A

THE ENGINE

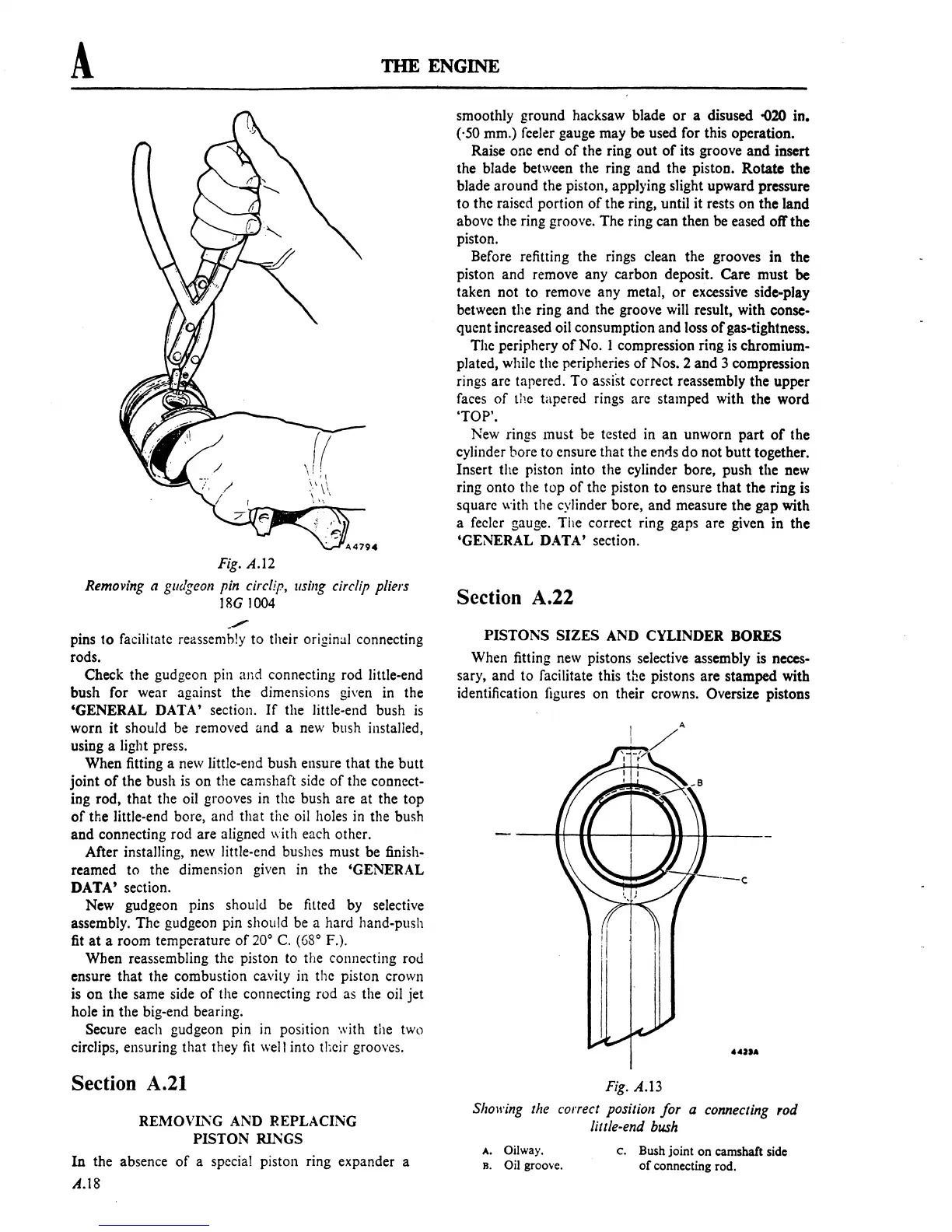

Fig.

A.I2

Removing a gudgeon pin eire/ip,

!Ising

eirclip pliers

18G

1004

_./

pins

to

facilitate reassemhly

to

their original connecting

rods.

Check the gudgeon pin and connecting rod little-end

bush for wear against the dimensions given in the

'GENERAL

DATA'

section.

If

the little-end bush

is

worn it should be removed

and

a new bllSh instalied,

using a light press.

When fitting a new little-end bush ensure that the

butt

joint

of

the bush

is

on

the camshaft side

of

the connect-

ing rod,

that

the oil grooves in the bush are at the

top

of

the little-end bore, and

that

the oil holes in the bush

and

connecting rod are aligned with each other.

After installing, new little-end bushes must be

finish-

reamed

to

the dimemion given in the

'GENERAL

DATA'

section.

New gudgeon pins should be

fItted by selective

assembly. The gudgeon pin should be a hard

hand-push

fit

at

a room temperature

of

20°

C.

(68

0

F.).

When reassembling the piston to the connecting rod

ensure

that

the combustion cavity in the piston erown

is

on

the same side

of

the connecting rod as the oil jet

hole in the big-end bearing.

Secure each gudgeon pin in position with the two

circlips, ensuring that they

fit

well into their grooves.

Section

A.21

REMOVL,\G AND REPLACING

PISTON

RINGS

In

the absence

of

a special piston ring expander a

A.18

smoothly ground hacksaw blade

or

a disused

-020

in.

('50 mm.) feeler gauge may be used for this operation.

Raise one end

of

the ring

out

of

its groove

and

insert

the blade between the ring

and

the piston.

Rotate

the

blade around the piston, applying slight upward pressure

to

the raised portion

of

the ring, until it rests

on

the

land

above the ring groove. The ring can then be eased off the

piston.

Before refitting the rings clean the grooves in the

piston and remove any carbon deposit. Care

must

be

taken not

to

remove any metal,

or

excessive side-play

between the ring and the groove will result, with

conse-

quent increased oil consumption and loss

of

gas-tightness.

The periphery

of

No.1

compression ring is chromium-

plated, while the peripheries

of

Nos. 2

and

3 compression

rings arc tapered.

To

assist correct reassembly the upper

faces

of

the tapered rings are stamped with the word

'TOP'.

New rings must be tested in

an

unworn

part

of

the

cylinder bore to ensure that the

entis

do

not

butt

together.

Insert the piston into the cylinder bore, push the new

ring

onto

the top

of

the piston

to

ensure

that

the ring is

square

with the cylinder bore, and measure the gap with

a feeler gauge. The correct ring gaps are given in the

'GENERAL DATA' section.

Section A.22

PISTONS

SIZES

AND CYLINDER

BORES

When fitting new pistons selective assembly is neces-

sary, and

to

facilitate this the pistons

are

stamped with

identification

figures

on

their crowns. Oversize pistons

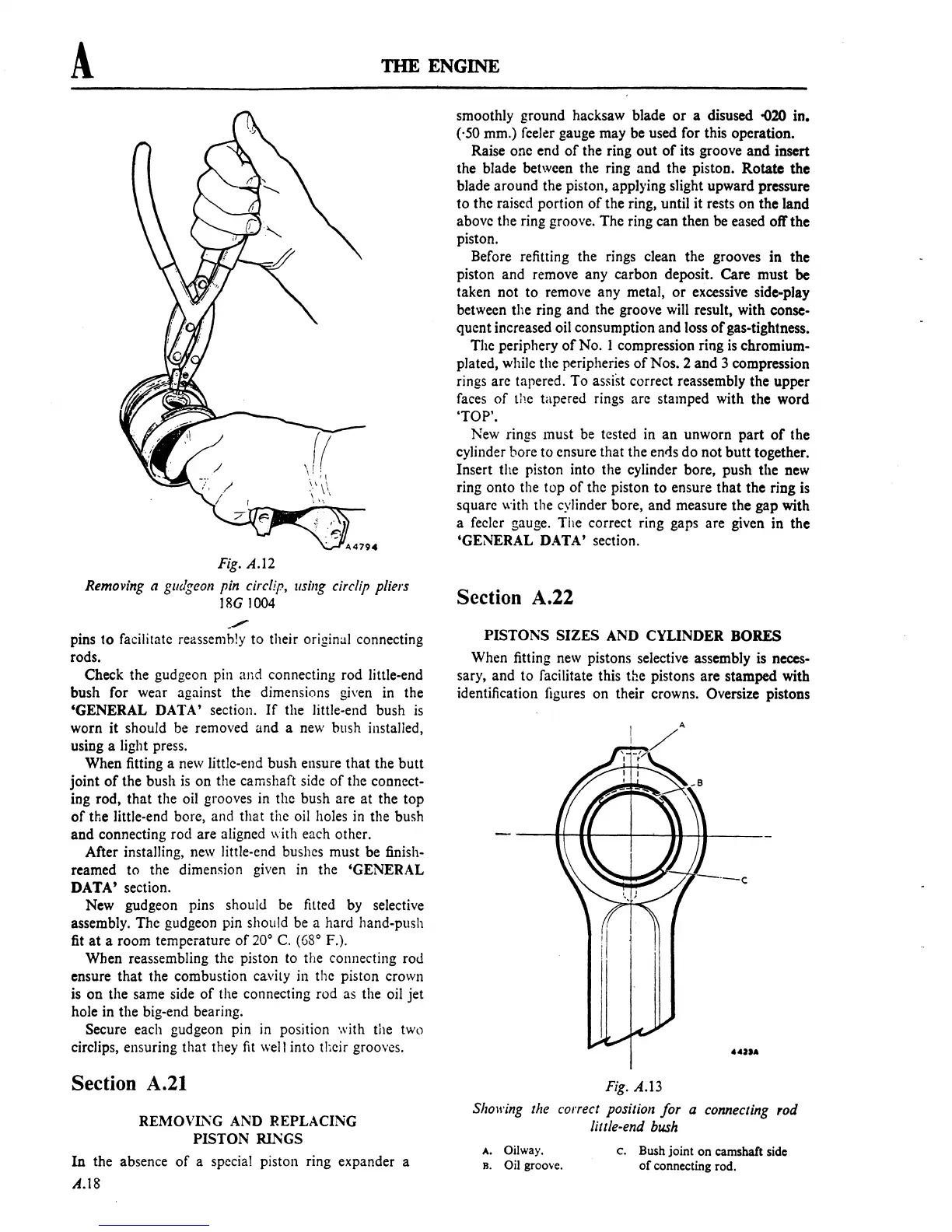

Fig. A.13

Sho1l'ing

the correct position

for

a connecting rod

little-end

bush

A. Oilway.

B. Oil groove.

c. Bush joint on camshaft side

of

connecting rod.

Loading...

Loading...