A

THE ENGINE

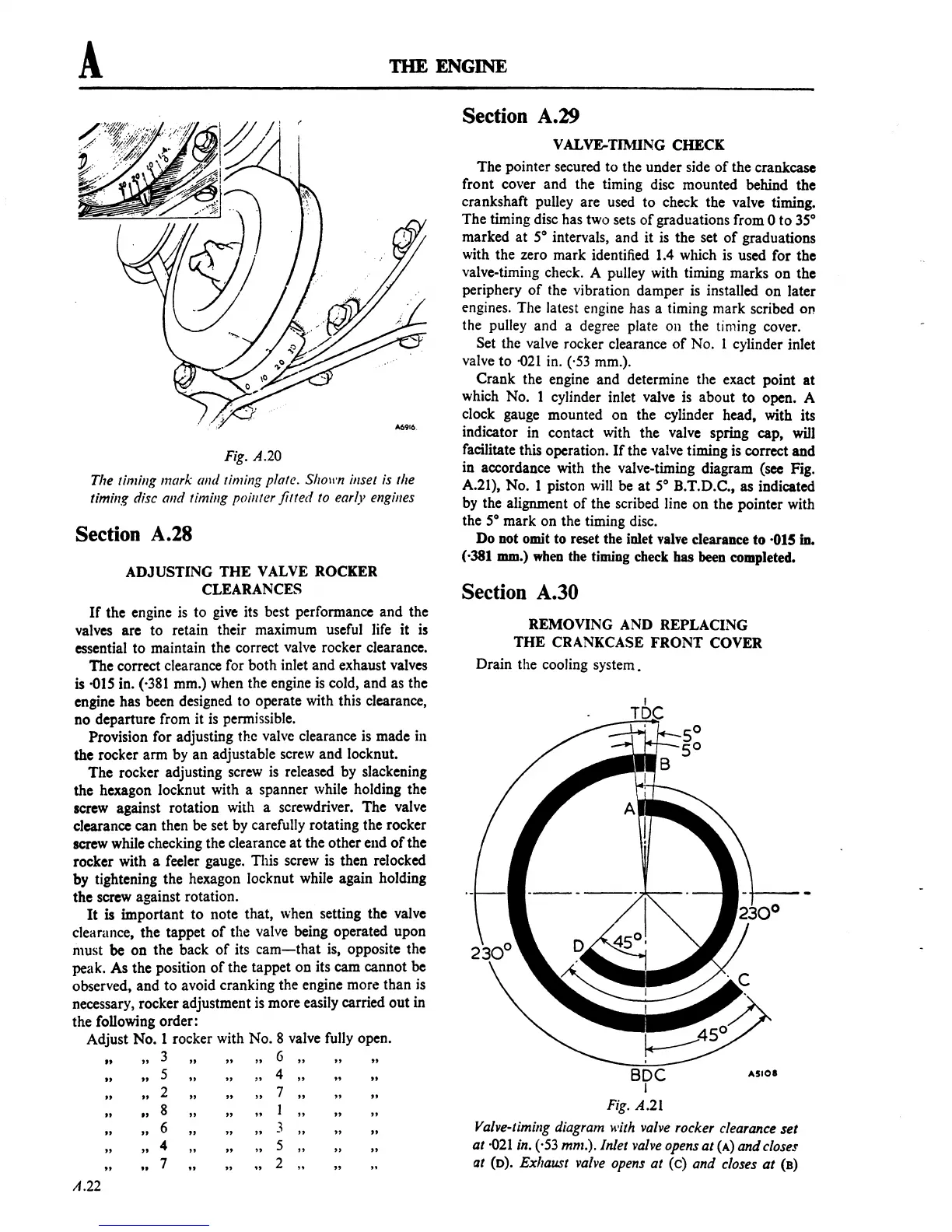

Fig. A.20

The timing mark and timing plate. Sholl'n inset is the

timing disc and timing poill1er fitted to early engilles

Section A.28

ADJUSTING

THE

VALVE ROCKER

CLEARANCES

If

the engine is

to

give its best performance and the

valves

arc to retain their maximum useful life it is

essential

to

maintain the correct valve rocker clearance.

The correct clearance for both inlet and exhaust valves

is

-015

in. (·381 mm.) when the engine

is

cold, and as the

engine has been designed

to

operate with this clearance,

no departure from it is permissible.

Provision for adjusting the valve clearance is made ill

the rocker arm by

an

adjustable screw and locknut.

The

rocker adjusting screw

is

released by slackening

the hexagon locknut with a spanner while holding the

screw

against rotation with a screwdriver. The valve

clearance can then be set by carefully rotating the rocker

screw

while checking the clearance

at

the other end

of

the

rocker with a feeler gauge. This screw is then relocked

by tightening the hexagon locknut while again holding

the screw against rotation.

It

is important

to

note that, when setting the valve

clearance, the tappet

of

the valve being operated upon

must be

on

the back

of

its

cam-that

is, opposite the

peak. As the position

of

the tappet

on

its

cam

cannot be

observed, and

to

avoid cranking the engine more than is

necessary, rocker adjustment

is

more easily carried out in

the following order:

Adjust

No.1

rocker with

No.8

valve fully open.

"

"3,,

""6,,

" "

It

"5,,

"4,,

"

"

"2,,

""7,,

" "

"

.,8"

""1,,

" "

"

,,6

" "

3"

" "

"

"4,,

""5,,

" "

",,7

.,2""

A.22

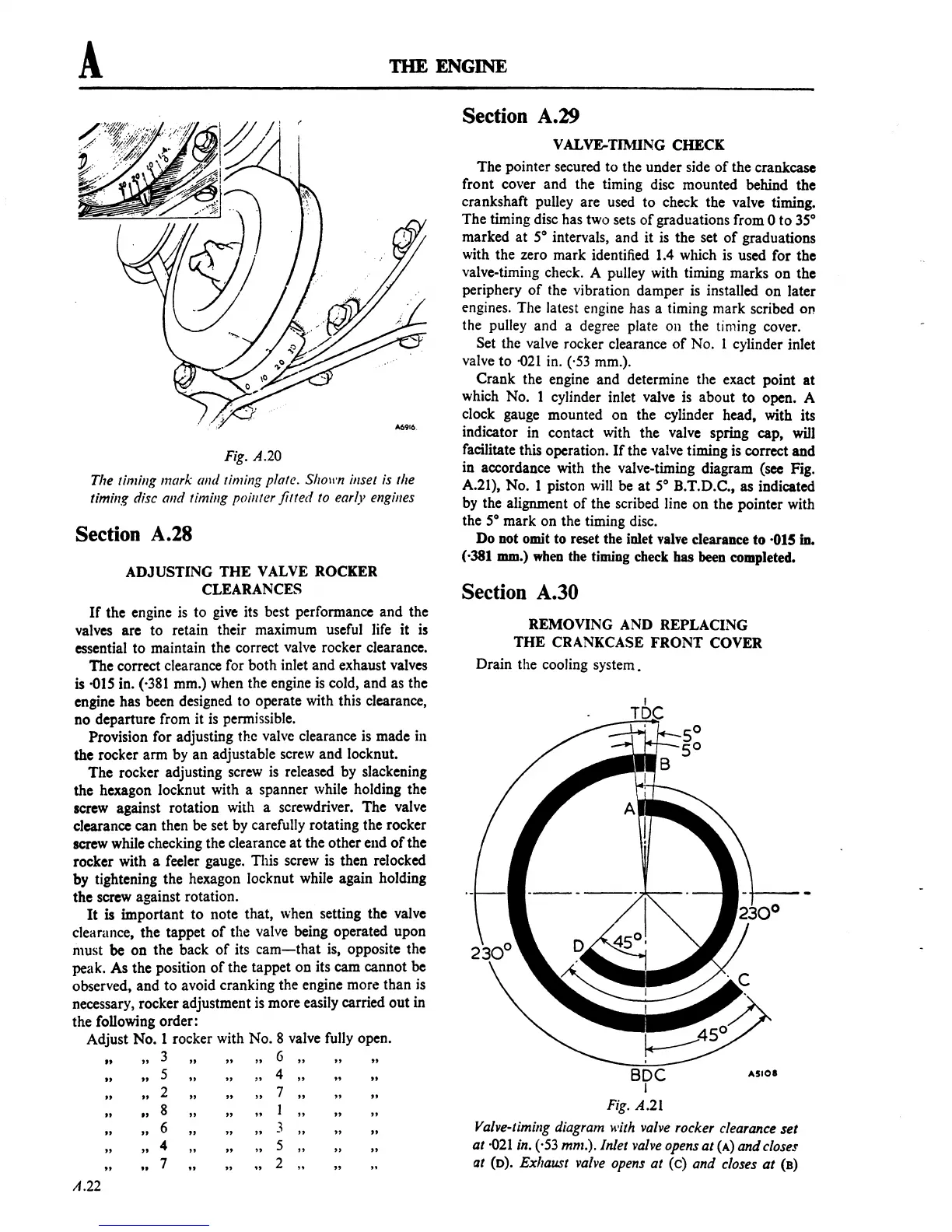

Section A.29

VALVE-TIMING CHECK

The pointer secured

to

the under side

of

the crankcase

front cover and the timing disc mounted behind the

crankshaft pulley are used

to

check the valve timing.

The timing disc has two sets

of

graduations from 0

to

35°

marked

at

5°

intervals, and it

is

the set

of

graduations

with the zero mark identified

1.4

which

is

used for the

valve-timing check. A pulley with timing marks on the

periphery

of

the vibration damper

is

installed on later

engines. The latest engine has a timing mark scribed on

the pulley and a degree plate 011 the timing cover.

Set the valve rocker clearance

of

No.1

cylinder inlet

valve

to

-021

in. ('53 mm.).

Crank the engine and determine the exact point

at

which No. 1 cylinder inlet valve is about

to

open. A

clock gauge mounted on the cylinder head, with its

indicator in contact with the valve spring cap,

will

facilitate this operation.

If

the valve timing is correct and

in accordance with the valve-timing diagram (sec Fig.

A.21), No. 1 piston will be

at

5°

B.T.D.C

.•

as

indicated

by the alignment

of

the scribed line

on

the pointer with

the

5°

mark on the timing disc.

Do

not omit to reset the inlet valve clearance

to

·015 in.

(,381

IDOl.)

when the timing check bas been completed.

Section A.30

REMOVING AND REPLACING

THE

CRANKCASE

FRONT

COVER

Drain the cooling system.

SDC

I

Fig.

A.21

ASiOI

Valve-timing diagram with valve rocker clearance

set

at

·021

in. (·53

mm.).lnlet

valve opens

at

(A)

and

closes

at

(D).

Exhaust valve opens

at

(c)

and

closes

at

(8)

Loading...

Loading...