A

THE ENGINE

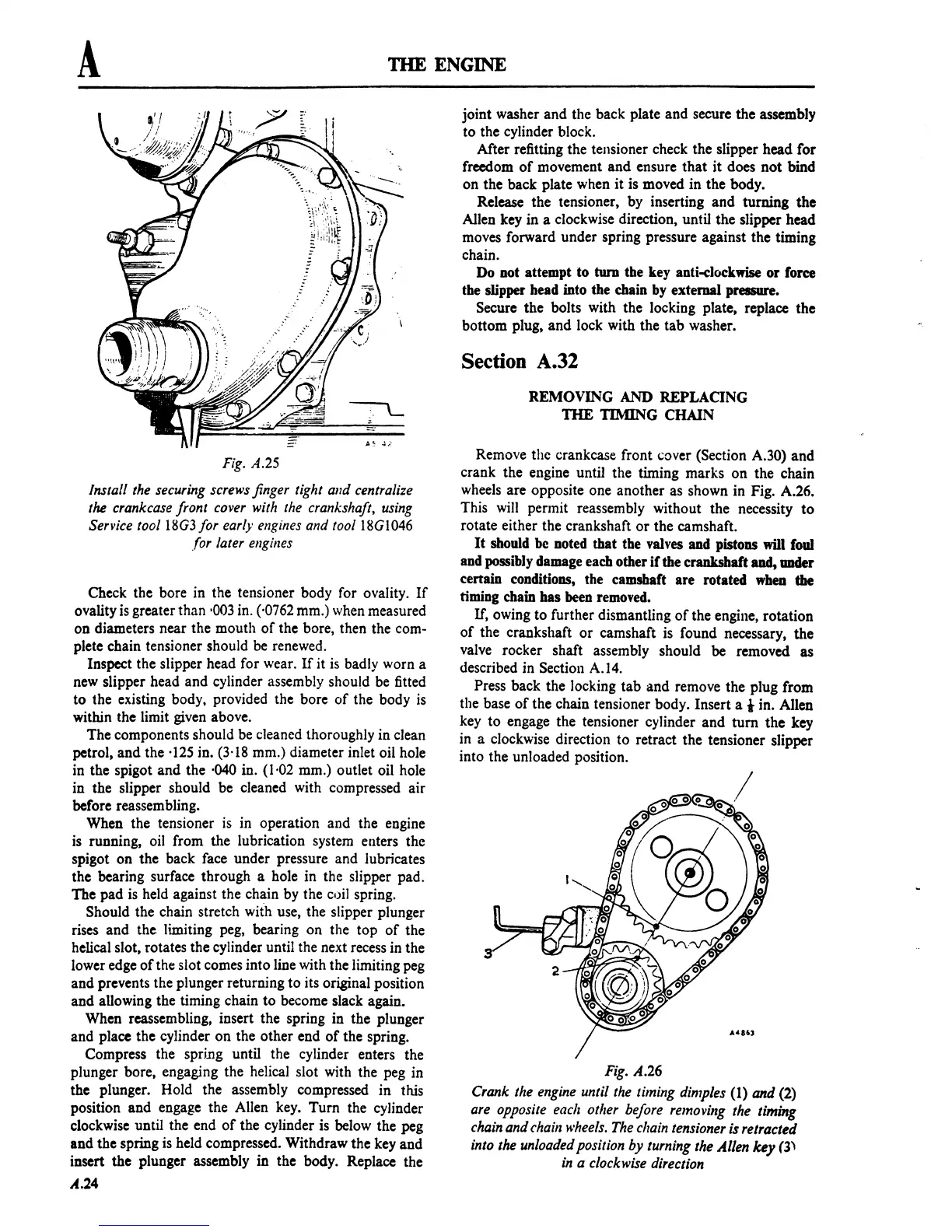

Fig.

A.25

Install

the

securing

screws

finger tight

and

centralize

the

crankcase

front

cover

with

the

crankshaft,

using

Service

tool 18G3/or

early

engines

and

tool 18GI046

for

later

engines

Check the bore in the tensioner body for ovality.

If

ovality

is

greater than

·003

in. (·0762 mm.) when measured

on

diameters near the mouth

of

the bore, then the com-

plete chain tensioner should be renewed.

Inspect the slipper head for wear.

If

it is badly worn a

new slipper head and cylinder assembly should be fitted

to the existing body, provided the bore

of

the body is

within the limit given above.

The components should be cleaned thoroughly in clean

petrol,

and

the ·125 in. (3·18 mm.) diameter inlet oil hole

in the spigot

and

the ·040 in.

(I

·02

mm.) outlet oil hole

in the slipper should be cleaned with compressed air

before reassembling.

When the tensioner

is

in operation and the engine

is

running, oil from the lubrication system enters the

spigot on the back face under pressure and lubricates

the bearing surface through a hole in the slipper pad.

The pad

is

held against the chain by the CI)i1 spring.

Should the chain stretch with use, the slipper plunger

rises and the limiting peg, bearing

on

the top

of

the

helical slot, rotates the cylinder until the next recess in the

lower edge

of

the slot comes into line with the limiting peg

and prevents the plunger returning

to

its original position

and allowing the timing chain

to

become slack again.

When reassembling, insert the spring in the plunger

and place the cylinder

on

the other end

of

the spring.

Compress the spring until the cylinder enters the

plunger bore, engaging the helical slot with the peg in

the plunger. Hold the assembly compressed in this

position and engage the Allen key. Turn the cylinder

clockwise until the end

of

the cylinder is below the peg

and the spring

is

held compressed. Withdraw the key and

insert the plunger assembly in the body. Replace the

"'.24

joint washer

and

the back plate and secure the assembly

to the cylinder block.

After refitting the tensioner check the slipper head for

freedom

of

movement

and

ensure

that

it does

not

bind

on

the back plate when

it

is moved

in

the body.

Release the tensioner, by inserting

and

turning

the

Allen

key

in a clockwise direction, until the slipper head

moves forward under spring pressure against the timing

chain.

Do

not attempt to turn the key anti-dockwise

or

force

the sUpper head into the chain by external pressure.

Secure the bolts with the locking plate, replace the

bottom plug,

and

lock with the

tab

washer.

Section A.32

REMOVING AND REPLACING

THE

TIMING

CHAIN

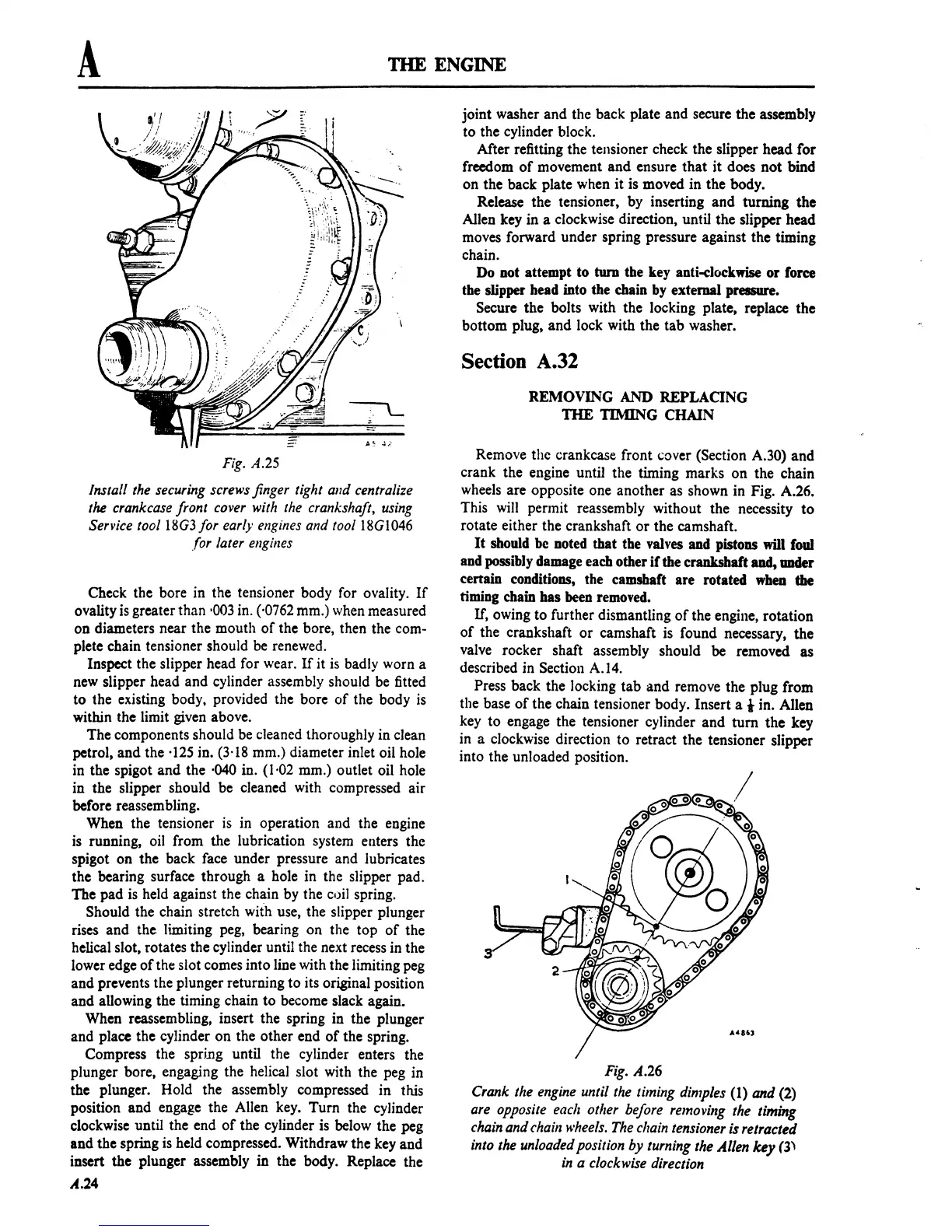

Remove thc crankcase front

,over

(Section A.30) and

crank the

engine until the timing marks

on

the chain

wheels are opposite one another as shown in Fig. A.26.

This will permit reassembly without the necessity

to

rotate either the crankshaft

or

the camshaft.

It

should be

Doted

that the valves and pistons will foul

and possibly damage

each other

if

the crankshaft and, under

certain conditions, the camshaft are rotated when the

timing chain has

been

removed.

If,

owing to further dismantling

of

the engine, rotation

of

the crankshaft

or

camshaft is found necessary, the

valve rocker shaft assembly should be removed as

described in Section

A.14.

Press back the locking

tab

and

remove the plug from

the base

of

the chain tensioner body. Insert a i in. Allen

key

to

engage the tensioner cylinder

and

tum

the

key

in a clockwise direction

to

retract the tensioner slipper

into the unloaded position.

Fig.

A.26

Crank

the

engine

until

the

timing

dimples

(1)

and

(2)

are

opposite

each

other

before

removing

the

timing

chain

and

chain

wheels.

The

c/rain

tensioner

is

retracted

into

the

unloaded

position by

turning

the Allen key (3'

in

a

clockwise

direction

Loading...

Loading...