THE ENGINE

A

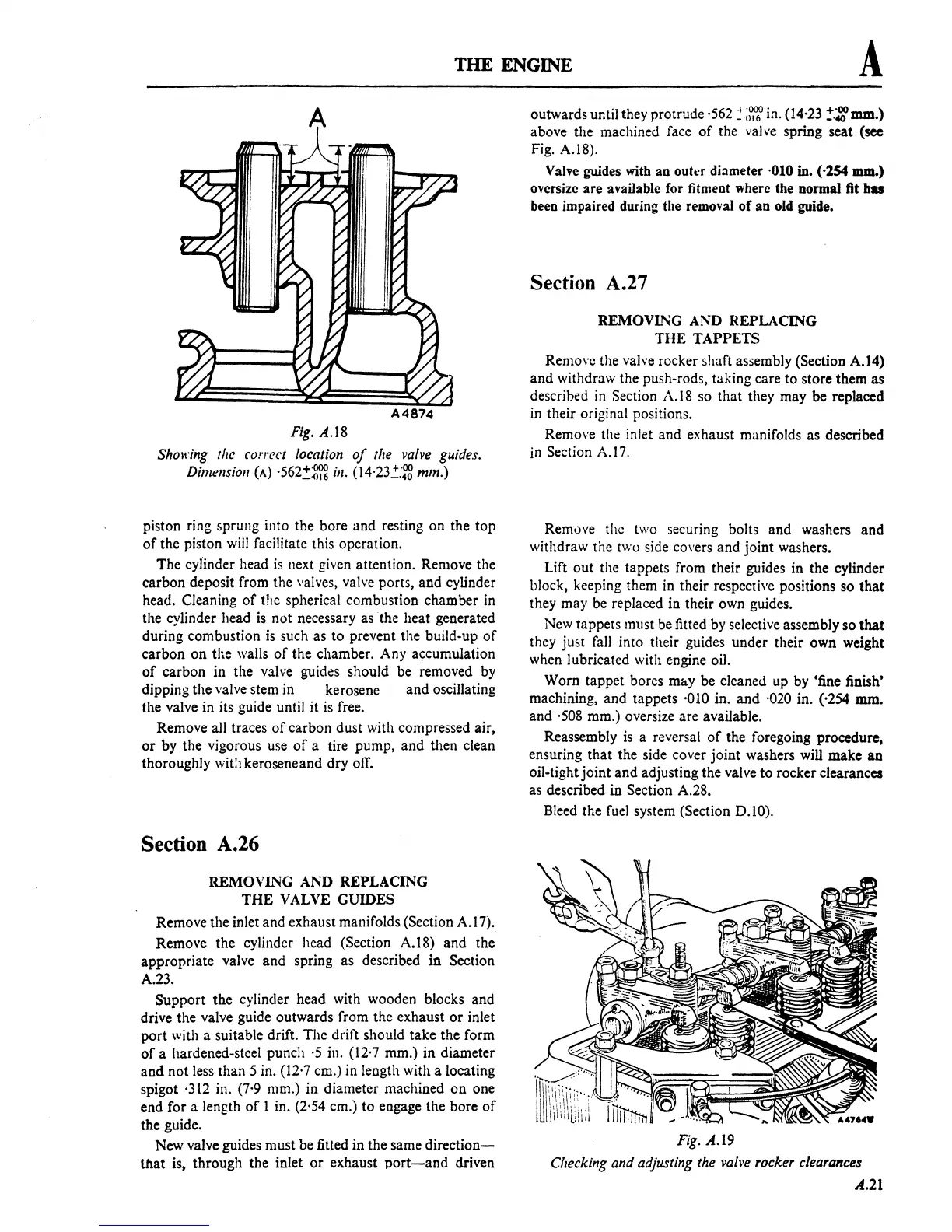

Fig.

A.lS

Showing the correct location

of

the

valve

guides.

Dimension

(A)

'562!:m

ill.

(I4'23"::"~

mm.)

piston ring sprung into the bore and resting

on

the top

of

the piston will facilitate this operation.

The cylinder head

is

next given attention. Remove the

carbon deposit from the valves, valve ports, and cylinder

head. Cleaning

of

the spherical combustion chamber

in

the cylinder head

is

not necessary as the heat generated

during combustion

is

such as to prevent the build-up

of

carbon

on

the walls

of

the chamber. Any accumulation

of

carbon in the valve guides should be removed by

dipping the valve stem in kerosene and oscillating

the valve in its guide until it

is

free.

Remove all traces

of

carbon dust with compressed air,

or

by the vigorous use

of

a tire pump, and then clean

thoroughly with kerosene and dry off.

Section A.26

REMOVL"IG AND REPLACING

THE

VALVE GUIDES

Remove the inlet and exhaust manifolds

(Section A. I 7).

Remove the cylinder head

(Section A.IS) and the

appropriate valve and spring as described

in

Section

A.23.

Support the cylinder head with wooden blocks and

drive the valve guide outwards from the exhaust

or

inlet

port

with a suitable drift. The drift should take the form

of

a hardened-steel punch

·5

in. (12'7 mm.) in diameter

and

not

less than 5 in. (12'7 em.) in length with a locating

spigot

·312 in. (7'9 mm.) in diameter machined

on

one

end for a length

of

I in. (2'54 cm.) to engage the bore

of

the guide.

New valve guides must be fitted in the same

direction-

that

is, through the inlet

or

exhaust

port-and

driven

outwards until they protrude

·562 :

~~

in. (14·23

!.;:mm.)

above the machined face

of

the valve spring seat (see

Fig. A.18).

Valve guides

with

an outer diameter ·010 in. ('254 mm.)

oversize are available for fitment where the normal

fit

bas

been impaired during the removal

of

an old guide.

Section A.27

REMOVING AND REPLACING

THE

TAPPETS

Remove the valve rocker

shan

assembly (Section

A.l4)

and withdraw the push-rods, taking care to store them

as

described

in

Section

A.18

so that they may

be

replaced

in

their original positions.

Remove

the inlet and exhaust manifolds as described

in Section A.17.

Remove the two securing bolts and washers and

withdraw the two side

covers and joint washers.

Lift out the tappets from their guides in the cylinder

block, keeping them

in

their respective positions so

that

they may be replaced in their own guides.

New tappets must

be

fitted by selective assembly so

that

they just fall into their guides under their own weight

when lubricated with engine oil.

Worn tappet bores

mlly be cleaned up by 'fine finish'

machining, and tappets ·010 in. and ·020 in. (·254

mm.

and

·508

mm.) oversize are available.

Reassembly

is

a reversal

of

the foregoing procedure,

ensuring that the side cover joint washers will make

an

oil-tight

joint

and adjusting the valve to rocker clearances

as described in Section A.28.

Bleed the fuel system

(Section 0.10).

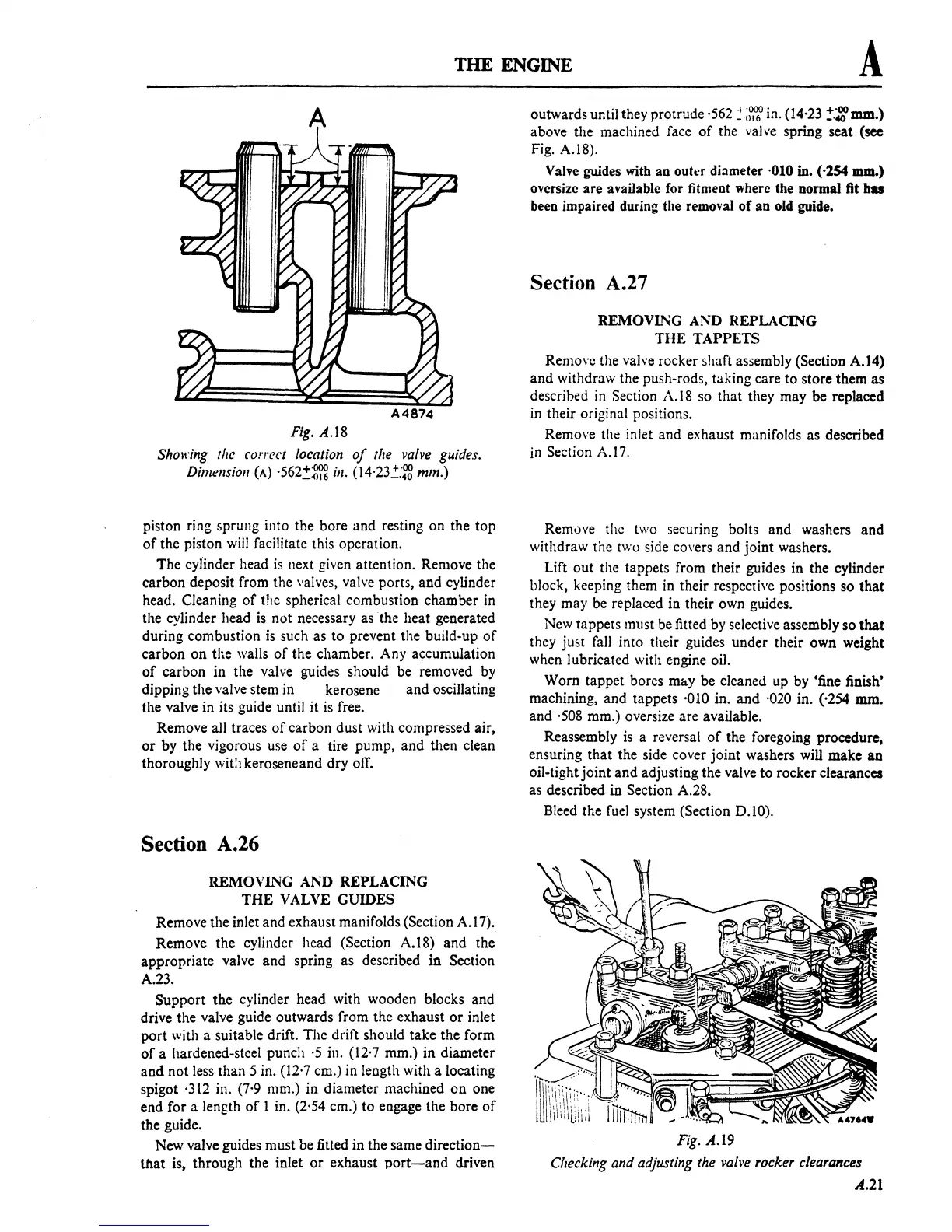

Fig.

A.I9

Cbecking and adjusting the vahe rocker clearances

A.21

Loading...

Loading...