THE ENGINE

A

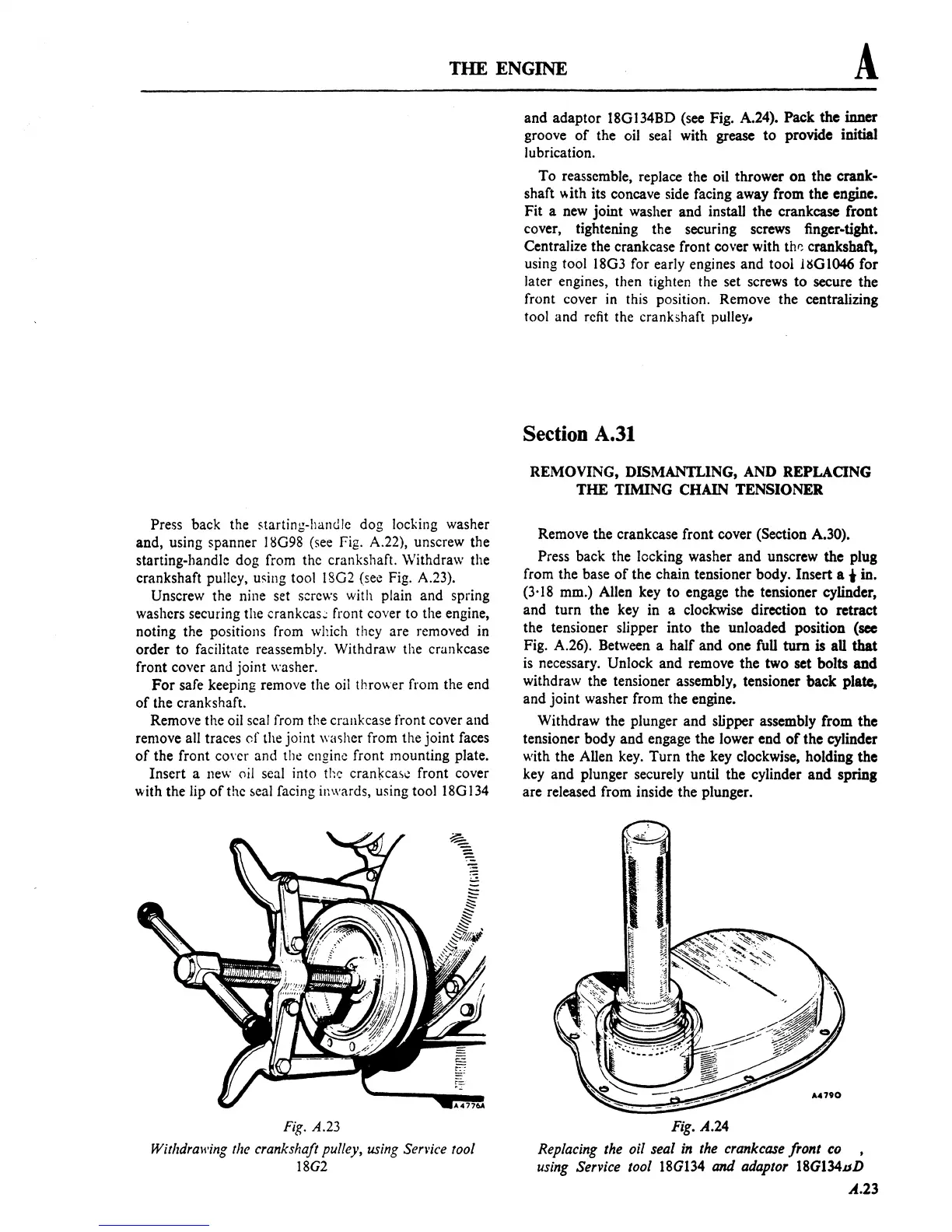

Press back the starting-handle dog locking washer

and, using spanner

18G98

(see Fig. A.22), unscrew the

starting-handle dog from the crankshaft.

Withdraw the

crankshaft pulley,

u!'ing tool 18G2 (see Fig. A.23).

Unscrew the nine set screws with plain and spring

washers securing the

crankcas~

front cover to the engine,

noting the positions from which they are removed in

order to facilitate reassembly. Withdraw the crankcase

front cover and joint washer.

For

safe keeping remove the oil thrower from the end

of

the crankshaft.

Remove the oil seal from the crankcase front cover and

remove all traces

or

the joint washer from the joint faces

of

the front co\'er and the engine front mounting plate.

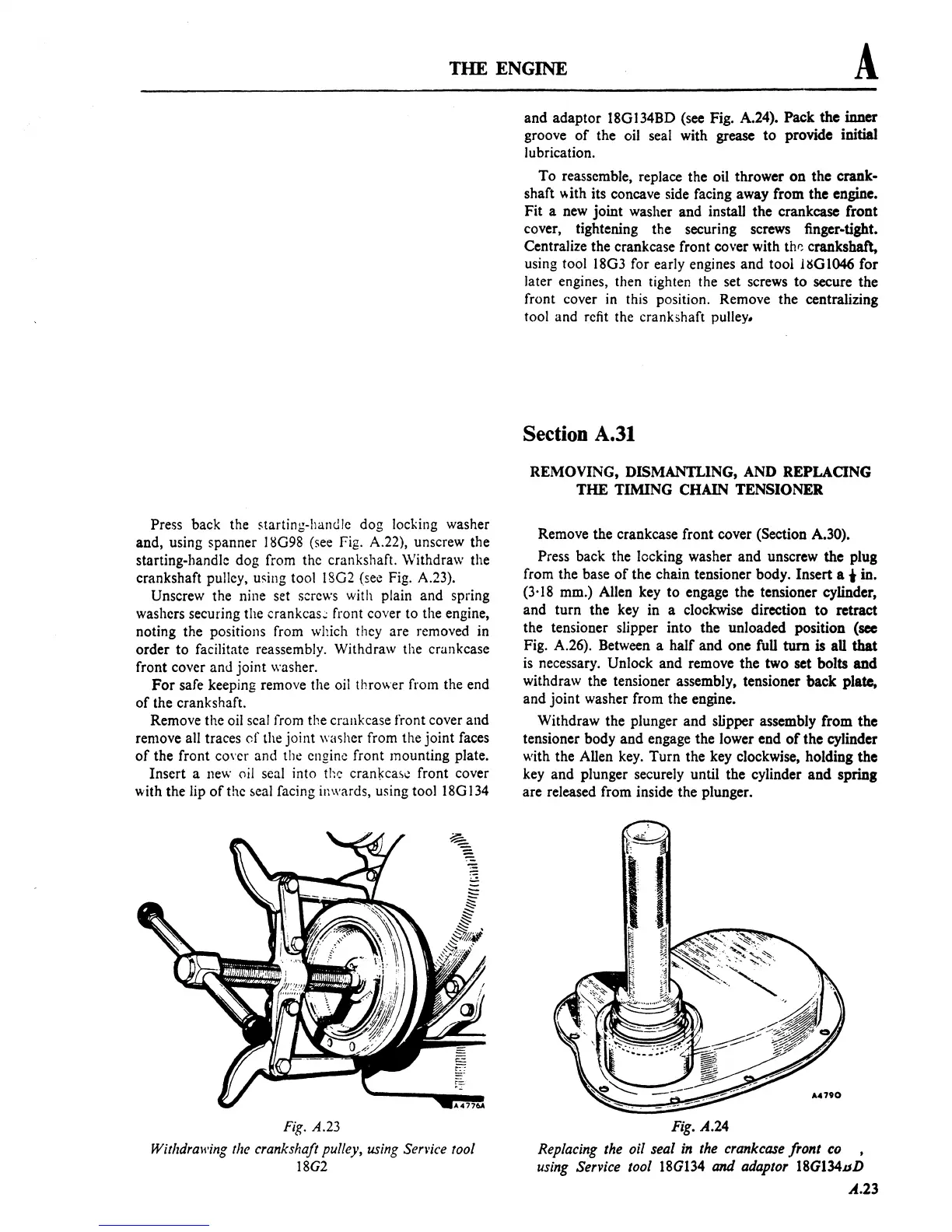

Insert a

new

oil seal into the

cran~ca,e

front cover

with the lip

of

the

5eal

facing inwards, using tool

18G

134

Fig.

A.23

Withdrawing the crankshaft pulley, using Sen'ice tool

18G2

and adaptor 18Gl34BD (see Fig. A.24). Pack the inner

groove

of

the oil seal with

grease

to

provide initial

lubrication.

To reassemble, replace the oil thrower

on

the crank-

shaft

y,ith its concave side facing away from the engine.

Fit a

new

joint washer and install the crankcase front

cover, tightening the securing screws finger-tight.

Centralize the crankcase front

cover with

thr:

crankshaft,

using tool 18G3 for early engines and tool

HSGI046

for

later engines, then tighten the set screws

to

secure the

front cover in this position. Remove the centralizing

tool and refit the crankshaft pulley.

Section A.31

REMOVING, DISMANTLING, AND REPLACING

THE

TIMING CHAIN TENSIONER

Remove the crankcase front cover (Section A.30).

Press back the locking washer and unscrew the plug

from the base

of

the chain tensioner body. Insert a

..

in.

(3·18 mm.) Allen key to engage the tensioner cylinder,

and turn the key in a clockwise direction

to

retract

the tensioner slipper into the unloaded position (see

Fig. A.26). Between a half and one

fuU

tum

is

aU

that

is

necessary. Unlock and remove the two set bolts

and

withdraw the tensioner assembly, tensioner back plate,

and joint washer from the engine.

Withdraw the plunger and slipper assembly from the

tensioner body and engage the lower end

of

the cylinder

with the Allen

key.

Turn the key clockwise, holding the

key and plunger securely until the cylinder

and

spring

are released from inside the plunger.

Fig.

A.24

Replacing the oil seal

in

the crankcase front

co

,

using Service tool

18G134

and

adaptor 18G134DD

A.23

Loading...

Loading...