TIlE

ENGINE

A

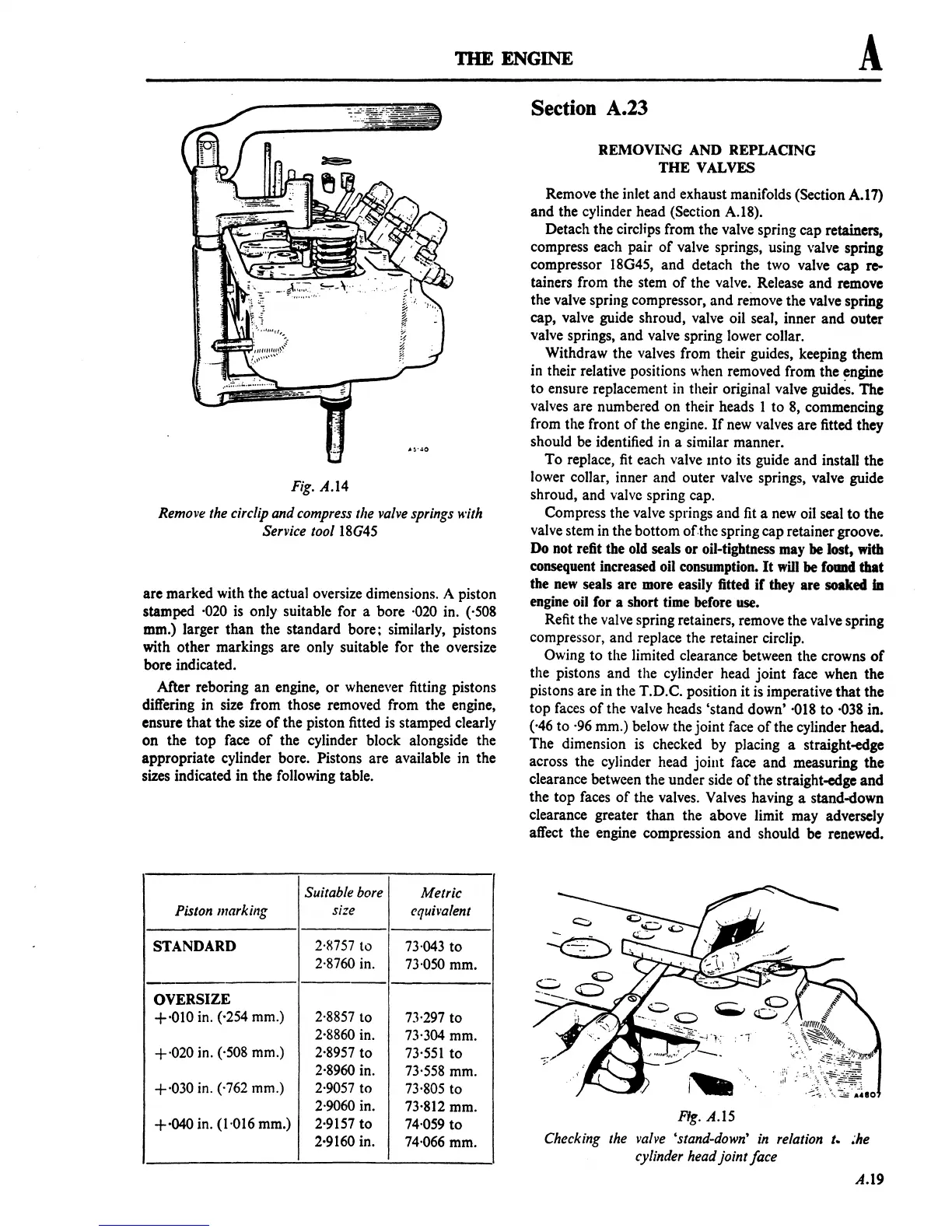

Fig. A.14

Remove the eire/ip and compress

the valve springs with

Service

tool 18G45

are marked with the actual oversize dimensions. A piston

stamped

·020

is only suitable for a bore

·020

in.

(·508

mm.) larger

than

the standard bore; similarly, pistons

with other markings are only suitable for the oversize

bore indicated.

After reboring

an

engine,

or

whenever fitting pistons

differing in size from those removed from the engine,

ensure that the size

of

the piston fitted

is

stamped clearly

on

the top face

of

the cylinder block alongside the

appropriate cylinder bore. Pistons are available in the

sizes indicated in the following table.

Suitable bore

Metric

Piston marking

size

equh'alent

STANDARD

2·R757

to

73·043

to

2·8760

in.

73·050

mm.

OVERSIZE

+'010

in.

(·254

mm.)

2·8857

to

7'3'297

to

2·8860

in.

73·304

mm.

+020

in. ('508 mm.)

2-8957

to

73·551

to

2·8960

in.

73'558

mm.

+·030 in. ('762 mm.)

2·9057

to

73-805

to

2·9060

in.

73·812

mm.

+·040 in. (1'016 mm.)

2·9157

to

74·059

to

2·9160

in.

74·066

mm.

Section

A.23

REMOVING AND REPLACING

THE

VALVES

Remove the inlet and exhaust manifolds (Section

A.17)

and

the cylinder head (Section A.l8).

Detach the circJips from the valve spring cap retainers,

compress each pair

of

valve springs, using valve spring

compressor

18G45,

and

detach the two valve cap

re-

tainers from the stem

of

the valve. Release and remove

the valve spring compressor, and remove the valve spring

cap, valve guide shroud, valve oil seal, inner

and

outer

valve springs,

and

valve spring lower collar.

Withdraw the valves from their guides, keeping them

in their relative positions when removed from the

~ngine

to

ensure replacement in their original valve guides.

The

valves are numbered on their heads I to 8, commencing

from the front

of

the engine.

If

new valves are fitted they

should be identified in a similar manner.

To

replace,

fit

each valve mto its guide and install the

lower collar, inner and outer valve springs, valve guide

shroud, and valve spring cap.

Compress the valve springs and

fit

a new oil seal to the

valve stem in the bottom of-the spring cap retainer groove.

Do not refit the old seals or oil-tightness may

be

lost,

with

consequent increased oil consumption.

It

will

be

food

that

the

new

seals are more easily fitted

if

they are soaked

iD

engine oil for a short time before use.

Refit the valve spring retainers, remove the valve spring

compressor, and replace the retainer circlip.

Owing

to

the limited clearance between the crowns

of

the pistons and the cylinder head joint face when the

pistons are in the T.D.C. position it is imperative

that

the

top faces

of

the valve heads 'stand down'

·018

to

·038

in.

(·46 to

·96

mm.) below the joint face

of

the cylinder head.

The dimension is checked by placing a straight-edge

across the cylinder head

joint

face

and

measuring the

clearance between the under side

of

the straight-edge

and

the top faces

of

the valves. Valves having a stand-down

clearance greater

than

the above limit may adversely

affect the engine compression

and

should be renewed.

i~

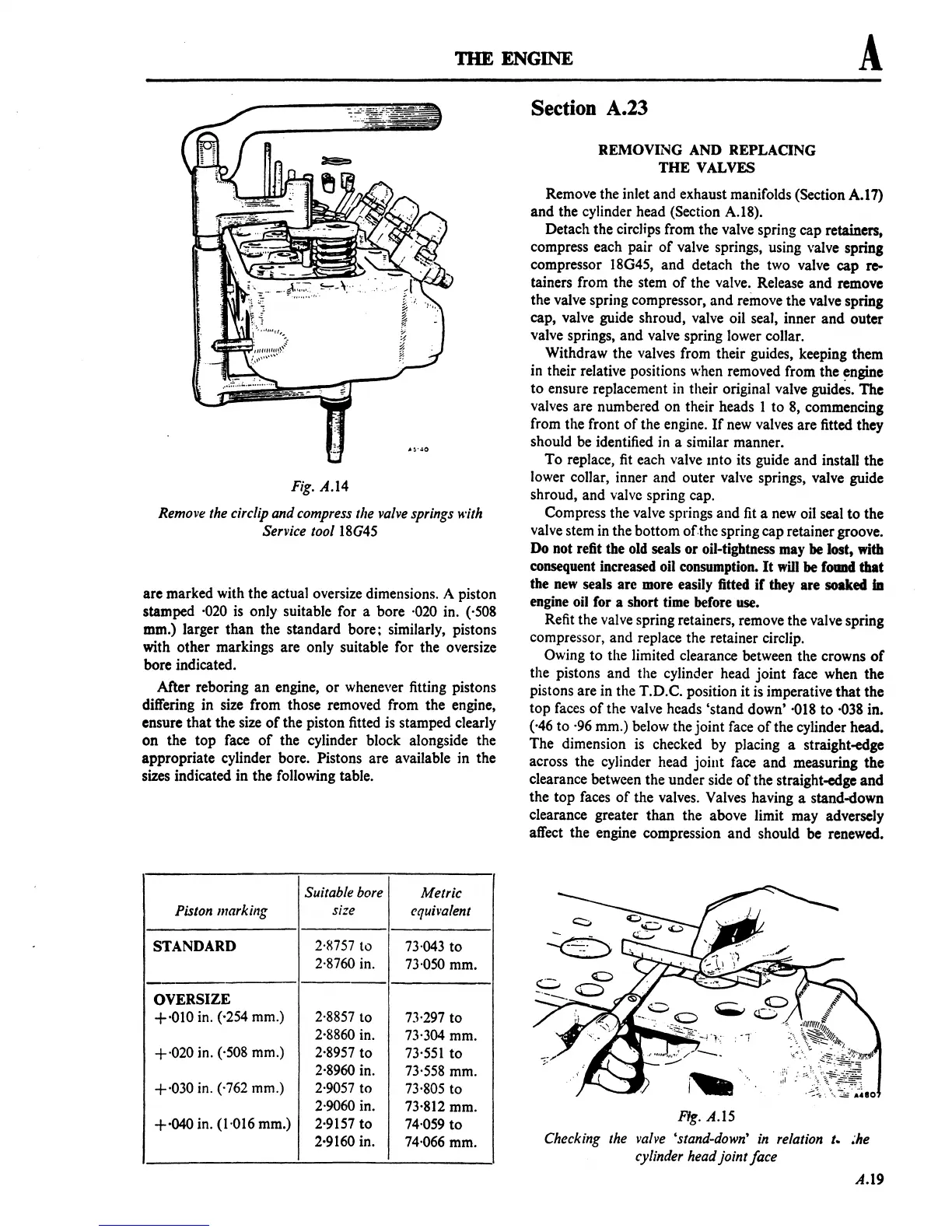

Fig.

A.15

Checking the valve 'stand-down'

in

relation t.

~he

cylinder head joint face

A.19

Loading...

Loading...