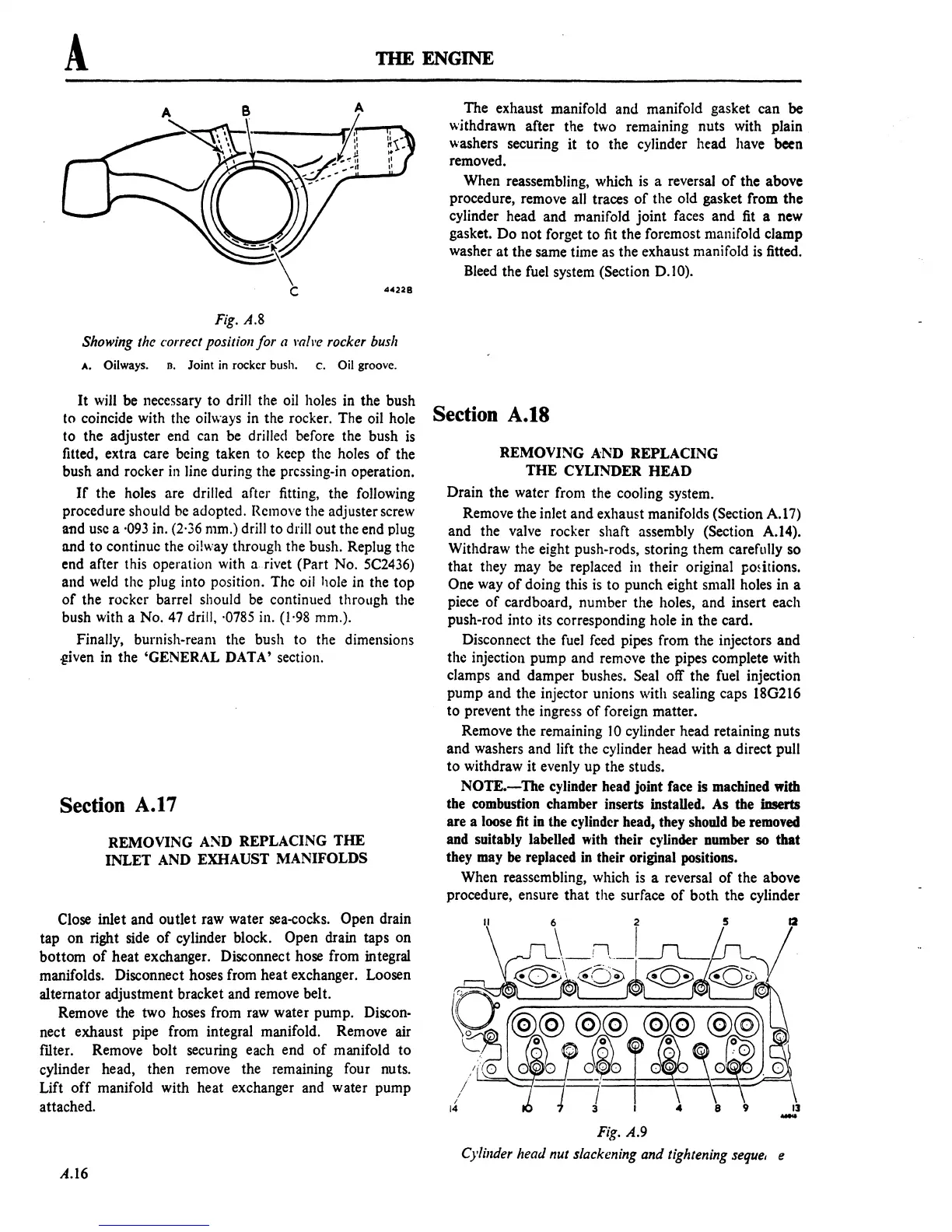

Fig. A.9

Cylillder head nut slackening and tightening seque, e

Loading...

Loading...