A

THE ENGINE

A4839

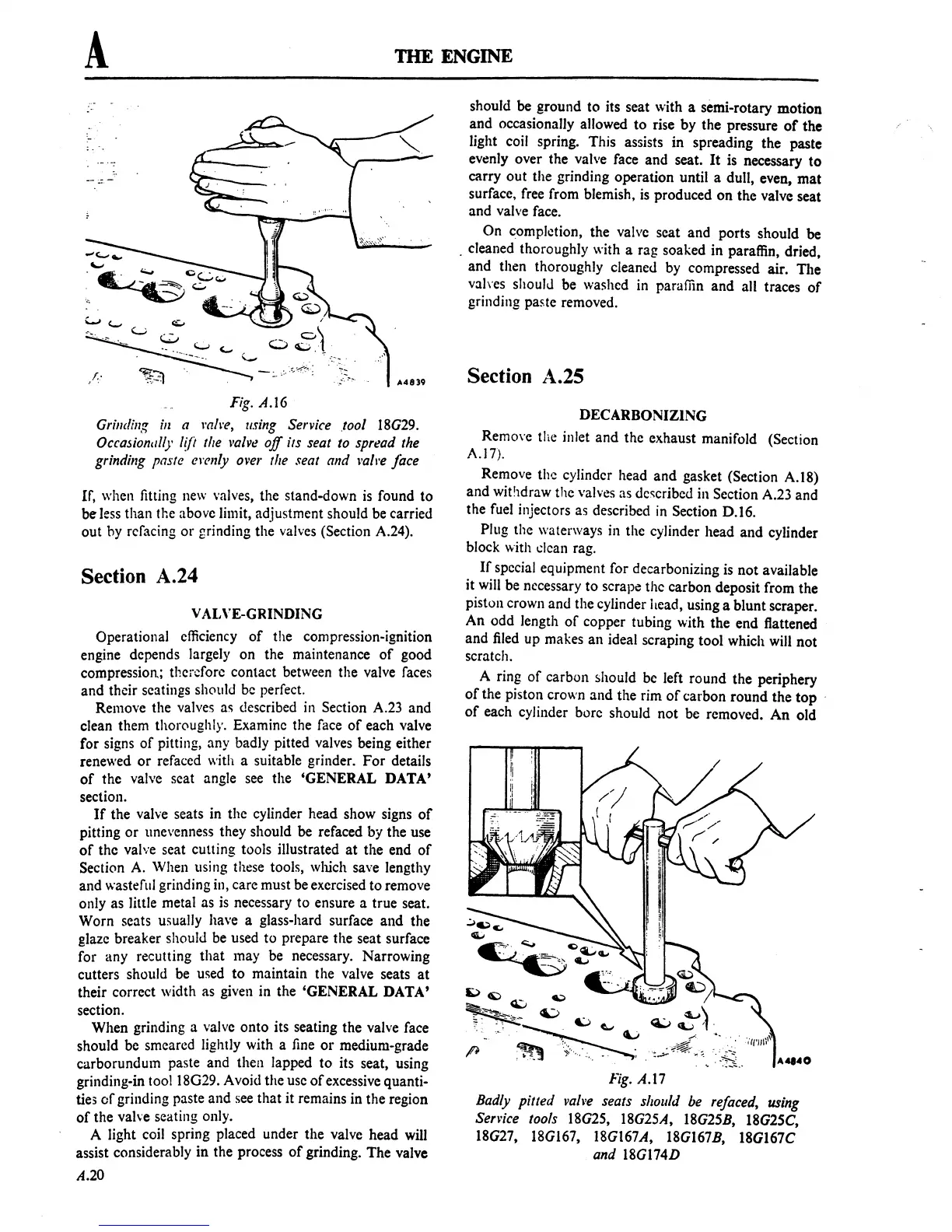

Fig. A.16

Grinding

ill

a

l'(!/re,

using Service .tool

18G29.

Occasionlllly

[{Ii

the l'alve

off

its seat to spread the

grinding

paste cl'£'"ly over the seat and

l'Q!J'e

face

If, when fitting

new

valves, the stand-down

is

found to

be

less

than the above limit, adjustment should be carried

out hy refacing

or

grinding the valves (Section A.24).

Section A.24

v AINE-GRINDING

Operational efficiency

of

the compression-ignition

engine depends largely on the maintenance

of

good

compression; therefore contact between the valve faces

and their seatings should

be

perfect.

Remove the valves

as described

in

Section A.23 and

clean them thoroughly. Examine the face

of

each valve

for signs

of

pitting, any badly pitted valves being either

renewed

or

refaced with a suitable grinder.

For

details

of

the valve scat angle

see

the 'GENERAL DATA'

section.

If

the valve seats in the cylinder head show signs

of

pitting

or

unevenness they should be

ref

aced

by

the use

of

the valve seat cutting tools illustrated

at

the end

of

Section

A.

When using these tools, which save lengthy

and wasteful grinding in, care must be exercised to remove

only as little metal as

is

necessary to ensure a true seat.

Worn seats u5ually have a glass-hard surface and the

glaze breaker should

be

used to prepare the seat surface

for any recutting that may be necessary. Narrowing

cutters should

be

used to maintain the valve seats

at

their correct width as given in the 'GENERAL DATA'

section.

When grinding a valve onto its seating the valve face

should be smeared lightly with a

fine

or

medium-grade

carborundum paste and then lapped to its seat, using

grinding-in too118G29. Avoid the usc

of

excessive quanti-

ties

of

grinding paste and

see

that it remains in the region

of

the valve seating only.

A light coil spring placed under the valve head

will

assist considerably in the process

of

grinding. The valve

04.20

should be ground to its seat with a semi-rotary motion

and occasionally allowed to rise by the pressure

of

the

light coil spring. This assists in spreading the paste

evenly over the valve face and seat.

It

is necessary

to

carry out the grinding operation until a dull, even, mat

surface, free from blemish,

is

produced on the valve seat

and valve face.

On completion, the valve seat and ports should be

. cleaned thoroughly with a rag soaked in paraffin, dried,

and then thoroughly cleaned by compressed air. The

vah'es should be washed

in

paraffin and all traces

of

grinding paste removed.

Section A.25

DECARBONIZING

Remo\'e

the inlet and the exhaust manifold (Section

A.17).

Remove the cylinder head and gasket (Section A.l8)

and withdraw the

valves as

de~cribed

in Section A.23 and

the

fuel

injectors as described

in

Section D.16.

Plug the waterways in the cylinder head and cylinder

block with

dean

rag.

If

special equipment for decarbonizing is not available

it

will

be necessary to scrape thc carbon deposit from the

piston crown and the cylinder head, using a blunt scraper.

An odd length

of

copper tubing with the end flattened

and

filed

up makes an ideal scraping tool which will not

scratch.

A ring

of

carbon should

be

left round the periphery

of

the piston crown and the rim

of

carbon round the top ,

of

each cylinder bore should not be removed.

An

old

10:)

~

Q.:,

~

~

~

6:,)

~--,:~

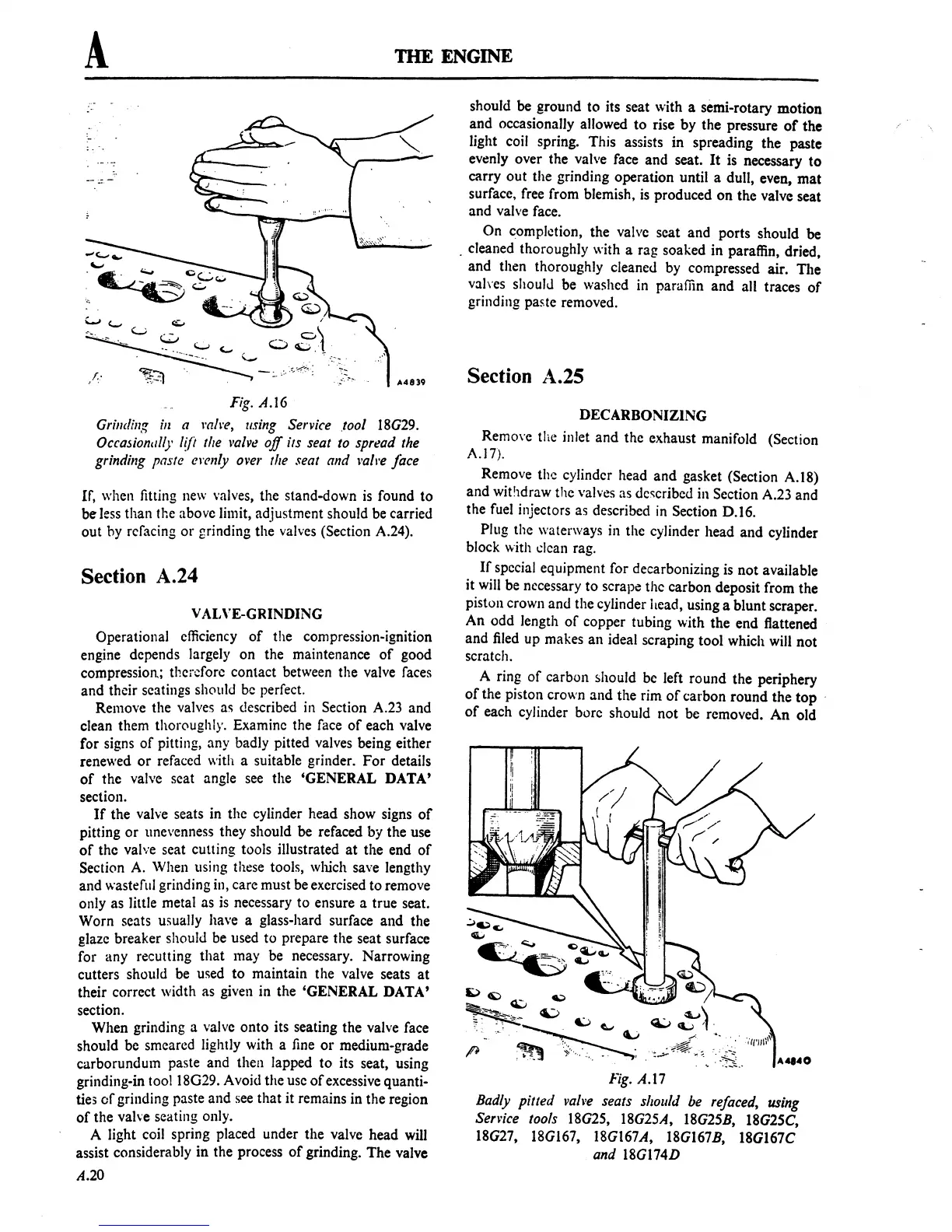

Fig. A.17

Badly

pitted

vall'e seats should be refaced, using

Senice

tools

18G25,

18G25A, 18G25B, 18G25C,

18G27, 18G167, 18G167A, 18G167B, 18G167C

and

18G174D

Loading...

Loading...